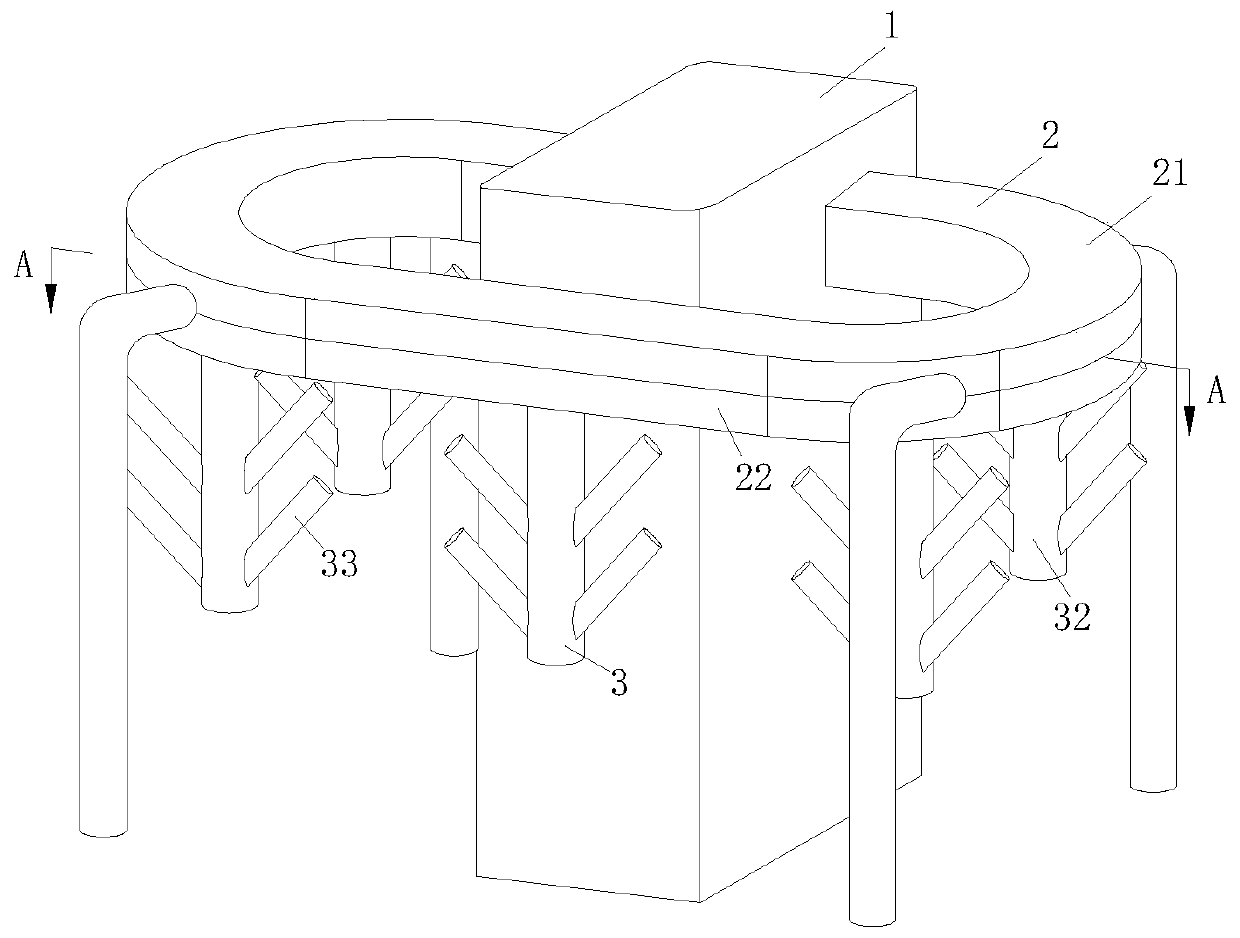

Shot peening machine

A shot peening machine and shot peening technology, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problems of poor shot peening effect of tubular objects, so as to improve the shot peening effect and improve practicability , The effect of reducing the cost of shot peening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

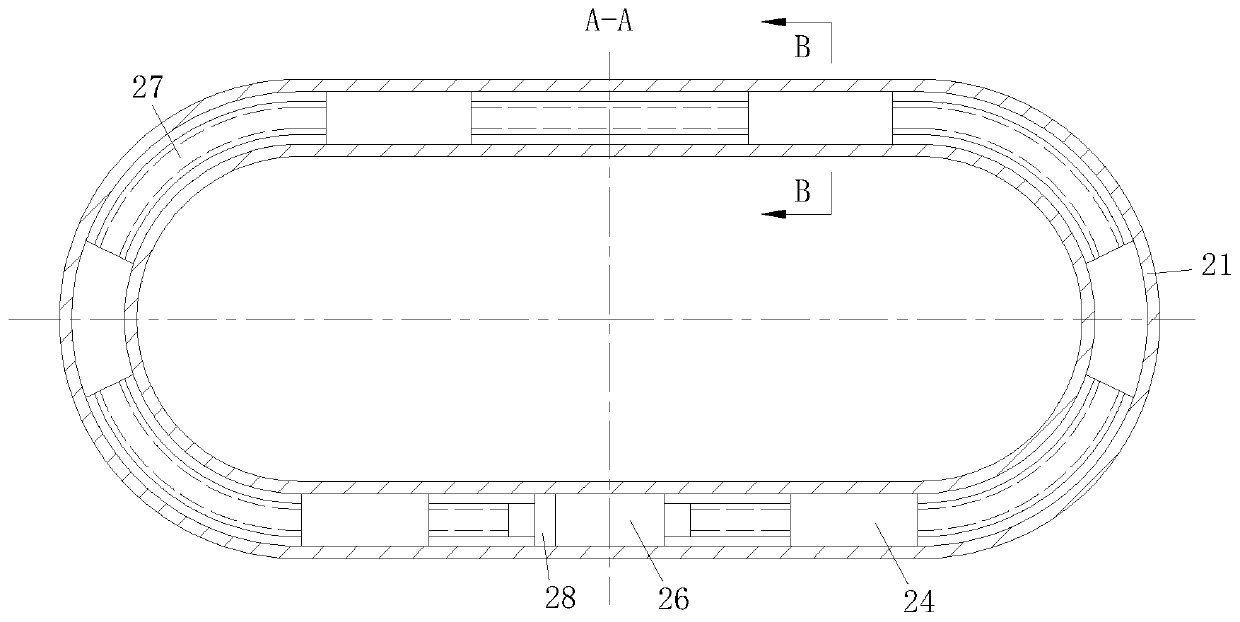

Method used

Image

Examples

Embodiment approach

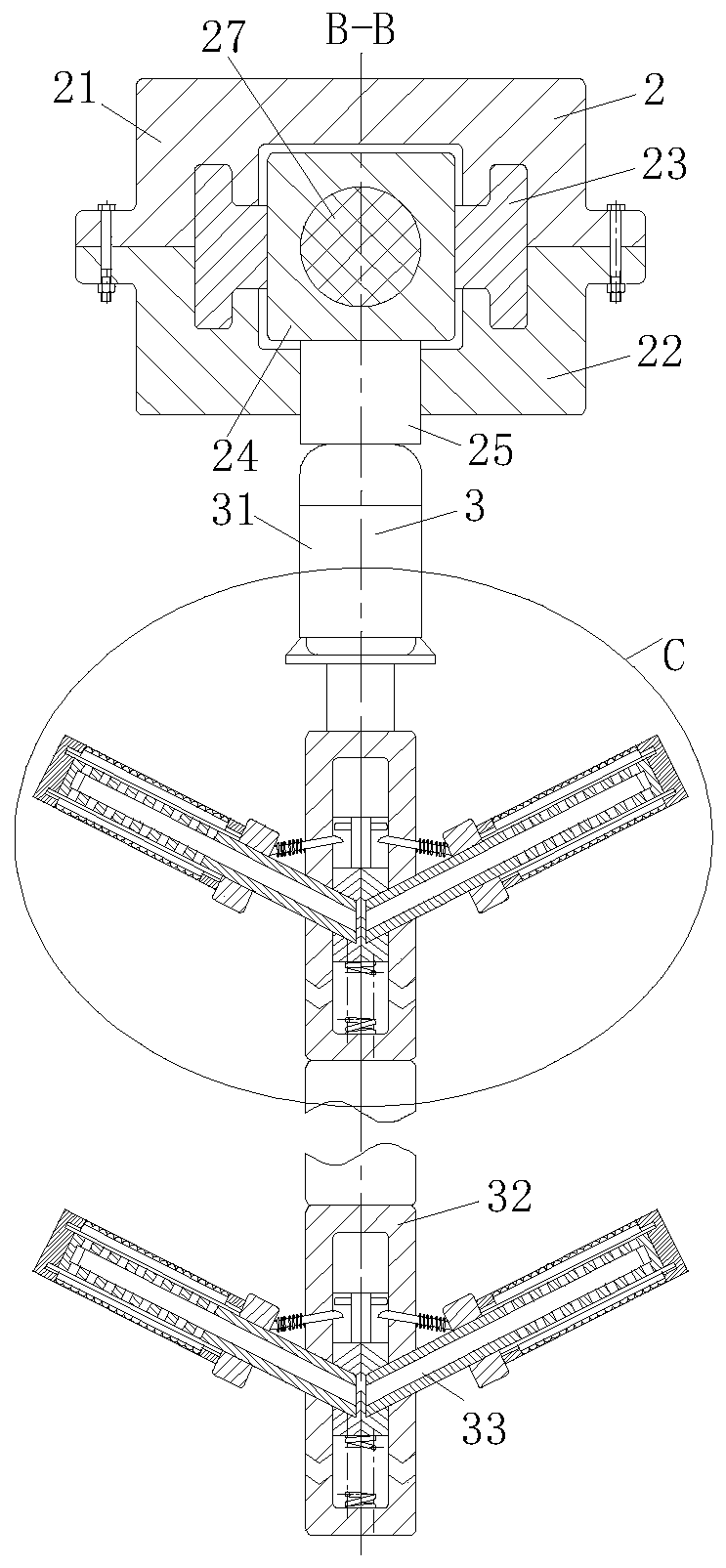

[0035] As a specific embodiment of the present invention, a No. 1 channel 331 and a group of No. 1 holes 332 are opened on the No. 1 rod 33 , and each No. 1 hole 332 communicates with the No. 1 channel 331 ; the sleeve 53 There is a No. 1 slot on the top, and the No. 1 slot is connected with a push plate 55 by a spring, and a group of protrusions 56 are arranged on the end surface of the push plate 55 close to the tubular object; the air flow generated by the movement of the push block 51 passes through the No. 1 channel 331 and a group of No. 1 holes 332 act on the push plate 55 to prevent the tubular object from falling off from the sleeve 53; by setting the push plate 55, a group of protrusions 56 on the push plate 55 are used to increase the distance between the inner wall of the tubular object and the tubular object. friction, which eliminates the possibility of the tubular object breaking away from the sleeve 53, reduces the subsequent processing of the tubular object aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com