Method for catalytically preparing polycarbonate

A polycarbonate, catalytic preparation technology, applied in the field of catalytic preparation of polycarbonate, can solve the problems of restricting the application of polycarbonate, product metal residue pollution and other problems, achieve the suppression of side reactions of methylation, improve the poor universality, Good catalytic selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

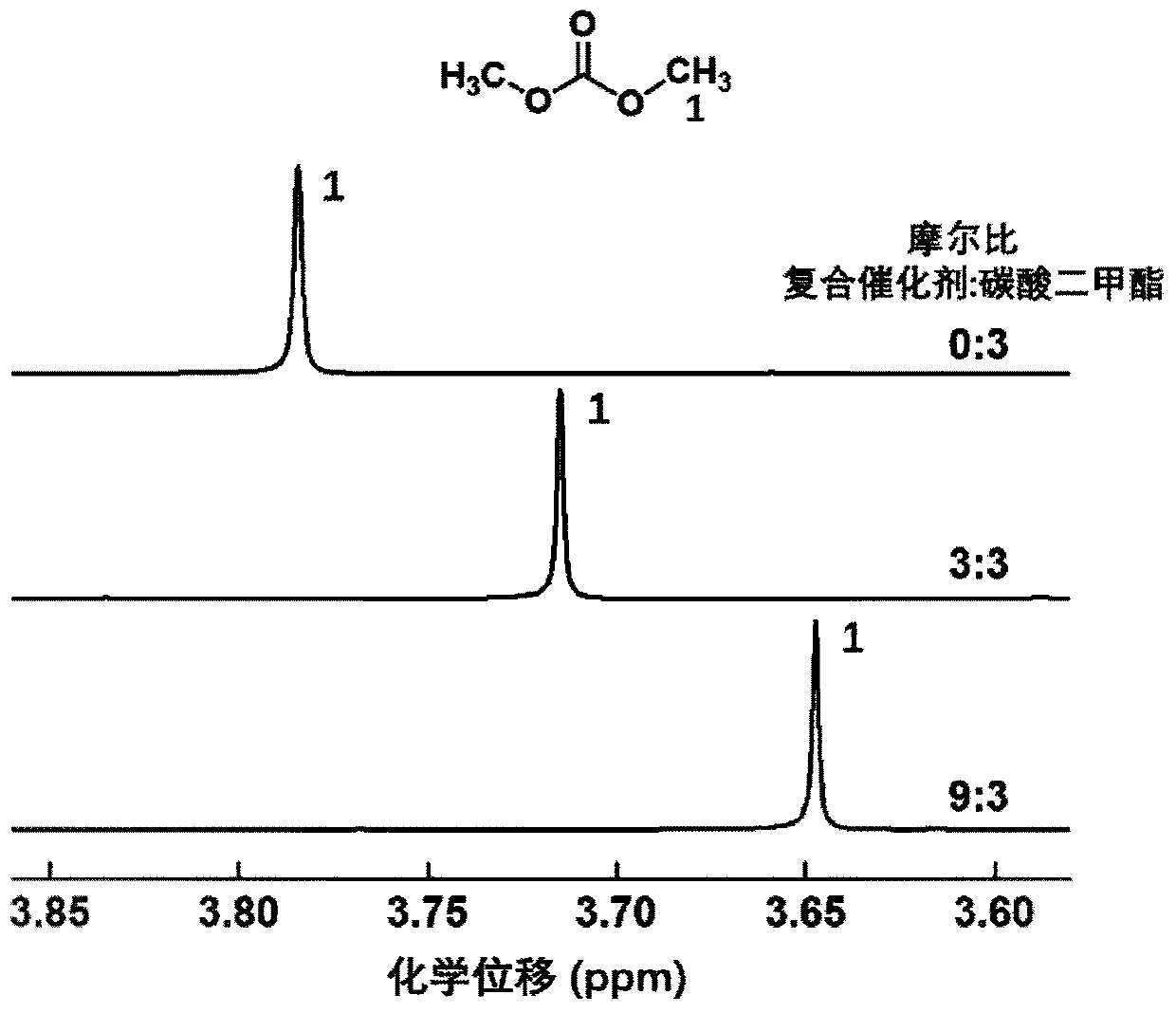

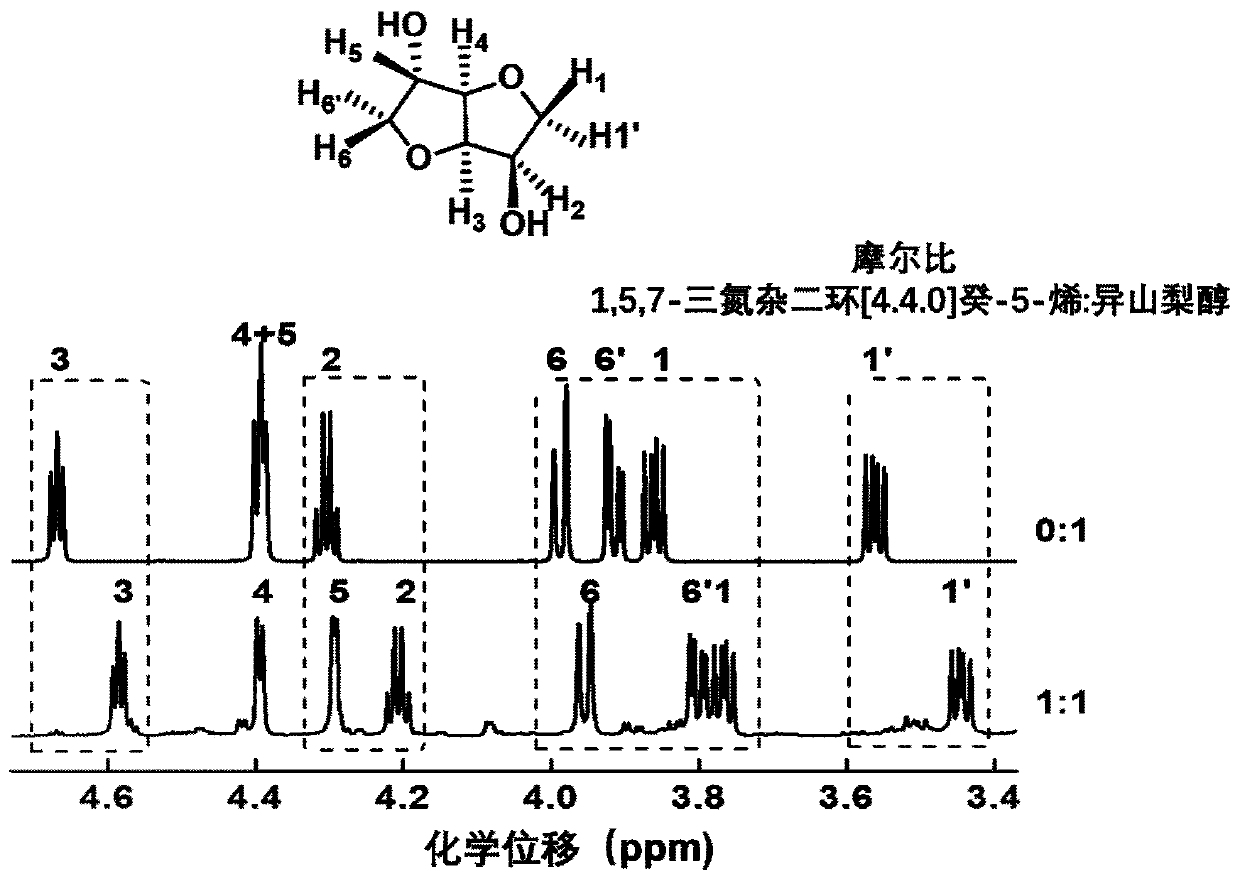

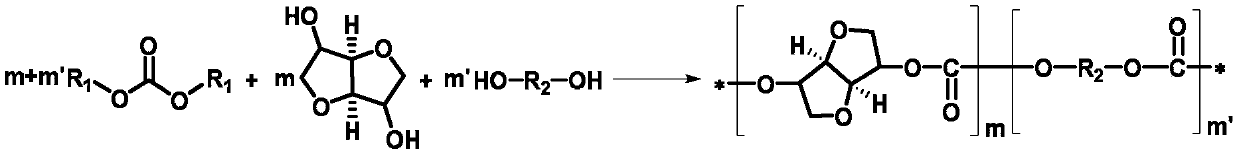

[0054] In this example, isosorbide and dimethyl carbonate were used as raw materials to prepare a polycarbonate under the composite catalysis of cellulose and 1,5,7-triazabicyclo[4.4.0]dec-5-ene. ester, the reaction formula is as follows:

[0055]

[0056] The preparation method comprises the following steps:

[0057] (1) Transesterification stage: Add 14.6g (0.1mol) isosorbide and 63g (0.7mol) dimethyl carbonate in the reaction flask, 1,5,7-triazabicyclo[4.4 .0]dec-5-ene has a mass of 1.46×10 -2 g, the mass of cellulose is 1.46×10 -3 g, under a nitrogen atmosphere, react at 98°C under normal pressure for 6h, then slowly increase the temperature to 180°C, and react for 1h to volatilize unreacted dimethyl carbonate and low-boiling product methanol to obtain a prepolymer;

[0058] (2) Polycondensation stage: the temperature in step (1) is raised from 180°C to 240°C, the vacuum is slowly reduced to 50Pa, and the reaction is carried out for 4 hours to obtain the product isos...

Embodiment 2

[0062] The difference between this example and Example 1 is that the mass of 1,5,7-triazabicyclo[4.4.0]dec-5-ene in the composite catalyst is replaced by 4-dimethylaminopyridine, and other The conditions are exactly the same as in Example 1.

[0063] Molecular weight test: The GPC test result of the product shows that the number average molecular weight of polycarbonate M n 17000g / mol, weight average molecular weight M w It is 30000g / mol.

[0064] Thermal performance test: The DSC test results of the product show that the glass transition temperature T of polycarbonate g It is 148°C.

Embodiment 3

[0066] The difference between this example and Example 1 is that the mass of 1,5,7-triazabicyclo[4.4.0]dec-5-ene in the composite catalyst is replaced by 4-pyrrolidinopyridine, and other The conditions are exactly the same as in Example 1.

[0067] Molecular weight test: The GPC test result of the product shows that the number average molecular weight of polycarbonate M n 16000g / mol, weight average molecular weight M w It is 28000g / mol.

[0068] Thermal performance test: The DSC test results of the product show that the glass transition temperature T of polycarbonate g is 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com