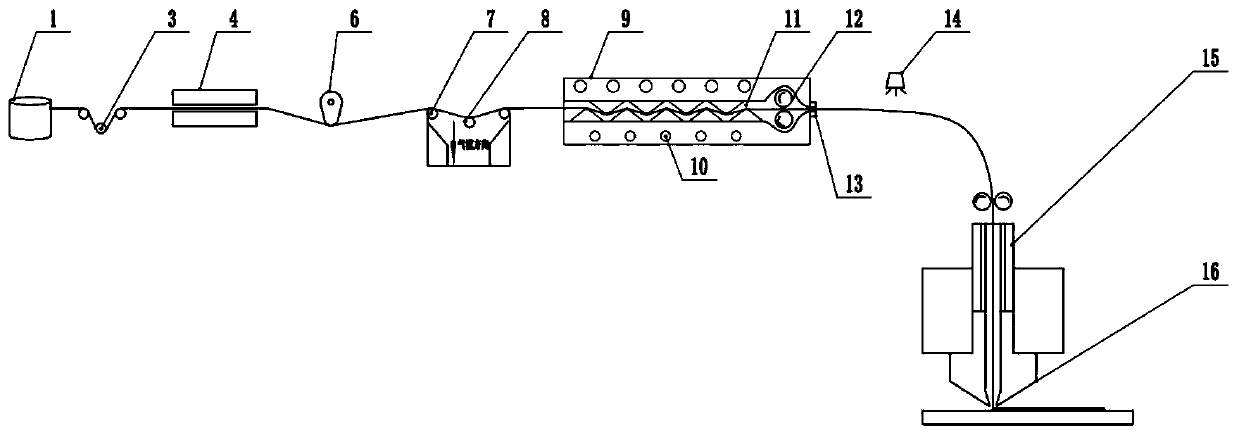

Continuous fiber melt impregnation 3D printing device and process

A continuous fiber, 3D printing technology, applied in the field of composite material manufacturing, can solve the problems of short residence time, long melting time, unfavorable fiber impregnation, etc., and achieve the effect of improving utilization rate and impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

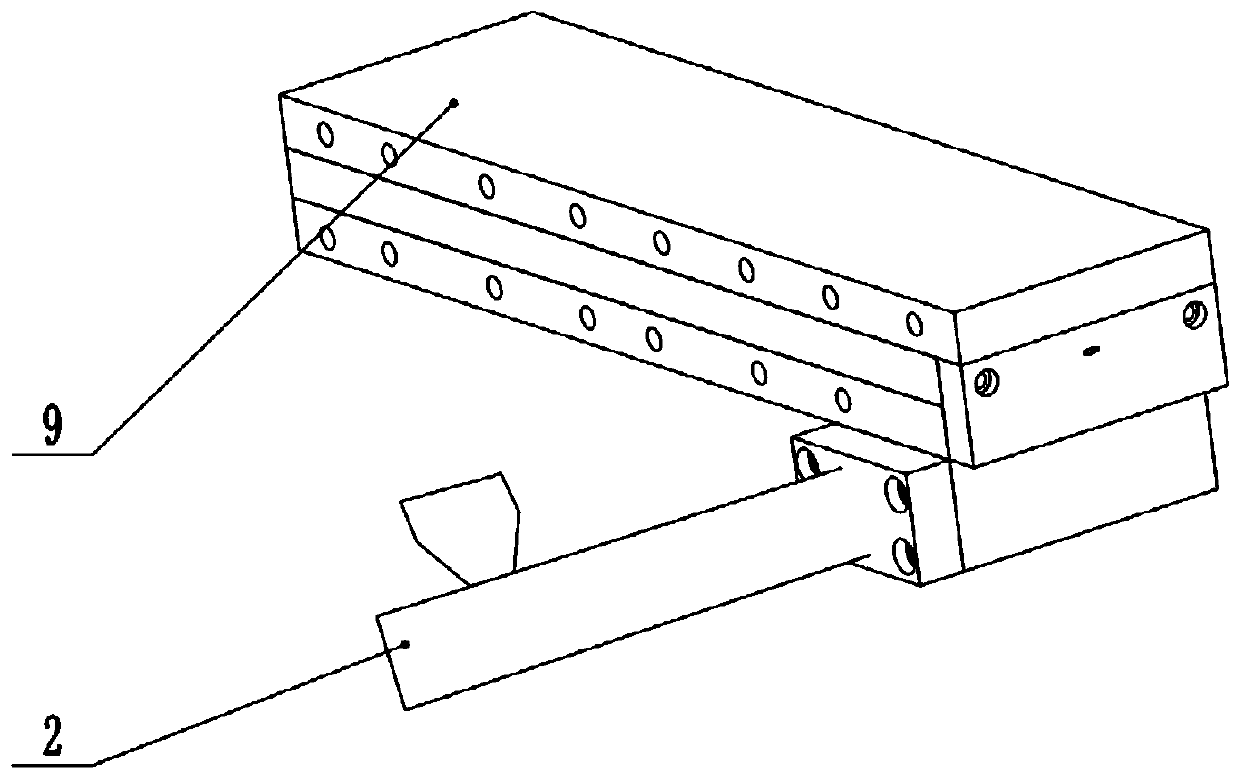

Method used

Image

Examples

Embodiment 1

[0039] Using the continuous fiber reinforced thermoplastic resin melt impregnation 3D printing device and 3D printing method of the present invention, wherein the parameters are:

[0040] The wrapping angle of the wave-shaped flow channel in the wire material infiltration mold 9 is 300°, the flow channel gap is 8 mm, the pulling speed of the inner traction roller 12 is 3 m / min, the diameter D of the shaping die 13 is 0.7 mm, and the length is 15 mm. times the diameter D.

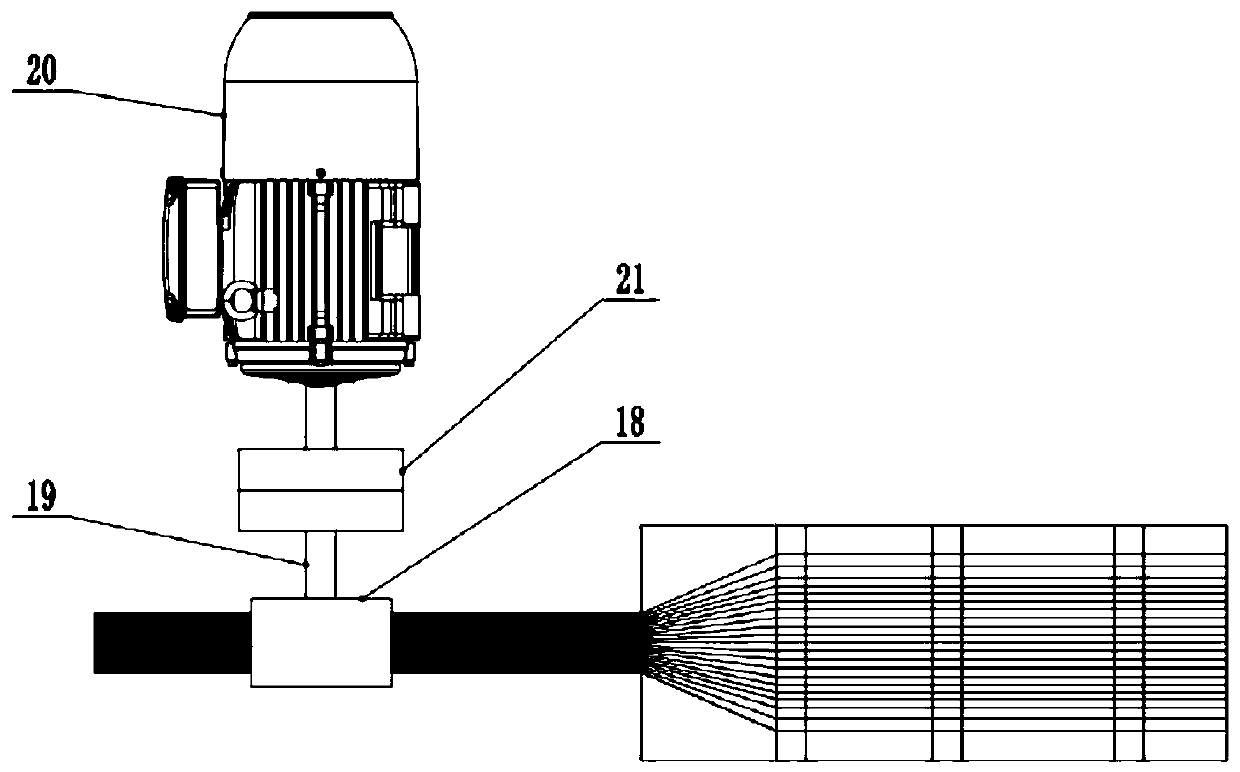

[0041] The swing frequency of the cam 18 in the swing device 6 is 10r / min, and the eccentric amplitude is 10mm. The air velocity of the gas-assisted device 17 is 2m / min, the width of a single bundle of fibers spread by the gas-assisted swing device is 15mm, and the thickness is 0.03mm, the preheating temperature of the infrared radiation device 4 is 100°C, and the diameter of the shaping die 13 is The diameter of the obtained continuous fiber prepreg is 1mm.

[0042] The divergence angle α of the nozzle 16...

Embodiment 2

[0046] Using the same continuous fiber reinforced thermoplastic resin melt impregnation 3D printing device and process as in Example 1, wherein the parameters are:

[0047] The wrapping angle of the wave-shaped flow channel in the wire soaking mold 9 is 375°, the flow channel gap is 8 mm, the pulling speed of the inner traction roller 12 is 4 m / min, the diameter D of the shaping die 13 is 1 mm, and the length is 15 times The diameter D.

[0048] The swing frequency of the cam 18 in the swing device 6 is 15r / min, and the eccentric amplitude is 12mm. The air velocity of the gas-assisted device 17 is 6m / min, the width of a single bundle of fibers spread by the gas-assisted swing device is 20mm, the thickness is 0.05mm, the preheating temperature of the infrared radiation device 4 is 150°C, and the diameter of the shaping die 13 is The diameter of the obtained continuous fiber prepreg is 1 mm.

[0049] The divergence angle α of the nozzle 16 of the 3D printer 15 is 45°, the leng...

Embodiment 3

[0054] Using the same continuous fiber reinforced thermoplastic resin melt impregnation 3D printing device and process as in Example 1, wherein the parameters are:

[0055] The covering angle of the wave-shaped flow channel in the wire material infiltration mold 9 is 450°, the flow channel gap is 8mm, the traction speed of the inner traction roller 12 is 5m / min, the diameter D of the shaping die 13 is 1.2mm, and the length is 20mm. times the diameter D.

[0056] The swing frequency of the cam 18 in the swing device 6 is 20r / min, the eccentric amplitude is 15mm, the airflow velocity of the gas-assisted swing device 17 is 8m / min, the width of a single bundle of fibers spread by the gas-assisted swing device is 25mm, and the thickness is 0.03 mm, the preheating temperature of the infrared radiation device 4 is 150° C., the diameter of the shaping die 13 is 1 mm, and the diameter of the obtained continuous fiber prepreg is 1.2 mm.

[0057] The divergence angle α of the nozzle 16 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com