Method for producing copper-infiltrated valve seat ring

A valve seat ring, copper infiltration technology, applied in the direction of lift valve, valve device, machine/engine, etc., can solve problems such as inaccuracy, and achieve the effect of optimizing immersion, saving time, and good separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

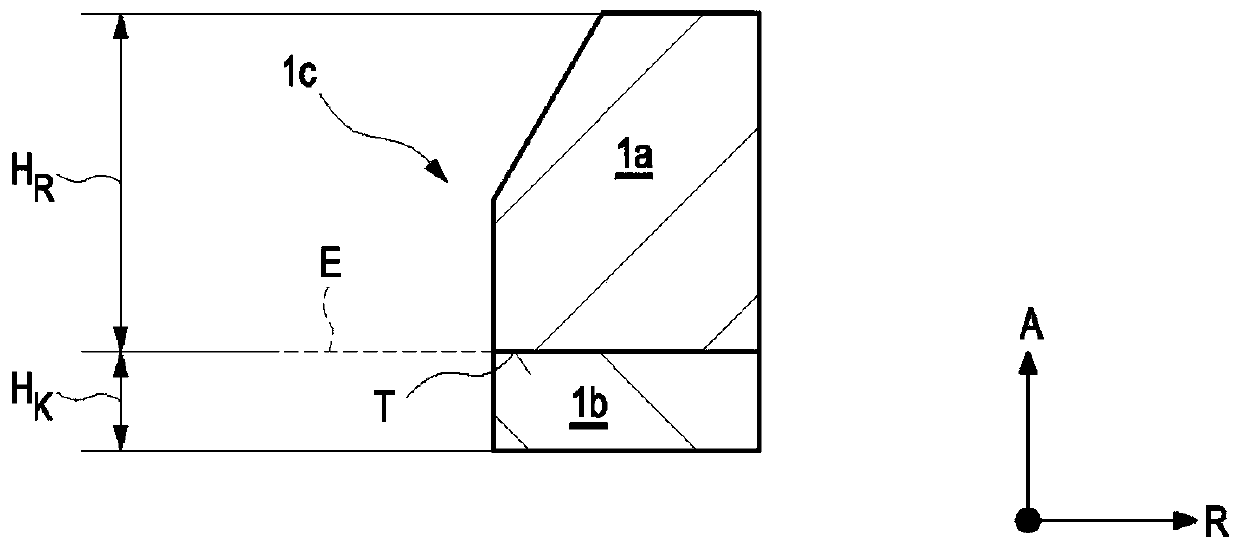

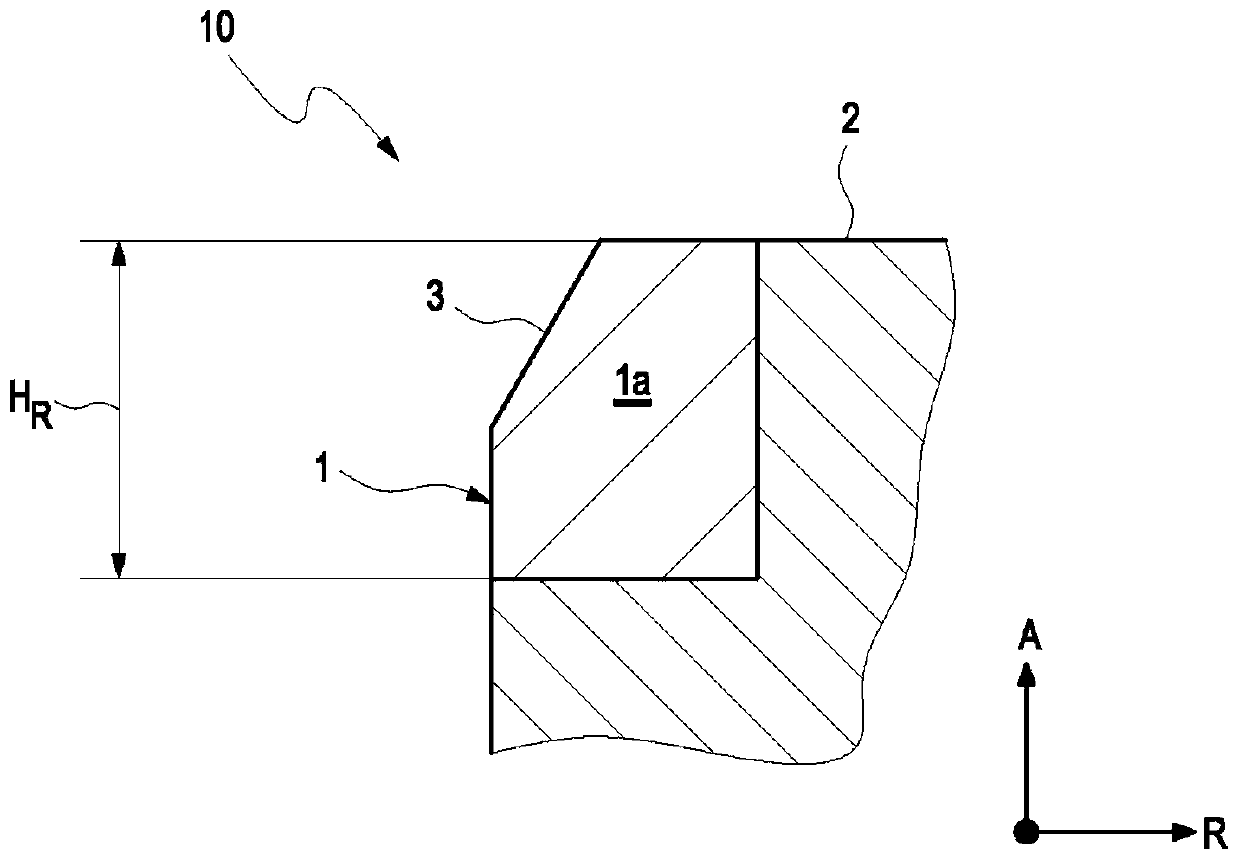

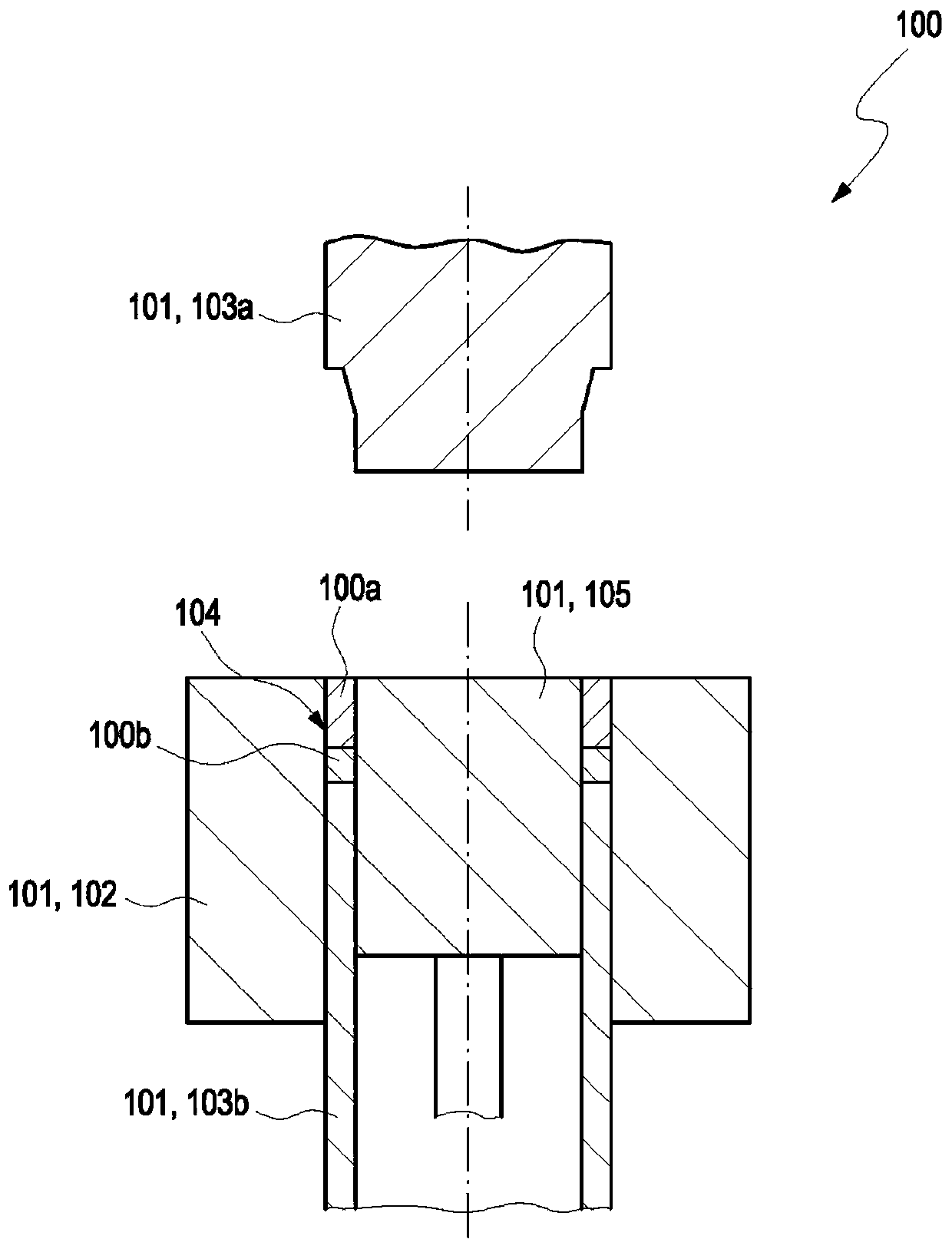

[0034] The following will be based on Figure 1 to Figure 3 The method according to the invention is described in an exemplary manner:

[0035]To carry out the method, the copper powder 100b and the functional material powder mixture 100a are introduced into the same connection chamber 104 . The copper powder 100b may thus be introduced before the functional material powder mixture 100a, or the functional material powder mixture 100a may be introduced before the copper powder 100b. Copper powder 100b and functional material powder mixture 100a may also be introduced simultaneously. The copper powder 100b and the functional material powder mixture 100a can thus be introduced into the cavity 104 in such a way that the copper powder 100b and the functional material powder mixture 100b do not substantially mix with each other during the introduction.

[0036] The functional material powder mixture may thus comprise metal powders based on iron, copper or cobalt, hard phases, carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com