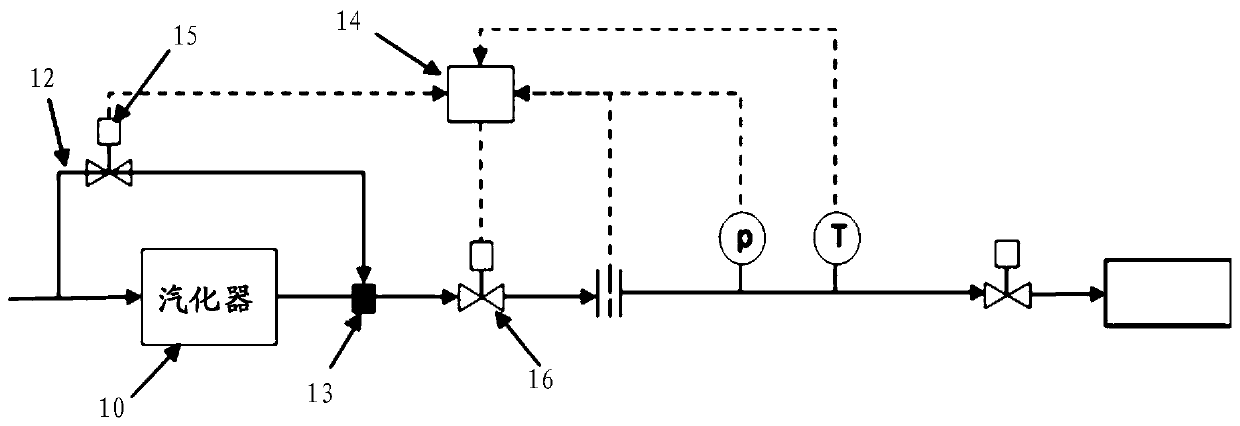

Fluid bypass method and system for controlling temperature of non-petroleum fuel

A non-petroleum, fuel-free technology, applied in the field of pressurized gas or liquid dispensing system, which can solve the problems of large footprint of temperature control unit, insufficient cooling capacity of refrigeration system, high labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

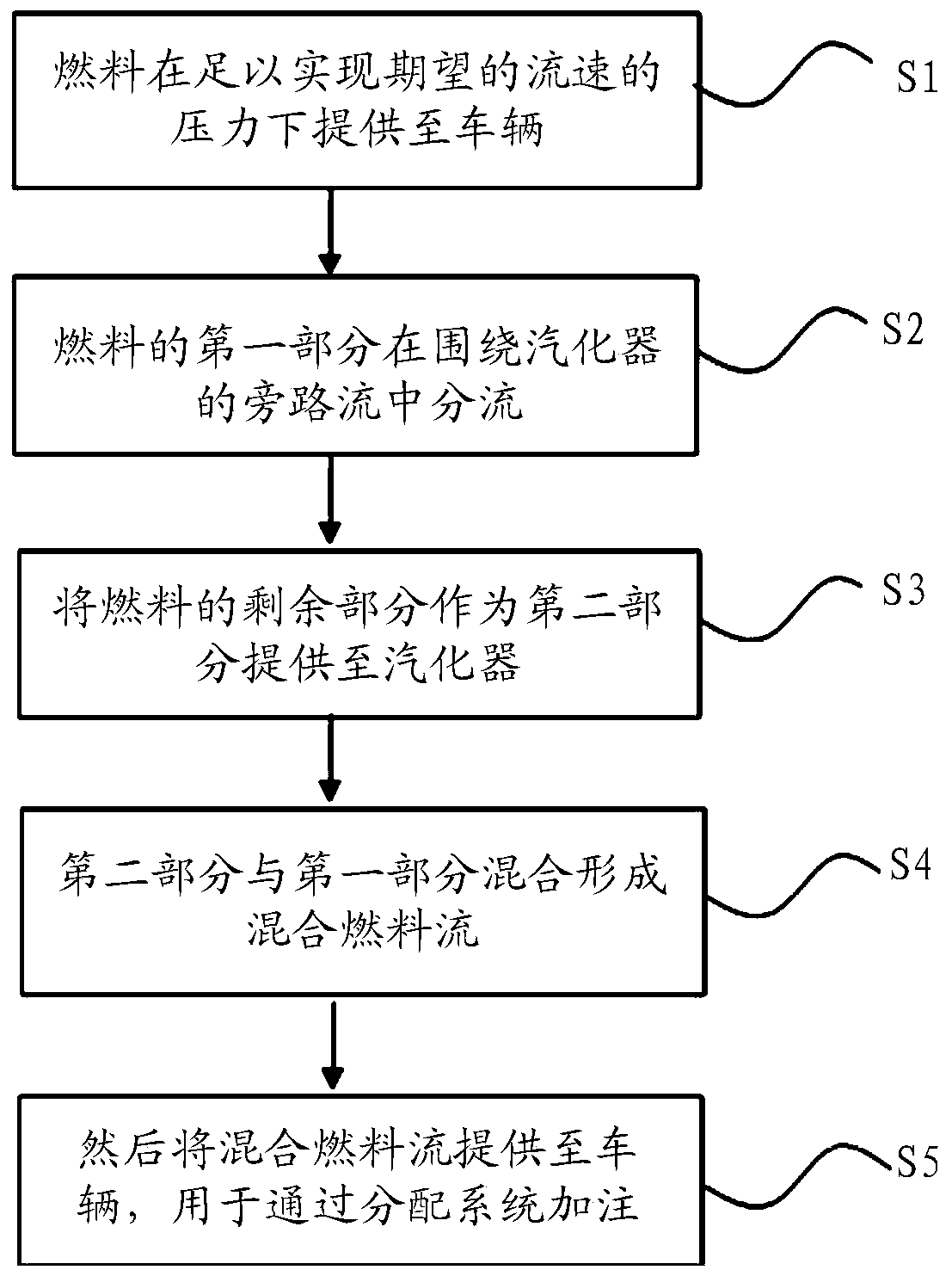

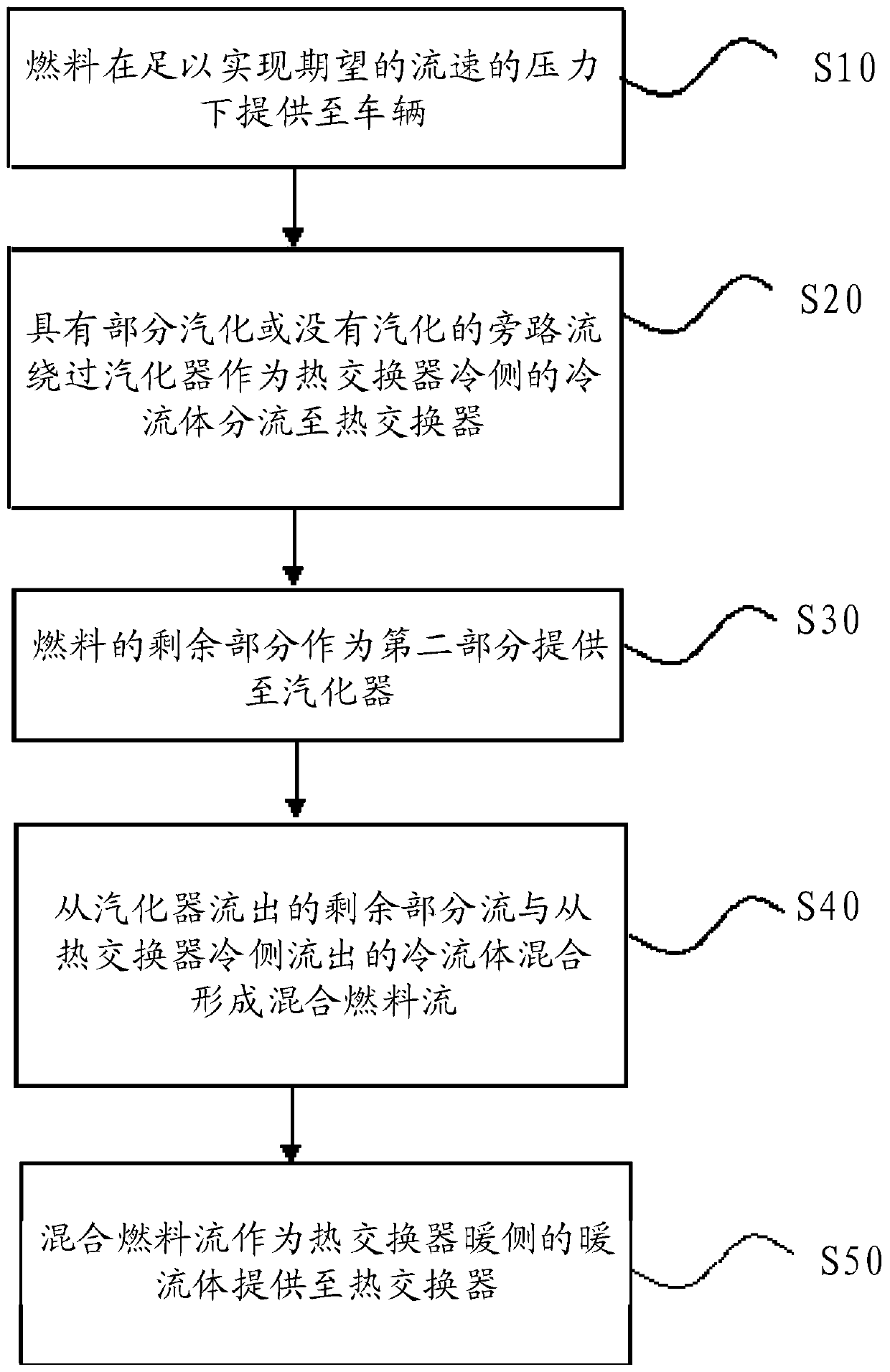

Method used

Image

Examples

Embodiment 1

[0085] Hydrogen at 450 bar and 20K (-253°C) was used to fill a substantially empty vehicle tank at 95 bar. In this case, 30% of the fuel stream is split as a bypass stream and enters the heat exchanger, after which the bypass stream has a temperature of -50°C. The remainder of the hydrogen fuel flow enters the vaporizer. The bypass flow through the heat exchanger is then mixed with the fuel flow through the carburetor to form a mixed fuel flow, where the temperature of the mixed fuel flow is -1°C, which is a temperature for flow meters, controllers and other components in the distributor. Comfortable to avoid thermal shock and thermal stress due to temperature fluctuations.

Embodiment 2

[0087] Hydrogen at 450bar and 20K (-253°C) is used to fill an essentially empty vehicle tank at 195bar, where 29% of the fuel flow is diverted as a bypass stream and enters a heat exchanger where, after passing through the heat exchanger, the bypass The temperature of the flow is -50°C. The remainder of the hydrogen fuel flow enters the vaporizer. The bypass flow through the heat exchanger is then mixed with the remainder of the fuel flow through the carburetor to form a mixed fuel flow, where the temperature of the mixed fuel flow is 0°C, which is critical for flow meters, controllers and other components in the distributor is comfortable.

Embodiment 3

[0089]Hydrogen at 450bar and 20K (-253°C) is used to fill an essentially empty vehicle tank at 295bar, where 27% of the fuel flow is split as a bypass stream and enters a heat exchanger where, after passing through the heat exchanger, the bypass The temperature of the road flow is -50°C. The remainder of the hydrogen fuel flow enters the vaporizer. The bypass flow passing through the heat exchanger is then mixed with the remainder of the hydrogen fuel flow flowing through the vaporizer to form a mixed fuel flow, and the temperature of the mixed fuel flow is 1°C, which is a temperature for flow meters, controllers and other components in the distributor. Components are comfortable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com