Fuel injection system and method for injection

A technology of fuel injection system and fuel injection valve, which is applied in the direction of fuel injection device, charging system, combustion engine, etc. It can solve the problem of large distance between fuel injection valve and spark plug, reduce the temperature sudden change load, and improve the ignition angle. Sensitivity, less sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

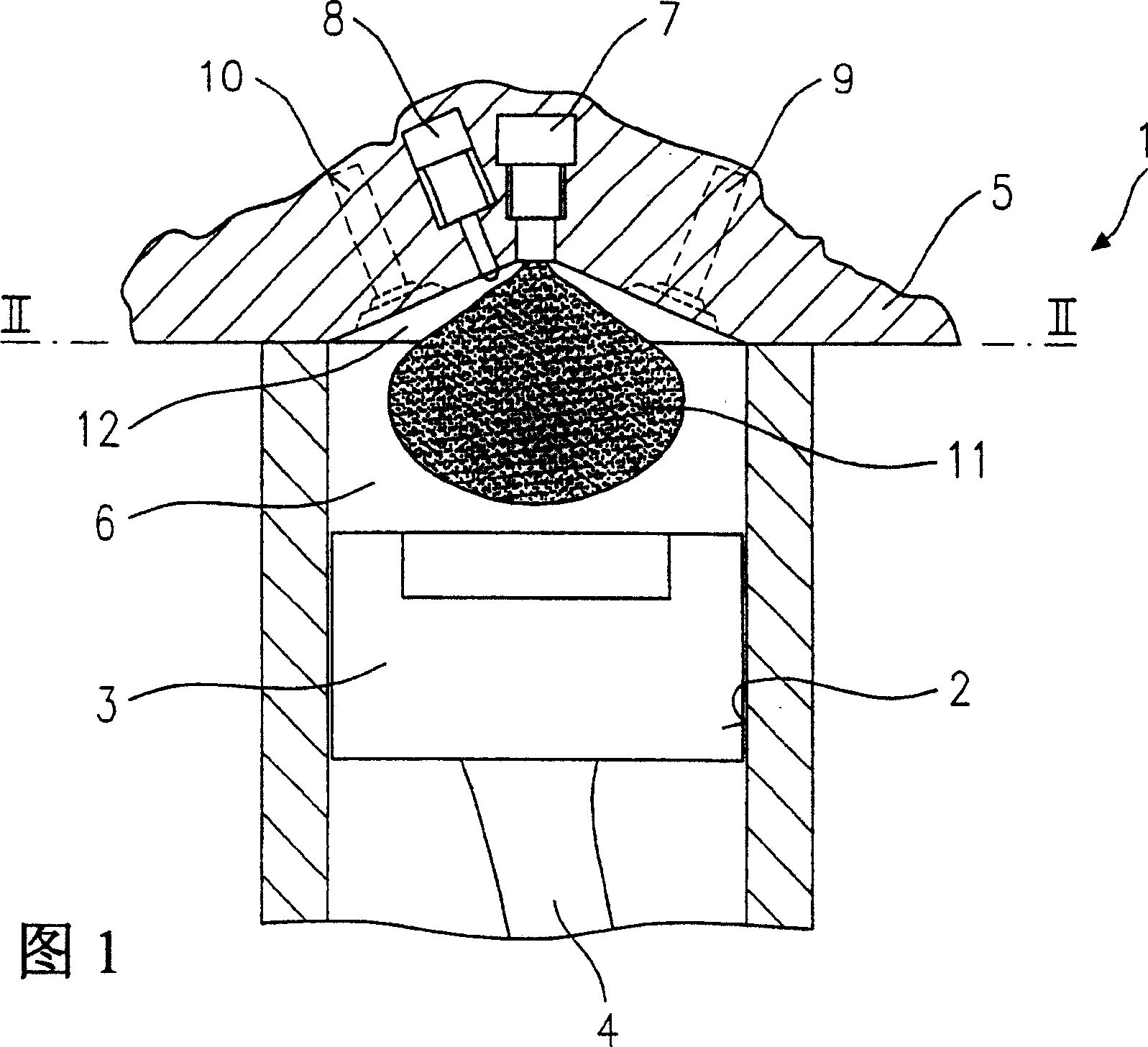

[0033] FIG. 1 shows an exemplary embodiment of a fuel injection system according to the invention in a partial sectional view.

[0034] The fuel injection system 1 comprises a cylinder block with a cylinder wall 2 on which a piston 3 is guided. The piston 3 runs up and down on the cylinder wall 2 via a connecting rod 4 . The cylinder wall 2 is closed at the end by a cylinder head 5 . Cylinder wall 2, piston 3 and cylinder head 5 enclose a combustion chamber 6.

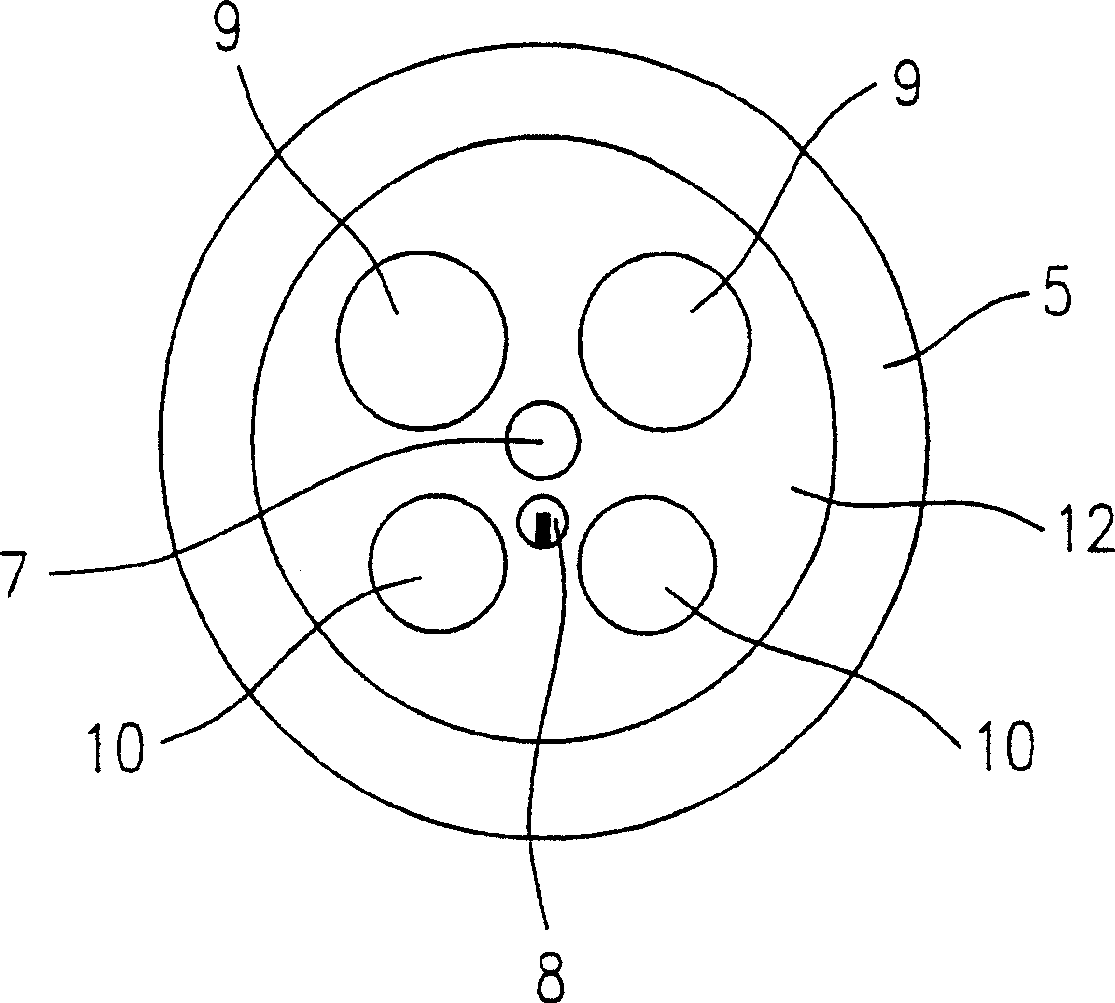

[0035] A fuel injector 7 is preferably arranged centrally in the cylinder head 5 . A spark plug 8 is inserted into a hole in the cylinder head 5 at a lateral offset. In addition, there is at least one intake valve 9 and at least one exhaust valve 10 . figure 2 The configuration of fuel injection valve 7, spark plug 8, intake valve 9 and exhaust valve 10 is shown in detail in .

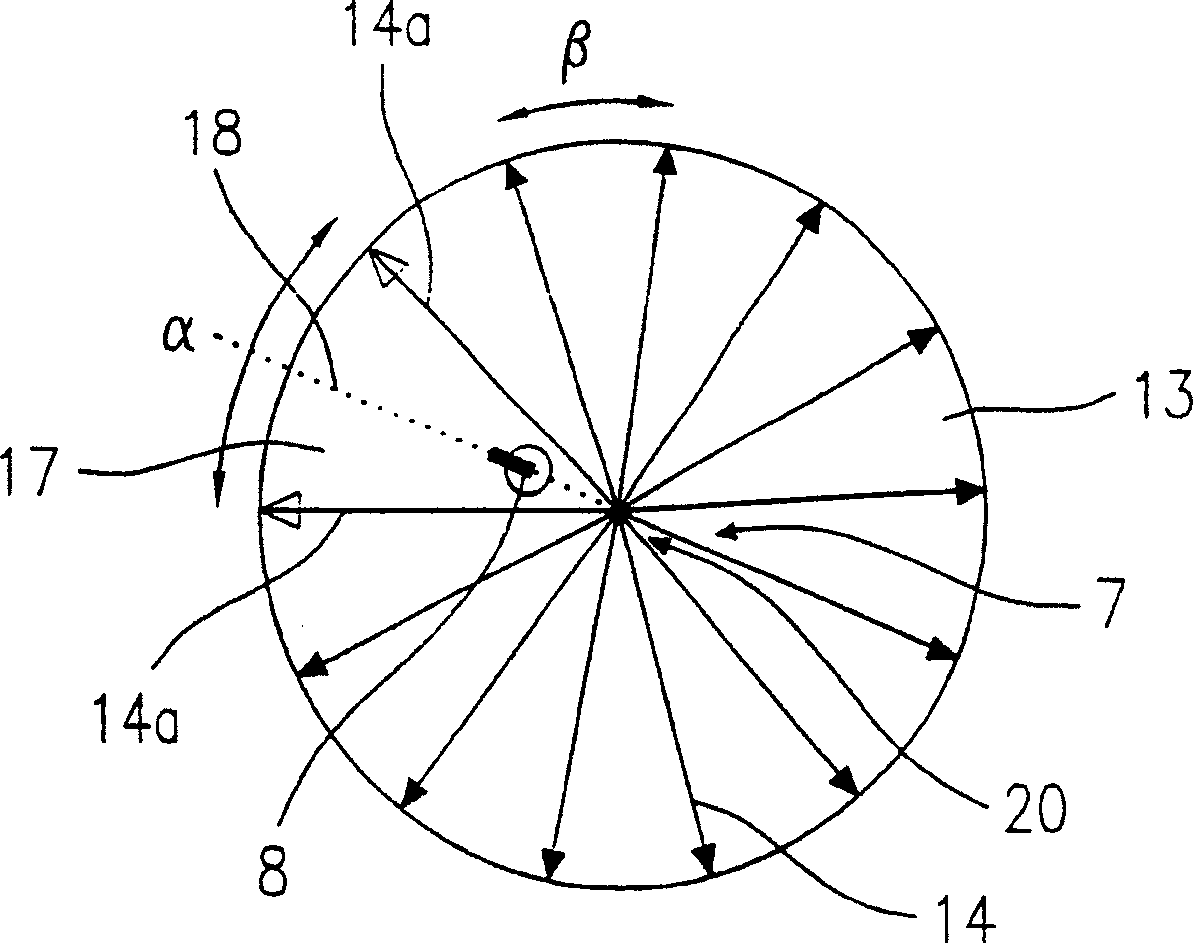

[0036] When the fuel injection system 1 is in a working state, a conical fuel oil beam is sprayed into the combustion chamber 6 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com