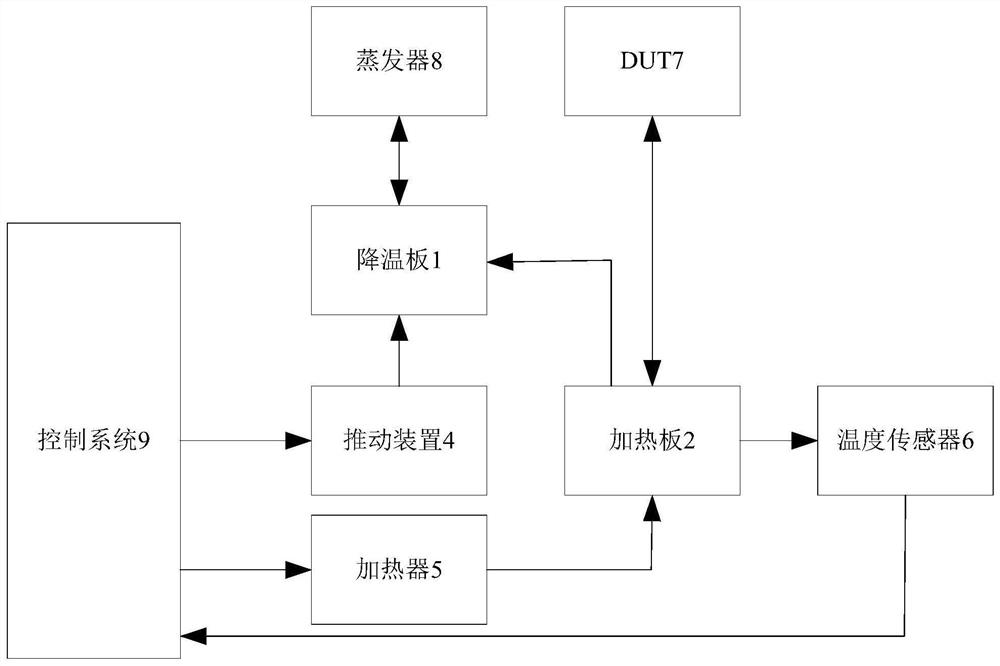

Temperature control system and method for controlling temperature of device under test

A technology for equipment under test and control system, applied in control/regulation system, temperature control, non-electric variable control, etc., can solve the problems of limited cooling capacity, affecting the working parameters of circuit boards, and difficult to strictly control the DUT, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

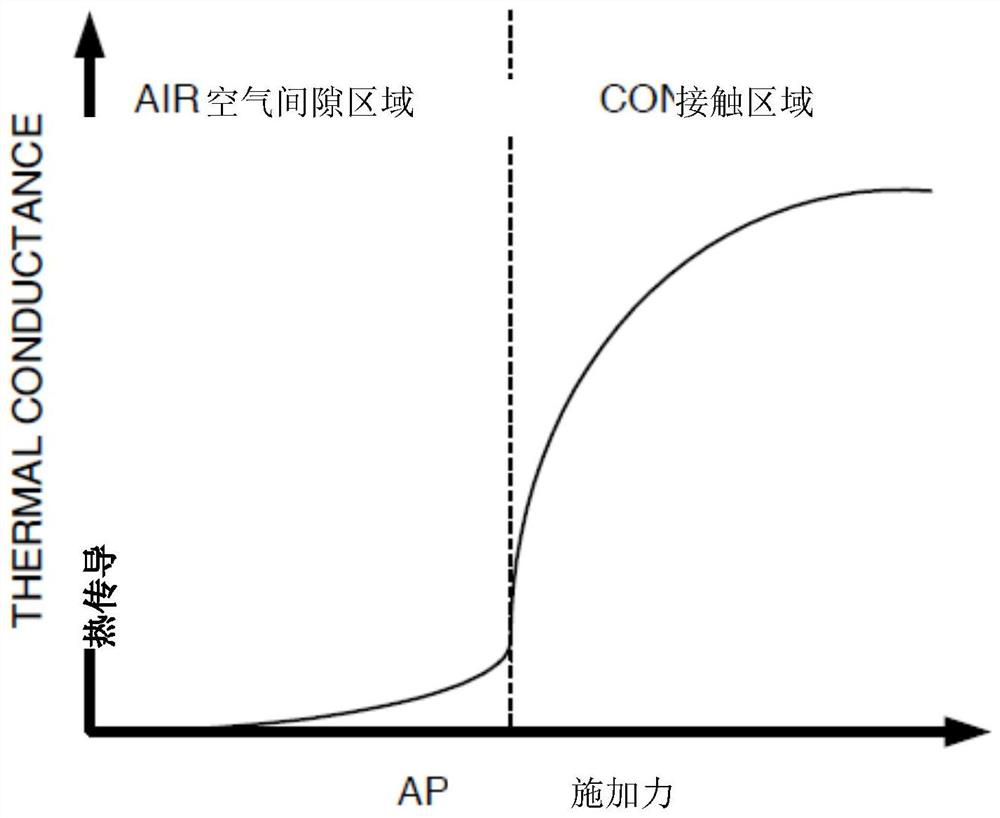

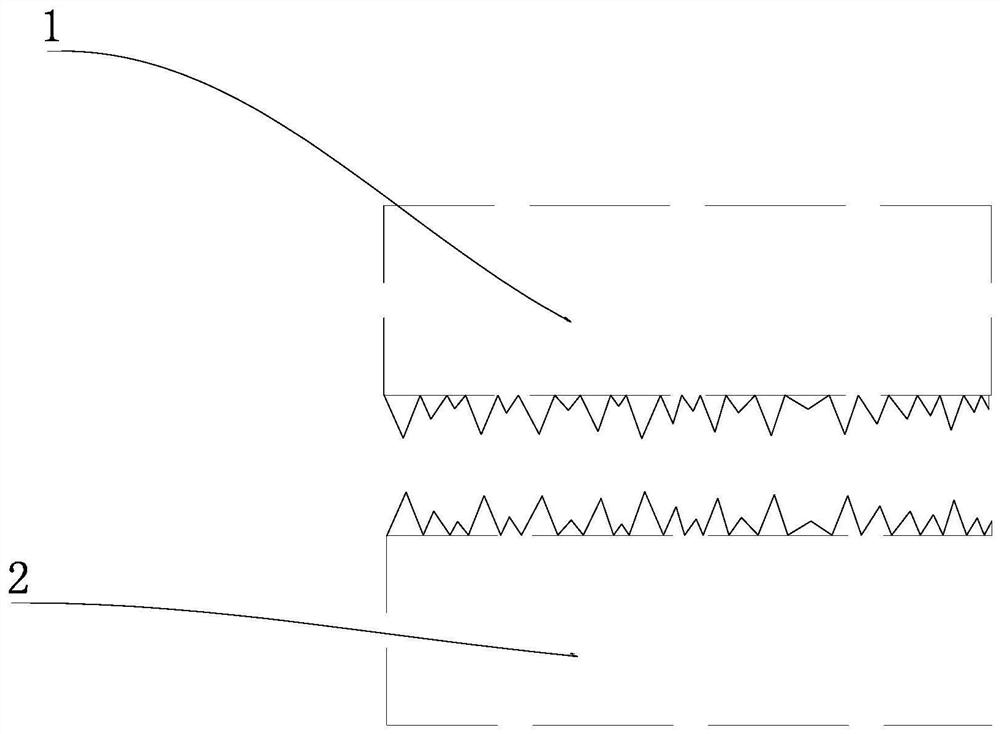

[0064] Example 2: see figure 2 , the relationship between heat conduction and force is characterized in two different regions, the first region on the left is the "air gap region", the second region on the right is the "contact region", in the air gap region, the force can always increase Until the bias spring is compressed into the first spring groove and the second spring groove, that is, the gap distance between the heating plate 2 and the cooling plate 1 is 0 at this time, and in the contact area, the heat conduction rate is determined by the cooling plate 1 to the heating plate 2 The heat absorbed by cooling plate 1 from heating plate 2 is determined by the temperature of cooling plate 1 and the heat conduction rate between cooling plate 1 and heating plate 2, please continue to refer to figure 2 , the left side is the heat conduction rate before the cooling plate 1 touches the heating plate 2. As the applied force F reaches a critical value, that is, the applied force>...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com