Silent food processor

A food processing machine and silent technology, applied in kitchen utensils, home utensils, applications, etc., can solve the problems of limited vibration energy absorption, easy hardening of silicone parts, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

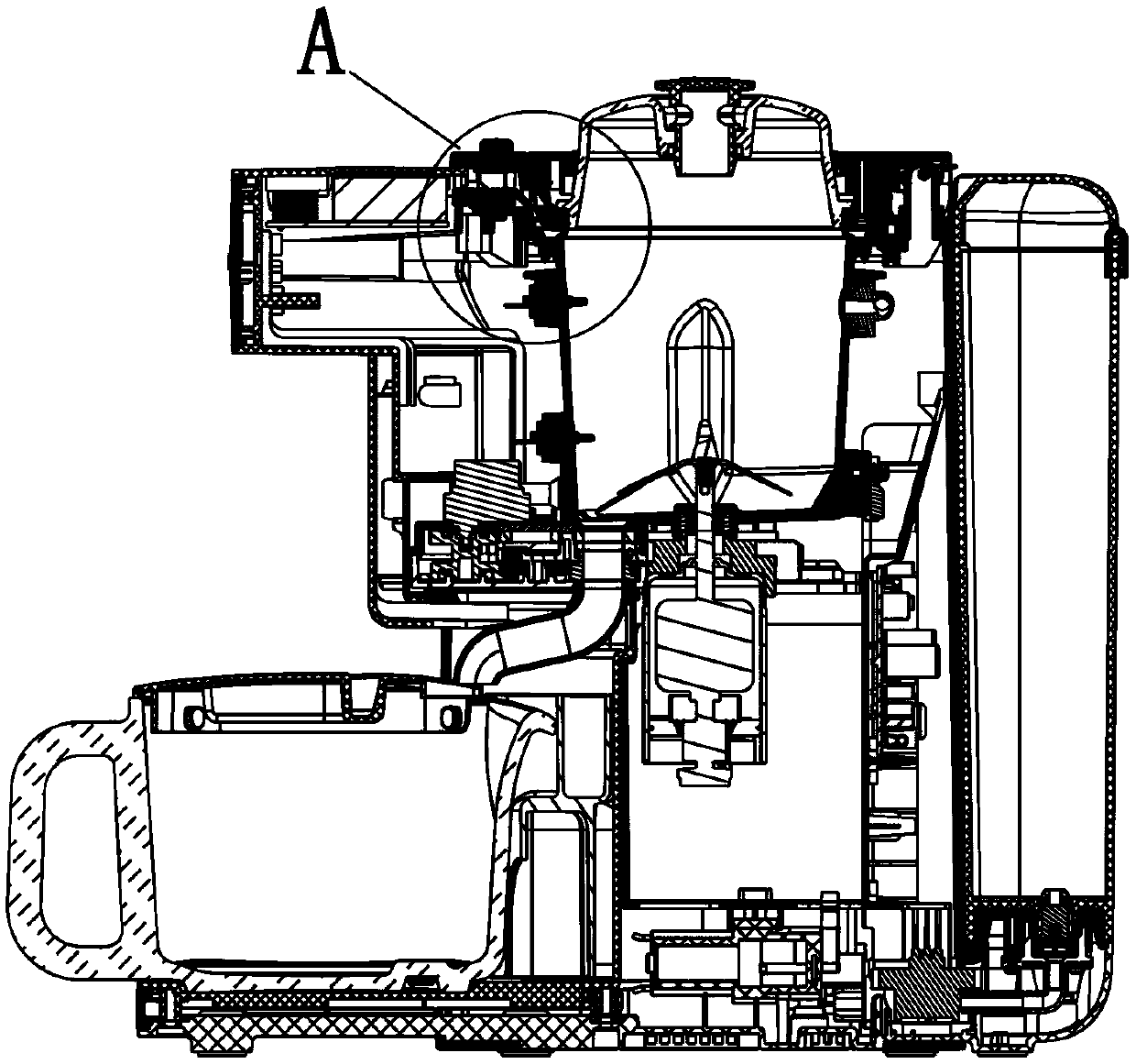

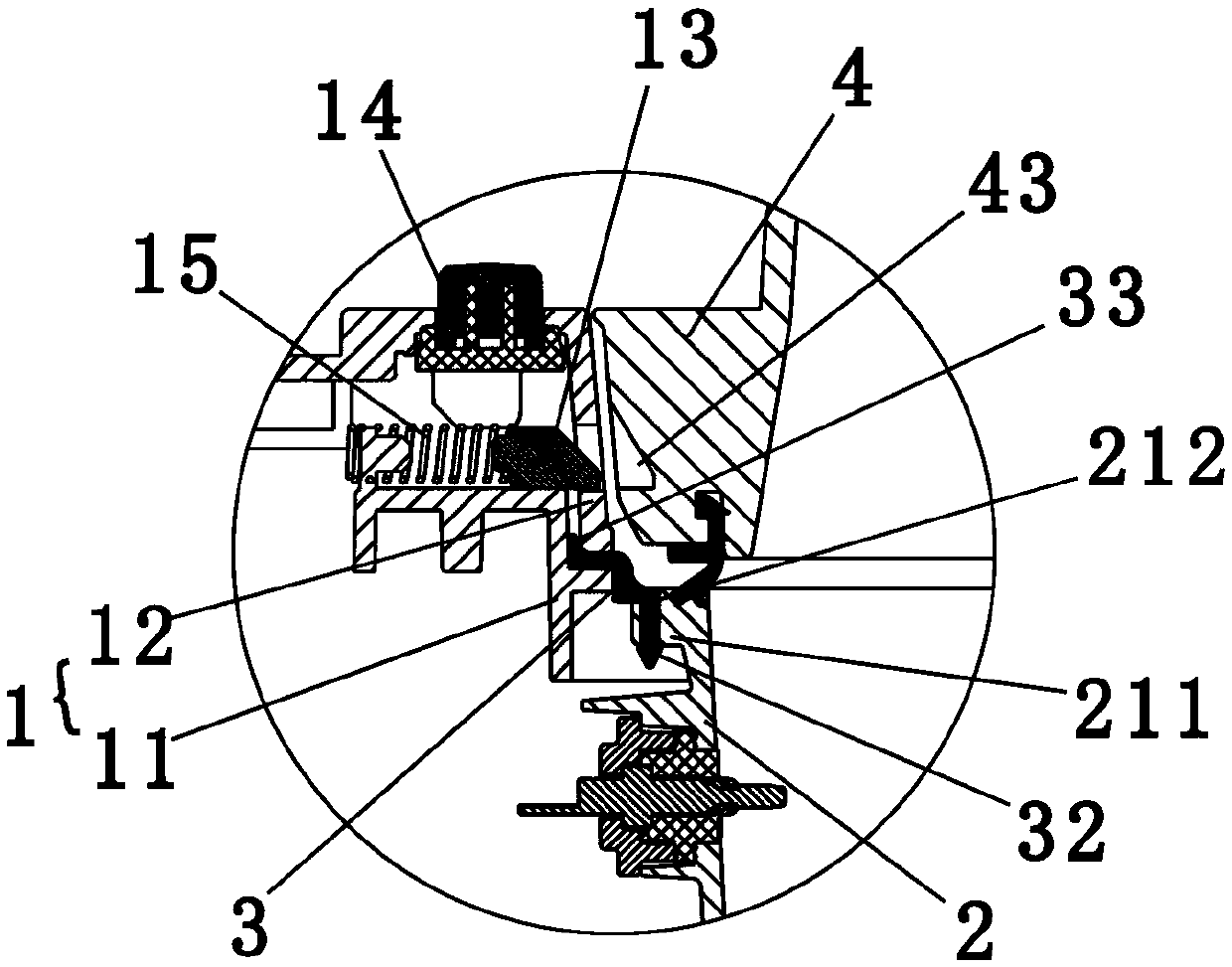

[0038] Such as Figures 1 to 8 Shown is a schematic structural diagram of the first embodiment of the present invention. A food processor, comprising a housing 1 and a cup assembly 2 installed in the housing 1, there is an annular installation gap (not marked in the figure) between the housing 1 and the cup assembly 2, so that the cup The body assembly 2 is not in contact with the housing 1, and flexible connectors 3 are provided at the installation gap to connect the housing 1 and the cup assembly 2 as a whole, wherein one end of the connector 3 is fixed to the housing 1 The other end is fixed on the cup assembly 2, so that the mouth of the cup assembly 2 can float relative to the housing 1.

[0039] In this embodiment, the connecting piece 3 is a connecting ring of silica gel arranged around the cup opening 21 of the cup assembly, the inner ring of the connecting ring is fixed on the cup opening 21, and the outer ring of the connecting ring is fixed on the housing 1 , so t...

Embodiment 2

[0054] Such as Figure 9 Shown is a schematic structural diagram of the second embodiment of the present invention. The difference between this embodiment and the first embodiment lies in that in this embodiment, the connecting ring has a tightening portion 36 that hugs the outer wall of the cup assembly 2 , and the tightening portion 36 forms the inner ring of the connecting ring. At the same time, an outward flange 211 is provided at the mouth of the cup, and a step 361 for supporting the flange 211 is provided on the gripping portion 36 , so that the inner ring of the connecting ring is fixed on the cup assembly 2 . Simultaneously, the outer ring of the connecting ring is provided with an undercut 37, the upper casing 12 and the fixed bracket 11 are fixed by the screw b, and when the upper casing 12 and the fixed bracket 11 are fixed, the outer ring of the connecting ring is clamped so that the undercut 37 is closely attached to the fixed bracket 11, so that the outer ring...

Embodiment 3

[0057] Such as Figure 10 , Figure 11 Shown is a schematic structural view of the third embodiment of the present invention. The difference between the present embodiment and the second embodiment is that in this embodiment, there is no fixed bracket, the casing through hole 100 is provided on the side wall of the casing 1, and the outer ring of the connecting ring is provided with a buckle plug 38. The plug 38 is inserted into the through hole 100 of the housing and snapped onto the outer edge of the through hole 100 of the housing, so that the outer ring of the connecting ring is fixed on the housing 1 . At the same time, a clamp 6 for tightening the clamping portion 36 is provided on the outside of the clamping portion 36 .

[0058] The hoop 6 in this embodiment includes a left hoop 61 and a right hoop 62, and the left hoop 61 and the right hoop 62 are fixed by screws c, so as to tighten the holding part 36 on the outer wall of the cup assembly 2 .

[0059] This embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com