Suspension slurry and method for reactive bonding of silicon carbide ceramics

A technology of silicon carbide ceramics and suspension, which is applied in the field of ceramic connection, can solve the problems of unsatisfactory connection layer performance and uneven distribution of residual silicon, and achieve the effect of improving joint reliability, small stress concentration, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

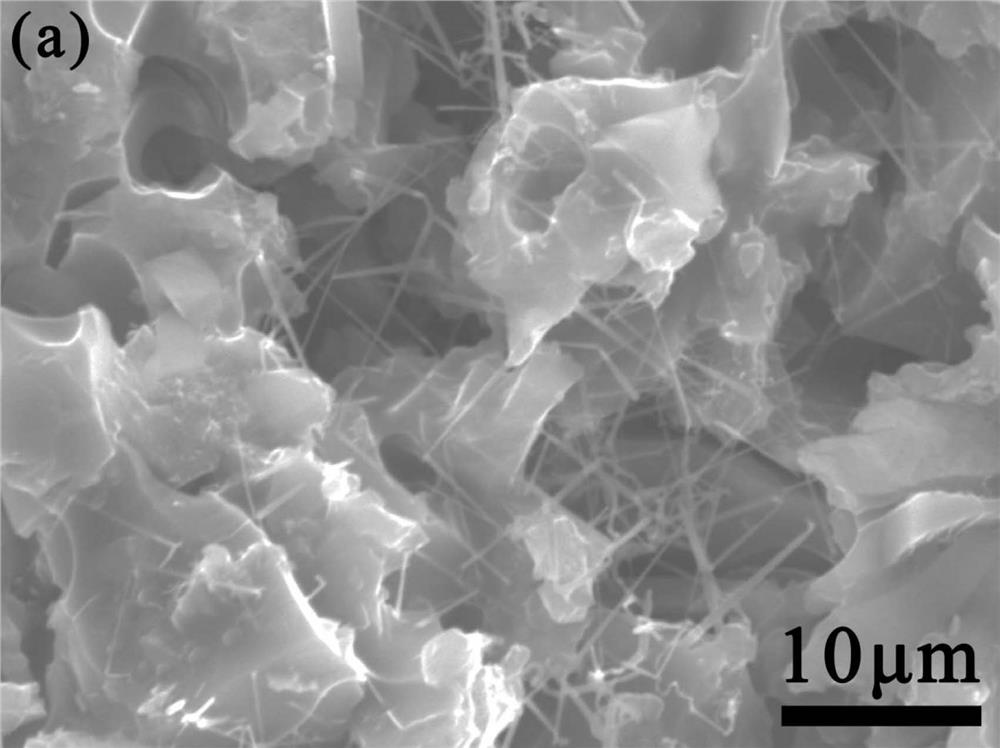

Embodiment 1

[0047] (1) Each component of the suspension slurry system is selected, wherein: the solvent is a mixed solvent of ethyl acetate and xylene. The dispersant is castor oil. The organic precursor is polycarbosilane (PCS) with a molecular weight of about 1500. The average particle size of silicon carbide powder is 50 μm. The average particle size of carbon black powder is 50nm. The catalyst is Fe(C 5 h 5 ) 2 , the particle size is between 100 and 500nm;

[0048] (2) The solid content (C+SiC) of the suspension slurry is 30 wt%, and C / SiC=0.2. The mass percentage of polycarbosilane (PCS) relative to the solvent is 30wt%. In the solvent, ethyl acetate:xylene=2:3. The dispersant is castor oil, and its mass percentage with the sum of silicon carbide ceramic powder and carbon black powder is 4wt%. The catalyst is Fe(C 5 h 5 ) 2 , its mass percentage with the organic precursor is 10wt%;

[0049] (3) Prepare the suspension slurry according to the above-mentioned design ratio, ...

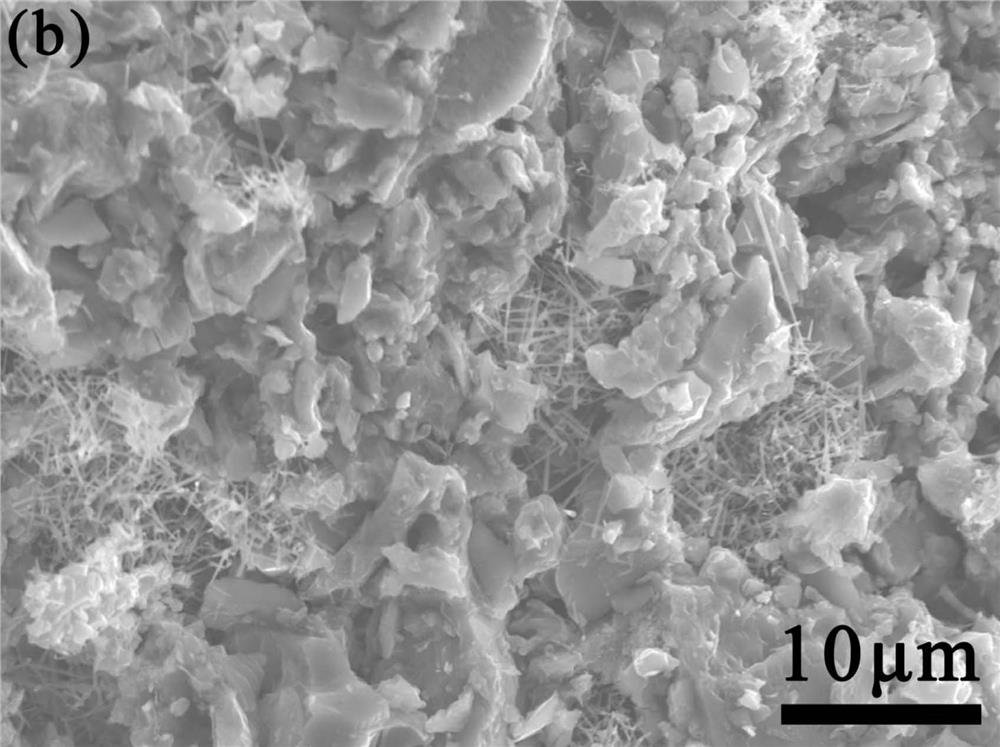

Embodiment 2

[0056] (1) Select each component of the suspension slurry system, wherein: the solvent is a mixed solvent of ethyl acetate and xylene; the dispersant is castor oil; the organic precursor is polycarbosilane (PCS) with a molecular weight of about 1500; The average particle size of silicon powder is 10μm; the average particle size of carbon black powder is 10nm; the catalyst is Fe(C 5 h 5 ) 2 , the particle size is between 100 and 500nm;

[0057] (2) The solid content (C+SiC) of the suspension slurry is 50 wt%, and C / SiC=0.5. The mass percentage of polycarbosilane (PCS) relative to the solvent is 45 wt%. In the solvent, ethyl acetate:xylene=2:3. The dispersant is castor oil, and its mass percentage with the sum of silicon carbide ceramic powder and carbon black powder is 3wt%. The catalyst is Fe(C 5 h 5 ) 2 , the mass percent with the organic precursor is 40wt%;

[0058] (3) Prepare the suspension slurry according to the above-mentioned design ratio, dissolve polycarbosi...

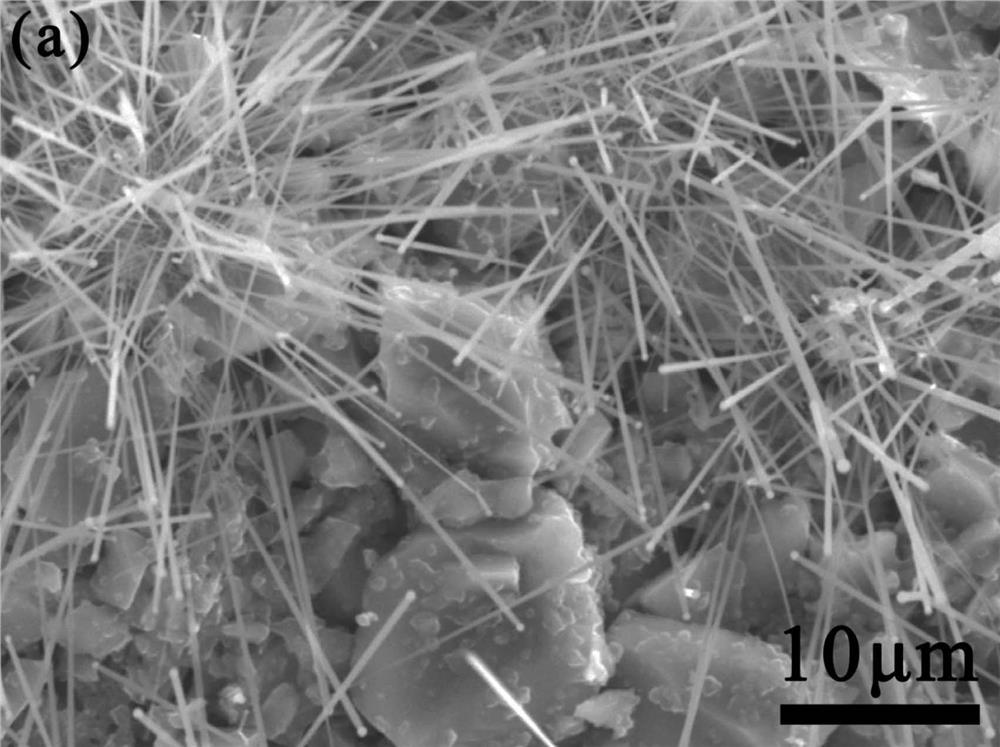

Embodiment 3

[0065] (1) Select each component of the suspension slurry system, wherein: the solvent is a mixed solvent of ethyl acetate and xylene; the dispersant is castor oil; the organic precursor is polycarbosilane (PCS) with a molecular weight of about 1500; The average particle size of silicon powder is 50μm; the average particle size of carbon black powder is 10nm; the catalyst is Fe(C 5 h 5 ) 2 , the particle size is between 100 and 500nm;

[0066] (2) The solid content (C+SiC) of the suspension slurry is 40 wt%, and C / SiC=0.4. The mass percentage of polycarbosilane (PCS) relative to the solvent is 40wt%. In the solvent, ethyl acetate:xylene=2:3. The dispersant is castor oil, and its mass percentage with the sum of silicon carbide ceramic powder and carbon black powder is 6wt%. The catalyst is Fe(C 5 h5 ) 2 , its mass percentage with the organic precursor is 20wt%;

[0067] (3) configure the suspension slurry according to the above-mentioned design ratio, dissolve polycarbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com