Carrying structure and folding and unfolding method of work boat

A technology for working boats and lock tongues, which is applied in the directions of ships, ship fixing/storage, and ship propulsion, can solve the problems of unstable working boats, hidden dangers, scratches, etc., and achieves strong safety, controllability and cost. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

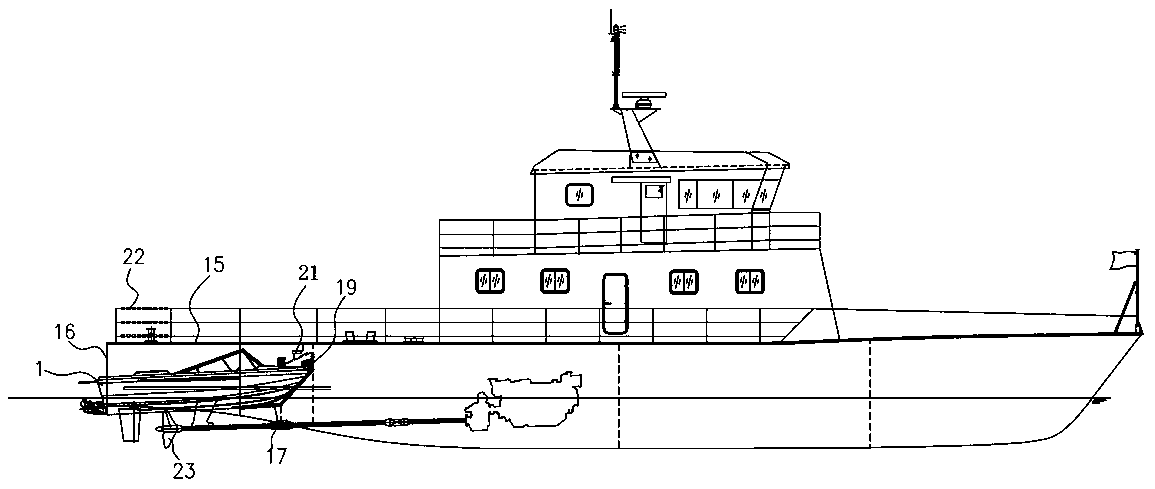

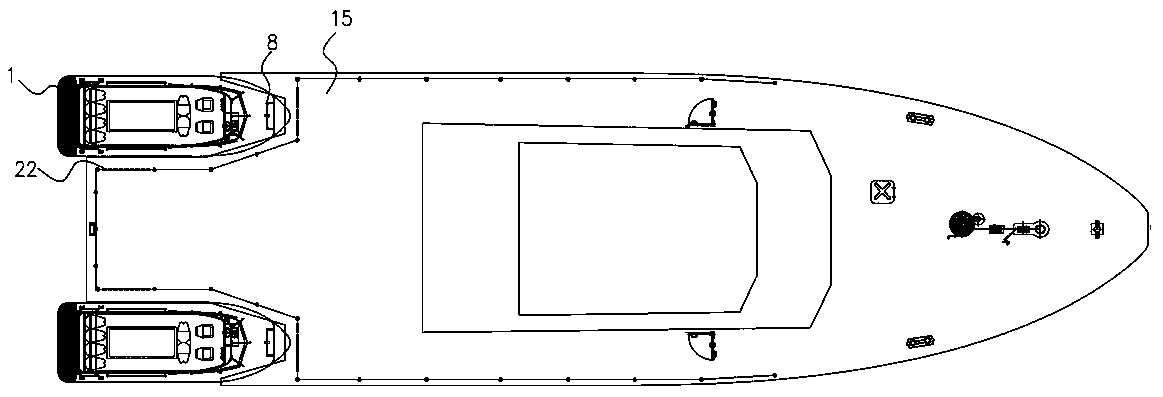

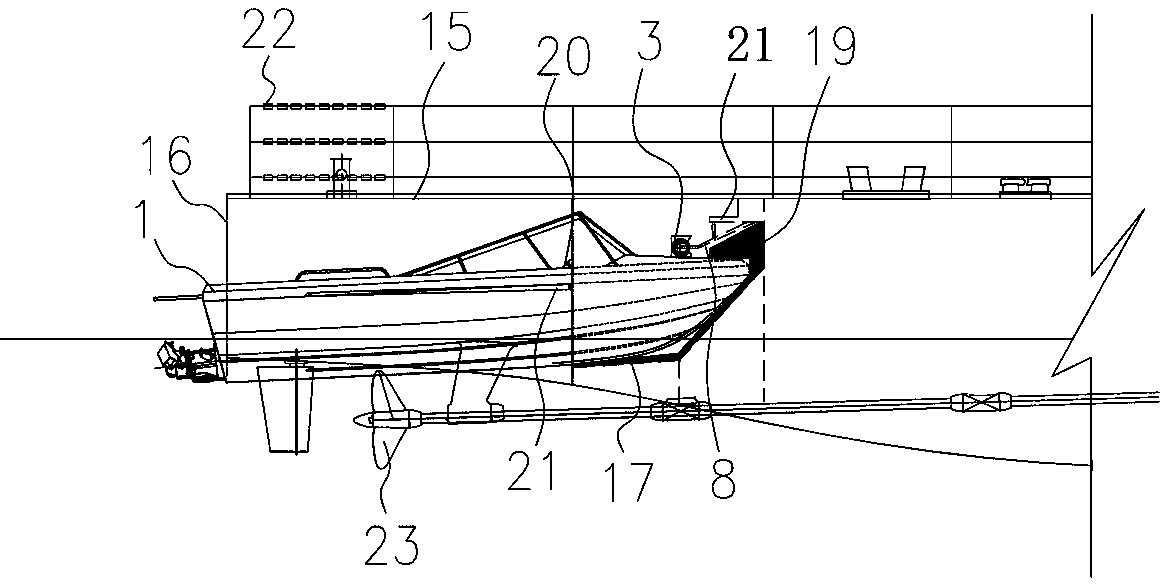

[0017] A carrying structure for a working boat, such as Figure 1 to Figure 8 As shown, it includes a berth area 2 for accommodating the working boat 1 arranged at the stern and adapted to the shape of the working boat 1, and a catch buckle 3 is provided at the bow of the working boat 1; the catch buckle 3 includes installation On the buckle mounting seat 4 at the bow of the working boat 1, a groove 5 is provided on the side of the buckle mounting seat 4 facing the stern, and a groove 5 that runs through the buckle mounting seat 4 and surrounds the groove 5 is also provided on this surface. The arc-shaped through hole is provided with a dead bolt return spring 6 and a dead bolt 7 that can slide relative to the arc-shaped through hole. One end of the dead bolt 7 is offset against one end of the dead bolt return spring 6, and the dead bolt When the back-moving spring 6 was in the natural state, the end of the dead bolt 7 that was not in contact with the dead bolt back-moving spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com