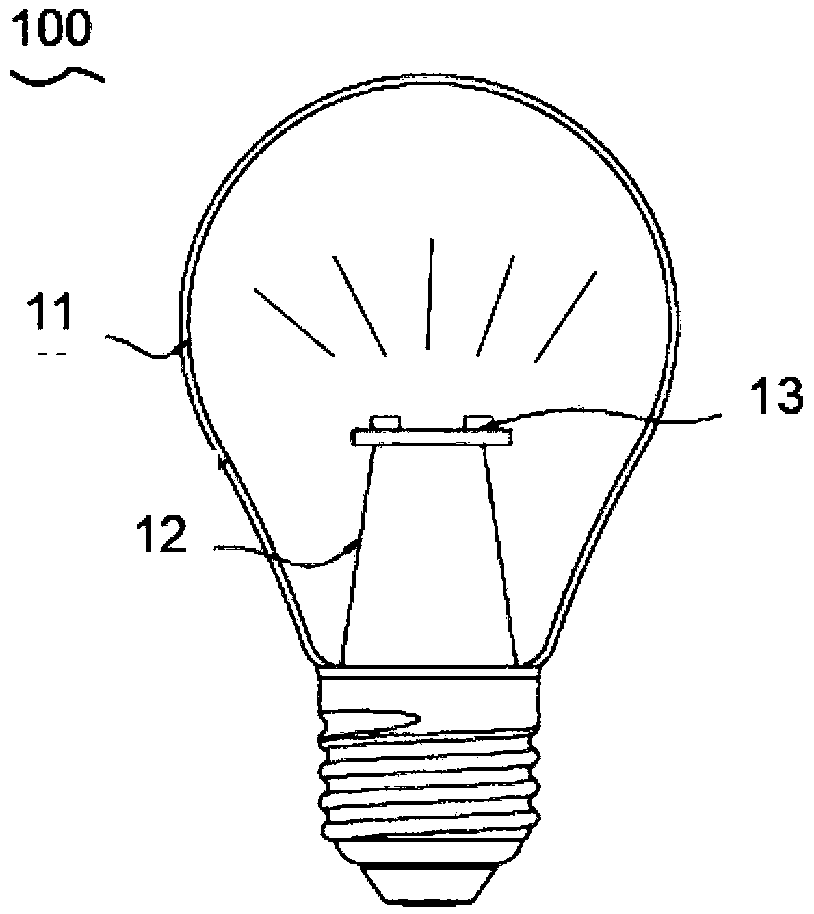

Fluorescent nanomaterial-polymer complex, preparation method of wavelength conversion element, and light-emitting device

A technology of fluorescent nanomaterials and wavelength conversion elements, applied in the field of fluorescent nanomaterials, can solve problems such as poor stability of fluorescent nanomaterials, and achieve the effects of good light stability, simple molding and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

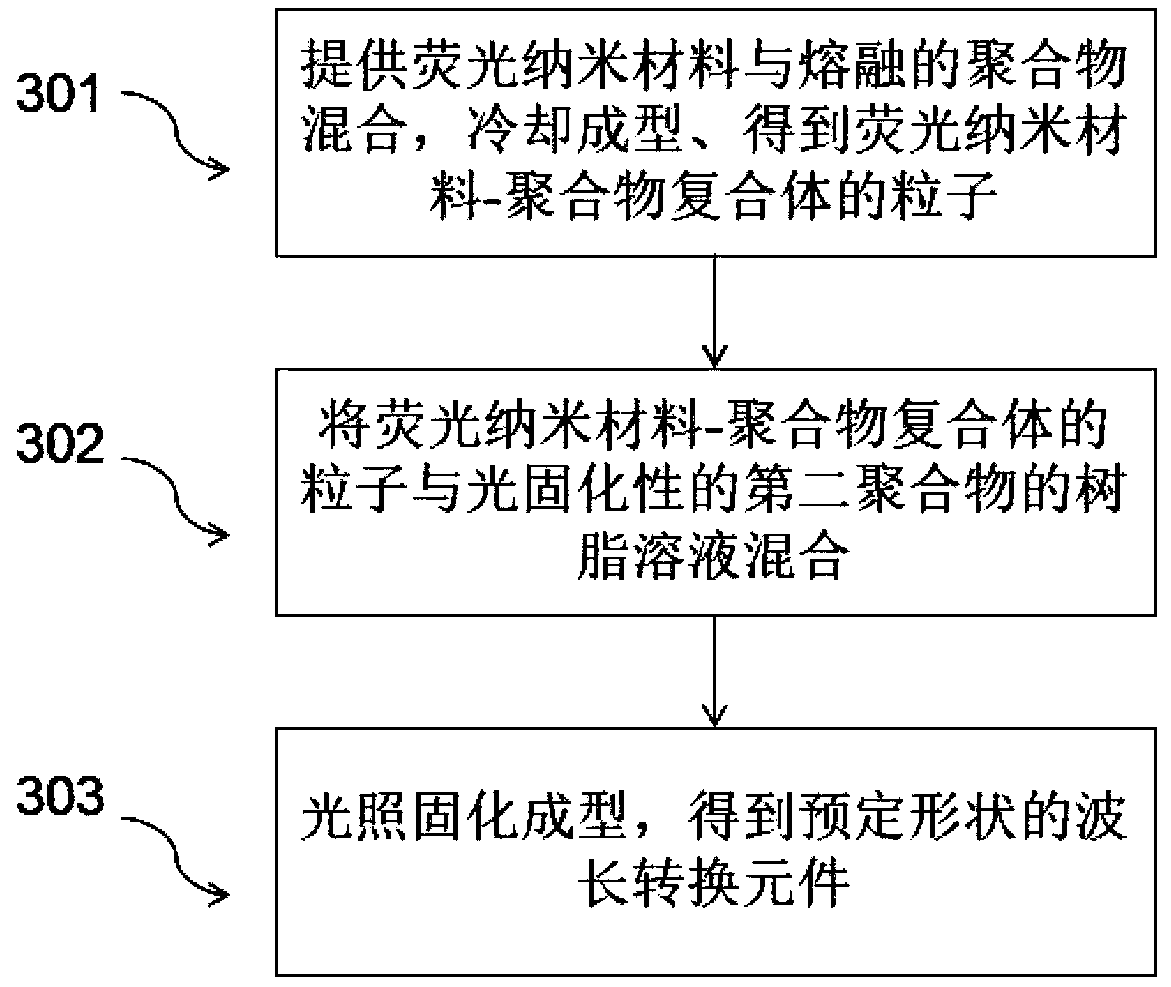

[0033] According to some exemplary embodiments of the present application, the method for preparing a fluorescent nanomaterial-polymer composite includes: providing a precursor, the precursor including a fluorescent nanomaterial and a polymer; temperature, allowing the precursors to mix, followed by a cooling step.

[0034] Fluorescent nanomaterials refer to materials that can emit light of another wavelength after receiving light of a certain wavelength. In the exemplary embodiment of the present application, the substance that can be used as the fluorescent nanomaterial is selected from at least one of nanoclusters, quantum dots, nanorods, and nanodisks, but is not limited thereto. In the present application, the emission peak width at half maximum of the fluorescent nanomaterial is preferably less than 60nm, and the excitation light can be purple light, blue-violet light or blue light and the like.

[0035] In this application, nanoclusters refer to relatively stable micro...

preparation Embodiment 1

[0095] Preparation Example 1: Preparation of InP / ZnS Quantum Dots

[0096] 0.4 mmol indium acetate, 1.2 mmol palmitic acid, and 10 mL trioctylamine were placed in a reactor and heated at 120°C under vacuum. After 1 hour, the atmosphere in the reactor was changed to nitrogen. After heating the reactor to 280° C., 0.2 mmol of tris(trimethylsilyl)phosphine was quickly injected thereinto, and the mixture was allowed to react. After the reaction solution was rapidly cooled to room temperature (24° C.), acetone was added thereto, and the InP core precipitate obtained by centrifuging the mixture was dispersed in toluene.

[0097] 0.9 mmol of zinc acetate, 1.8 mmol of oleic acid, and 10 mL of trioctylamine were placed in the reactor, followed by vacuum treatment at 120° C. for 10 minutes. The atmosphere in the reaction flask was replaced with nitrogen, and then heated to 280°C. A toluene solution according to the above InP core was added thereto within 10 seconds, 2.0 mmol of S-TOP...

Embodiment 1

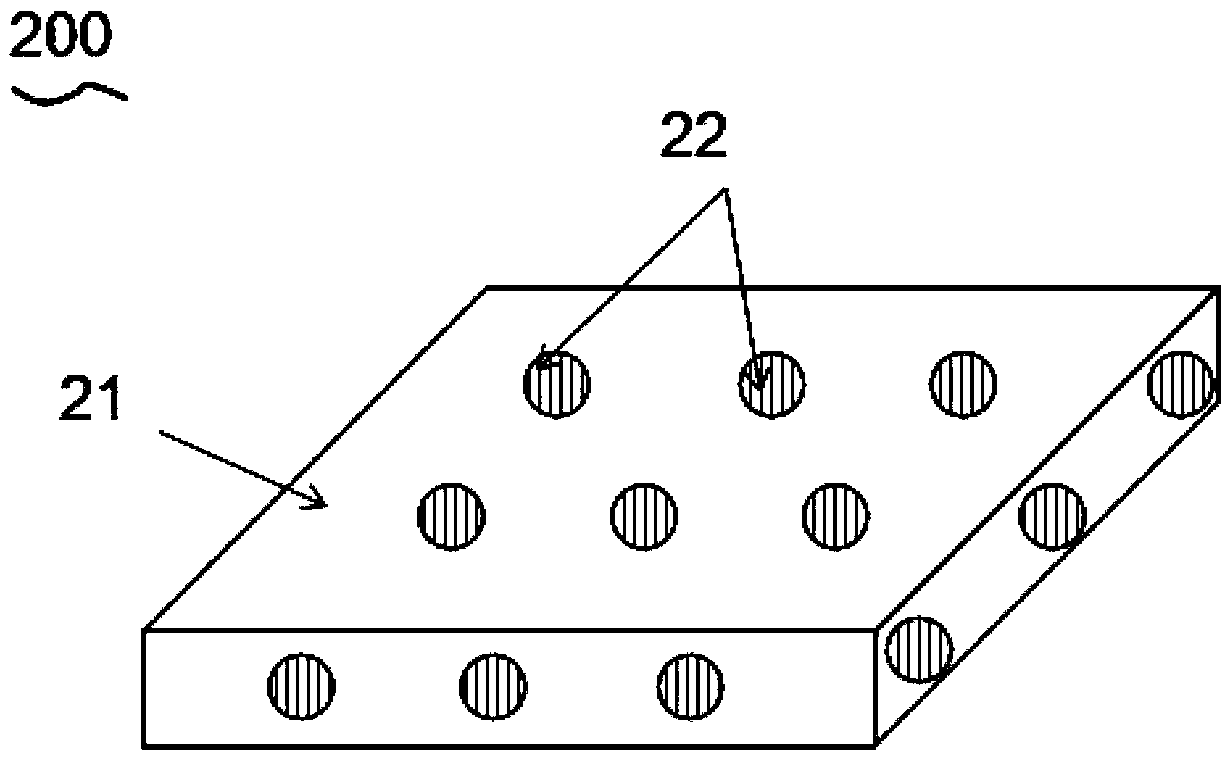

[0099] Example 1: Preparation of wavelength conversion film

[0100] Take an appropriate amount of InP / ZnS quantum dot toluene solution (InP / ZnS quantum dot is about 0.5g) in Preparation Example 1, 1g of white oil, and 500g of polypropylene (melting point is about 230°C) in a glass vessel, at 240°C Stirring and mixing, during the stirring process, the toluene is removed, and the InP / ZnS quantum dots are uniformly dispersed in the molten polypropylene, in the air, and a wavelength conversion film with a thickness of about 200 microns is prepared by tape casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com