CNF-based homologous heterogeneous photo-thermal material for seawater desalination and preparation method thereof

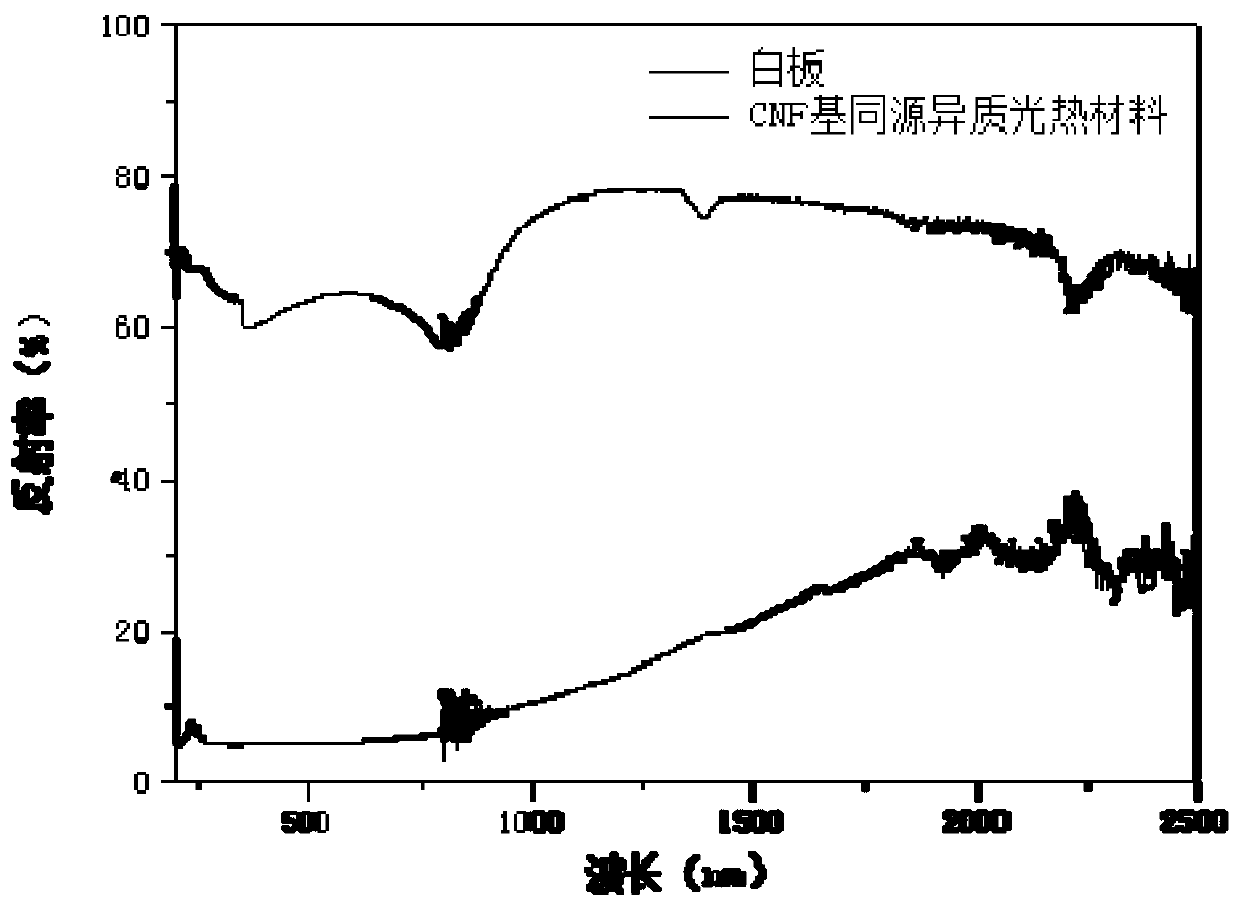

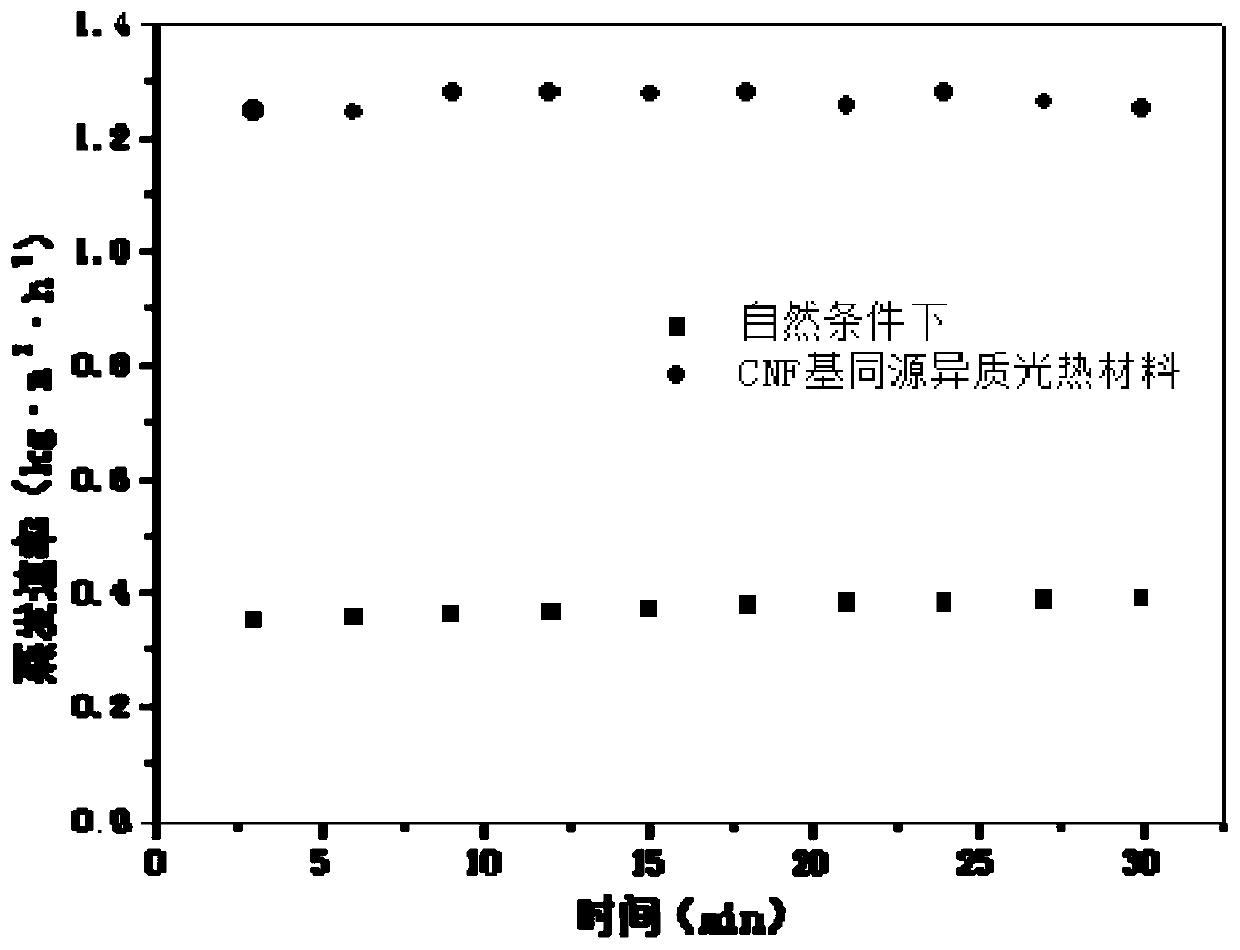

A heterogeneous, photothermal technology, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve problems such as incompatibility, poor interface bonding performance, etc., to achieve abundant raw materials, pollution-free, high-efficiency photothermal conversion and desalination of seawater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a preparation method of a CNF-based homogeneous heterogeneous photothermal material for seawater desalination, comprising the following steps:

[0025] Step 1, mixing nanocellulose, adhesive, cell regulator and water to prepare a mixed suspension; wherein, the contents of each component in the mixed suspension are: nanocellulose: 1-20wt%, glue Adhesive: 1-20wt%, cell regulator: 1-20wt%, and water: the rest, the total content of the above components is 100wt%;

[0026] Step 2. Foaming the mixed suspension by physical foaming to obtain a nanocellulose wet foam system; specifically, stirring the mixed suspension to allow air to enter the mixed suspension to form a nanocellulose wet foam system ;

[0027] Step 3. Perform directional freezing and drying on the nanocellulose wet foam system to obtain a nanocellulose-based foam material; wherein, the directional freezing time is 1 to 20 hours, and the freezing temperature is -80°C to -18°C; the drying p...

Embodiment 1

[0033] Embodiment 1 provides a preparation method of a CNF-based homogeneous heterogeneous photothermal material for seawater desalination, comprising the following steps:

[0034] Step 1. Mix nanocellulose, adhesive, cell regulator and water to prepare a mixed suspension; the contents of each component in the mixed suspension are: nanocellulose: 1wt%, adhesive : 20wt%, cell regulator: 20wt% and the balance of water, the total content of the above components is 100wt%;

[0035] Step 2, stirring the mixed suspension so that a large amount of air enters the mixed suspension to form a foam to obtain a nanocellulose wet foam system;

[0036] Step 3. Perform directional freezing and drying on the nanocellulose wet foam system to obtain a nanocellulose-based foam material; wherein, the directional freezing time is 1 hour, and the freezing temperature is -18° C.; the drying process is freeze-drying, and the freeze-drying time is 100 hours , the freeze-drying temperature is -50°C;

...

Embodiment 2

[0041] Embodiment 2 provides a preparation method of a CNF-based homogeneous heterogeneous photothermal material for seawater desalination, comprising the following steps:

[0042] Step 1. Mix nanocellulose, adhesive, cell regulator and water to prepare a mixed suspension; the contents of each component in the mixed suspension are: nanocellulose: 10wt%, adhesive : 1wt%, cell regulator: 20wt% and the rest of water, the total content of the above components is 100wt%;

[0043] Step 2, stirring the mixed suspension so that a large amount of air enters the mixed suspension to form a foam to obtain a nanocellulose wet foam system;

[0044] Step 3. Perform directional freezing and drying on the nanocellulose wet foam system to obtain a nanocellulose-based foam material; wherein, the directional freezing time is 20 hours, and the freezing temperature is -80°C; the drying process is freeze-drying, and the freeze-drying time is 10 hours , the freeze-drying temperature is -60°C;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com