Novel multifunctional automobile seat headrest wrapped by polyurethane through injection molding

A car seat, polyurethane technology, applied in the direction of vehicle seats, headrests, vehicle parts, etc., can solve problems such as the inability to realize high-end functions such as headrest forward and backward movement adjustment, and the bottleneck of the overall seat grade, and achieve verification procedures and time. The effect of shortening, simplifying quality control and other links, reducing costs and potential risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

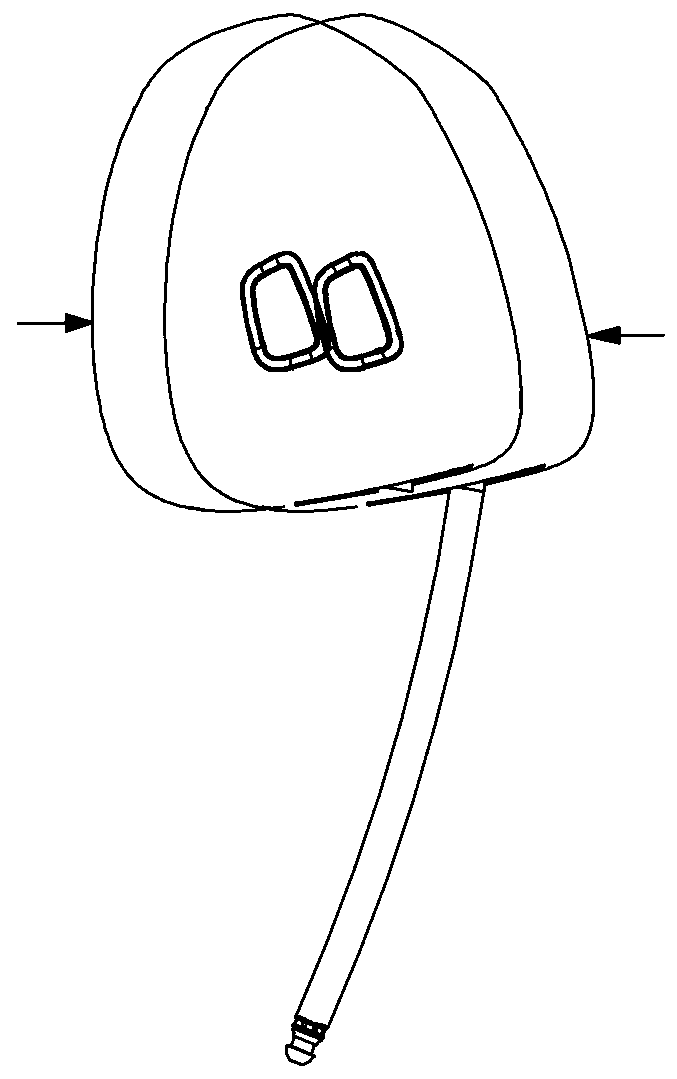

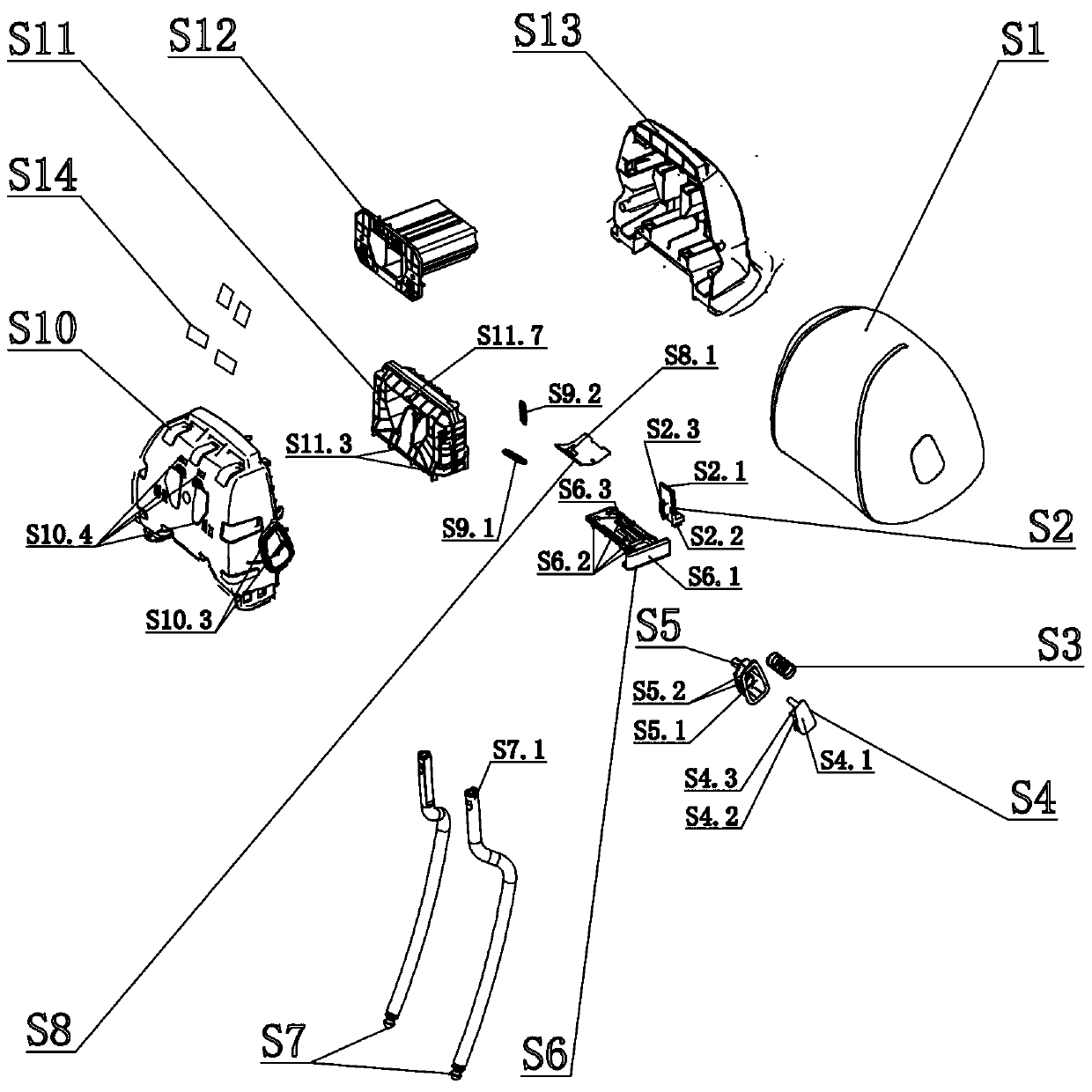

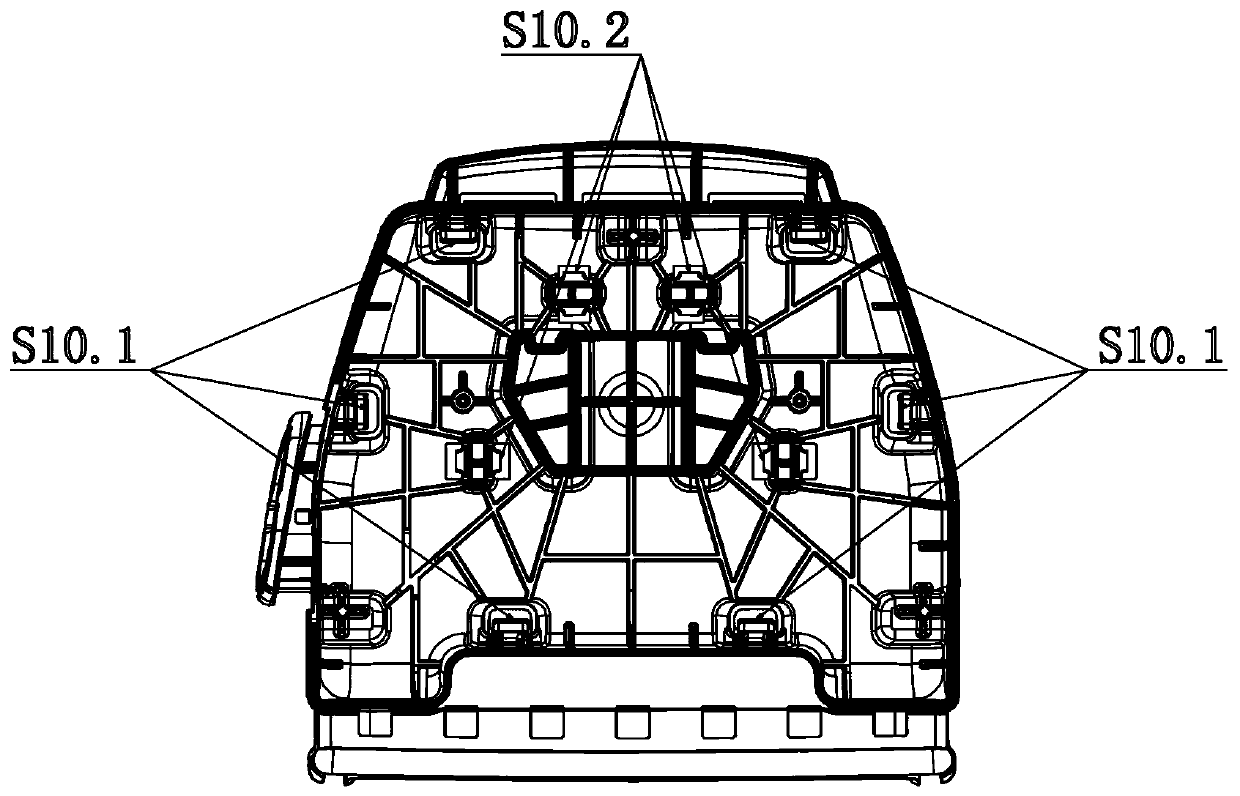

[0020] Such as figure 1 and figure 2 As shown, a new type of polyurethane injection molding wrapped multifunctional car seat headrest. The carrier part S11 and the sliding part S12 are arranged in the cavity of the headrest rod S7, and the upper end of the headrest rod S7 is fixedly connected with the carrier part S11. The fastened front cover S10 and the rear cover S13 are connected with the sliding part S12. The mechanism slides back and forth in the sliding cavity of the carrier part S11, driving the headrest to move back and forth; after the front cover S10 and the rear cover S13 are matched, first use the tape strip S14 to align the process hole S10.4 on the front cover S10 of the headrest. Sealing is performed to ensure that the outer side of the headrest functional module is sealed, and then the modified polyurethane layer S1 is injected to form the headrest assembly. The patent of the present invention uses the process of secondary injection molding to melt and coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com