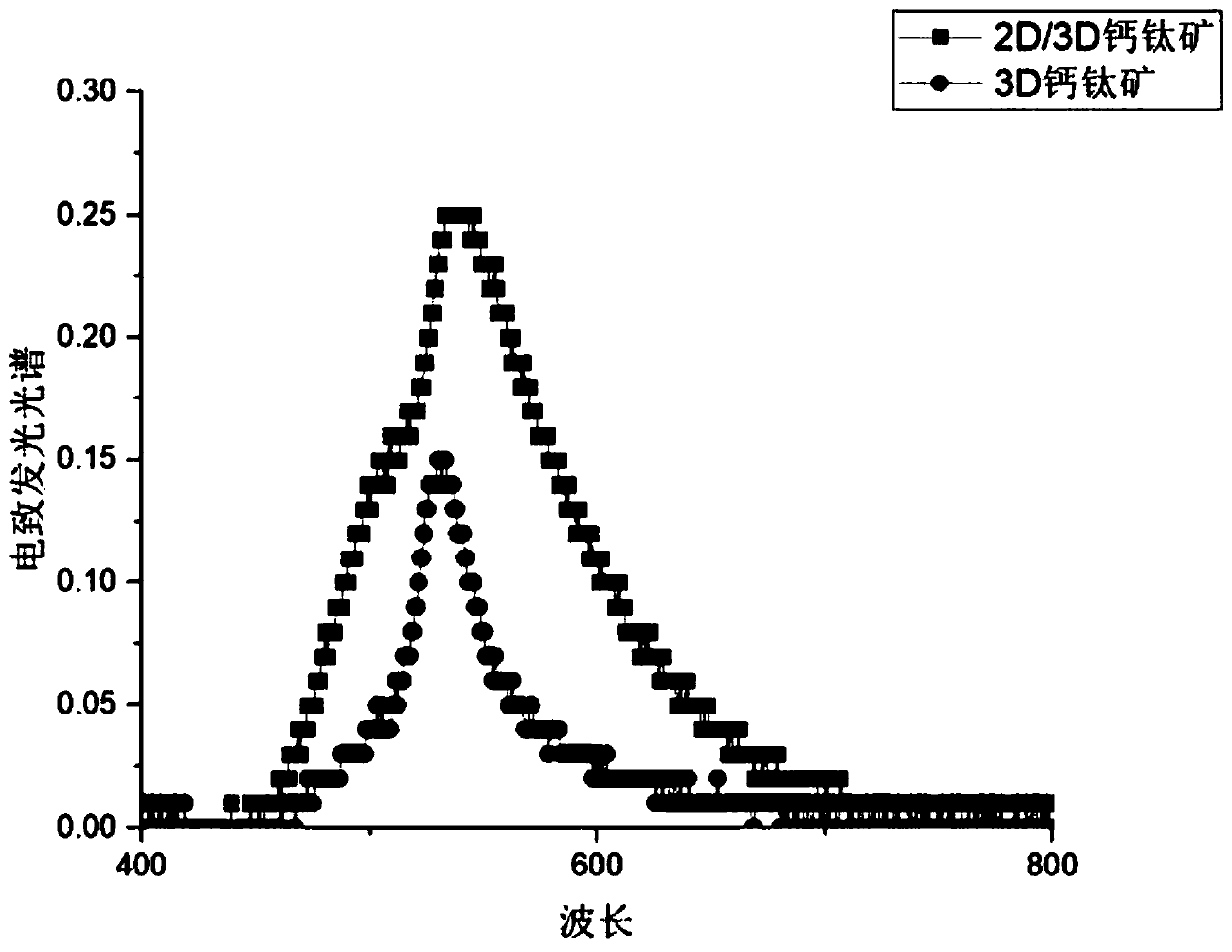

Perovskite 2D/3D LED structure and preparation method thereof

A 3D LED and perovskite technology, applied in the field of preparation of new electronic components, can solve the problems of inability to protect materials from moisture and oxygen erosion, and achieve improved water stability, high turn-on voltage, and hole extraction promotion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0026] A perovskite 2D / 3D LED structure of the present invention includes a multi-layer structure, which is a hole transport layer, a light-emitting layer, an electron transport layer and an electrode from bottom to top. The structure is as follows figure 1 As shown, in this embodiment, the electrodes are gold electrodes.

[0027] A kind of preparation method of perovskite 2D / 3D LED structure of the present invention is as follows (wherein, relate to spin-coating process in each step, such as Figure 4 shown):

[0028] Step 1, cleaning the transparent conductive glass substrate, the substrate used is etched ITO glass

[0029] Using transparent and conductive ITO glass as the substrate, it is chemically cleaned. The cleaning steps are: first, the substrate is ultrasonically oscillated with detergent and deionized water for 10 minutes, and then deionized water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com