Preparation method and application for platinum/cuprous oxide film compound

A technology of cuprous oxide and composites, which is applied in the field of electrocatalysis, can solve the problems of difficult microscopic shape control, complex preparation process of cuprous oxide film, and high requirements for reaction devices, and achieve superior stability, good electron transport ability, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention discloses a method for preparing a platinum / cuprous oxide thin film composite, which is characterized in that: using copper flakes, dilute hydrochloric acid, copper nitrate, platinum acetylacetonate, and ultrapure water as raw materials to prepare the platinum / cuprous oxide composite, The platinum / cuprous oxide composite is a platinum cuprous oxide film loaded with turquoise in shape, and its appearance is crisscrossed linear, with a length of about 20 μm and a diameter of about 150 nm; specifically including the following steps:

[0023] (1) Use dilute hydrochloric acid to remove oxides on the surface of the copper sheet, and then use ultrapure water to wash the dilute hydrochloric acid on the surface of the copper sheet;

[0024] (2) Prepare 100ml of copper nitrate solution for use;

[0025] (3) Weigh the platinum acetylacetonate to dissolve, and put the platinum acetylacetonate dissolved in step (2) and the copper flakes washed in step (1) into the copper nitr...

Embodiment 1

[0033] (1) Cut the copper sheet into 1*1cm 2 , Soak in dilute hydrochloric acid to remove oxides on the surface of the copper sheet, and then wash the dilute hydrochloric acid on the surface of the copper sheet with ultrapure water, and set aside;

[0034] (2) Configure 100ml 5*10 -3 mol / L copper nitrate solution, ready for use;

[0035] (3) Accurately weigh 7 mg of platinum acetylacetonate and dissolve it. After dissolving, add the platinum acetylacetonate solution and the copper flakes in step (1) to the copper nitrate solution in step (2) above to grow at 40°C;

[0036] (4) After 1 day of growth, it can be observed that a layer of blue-green product has grown on the surface of the copper sheet. The product can be obtained by rinsing it with ultrapure water.

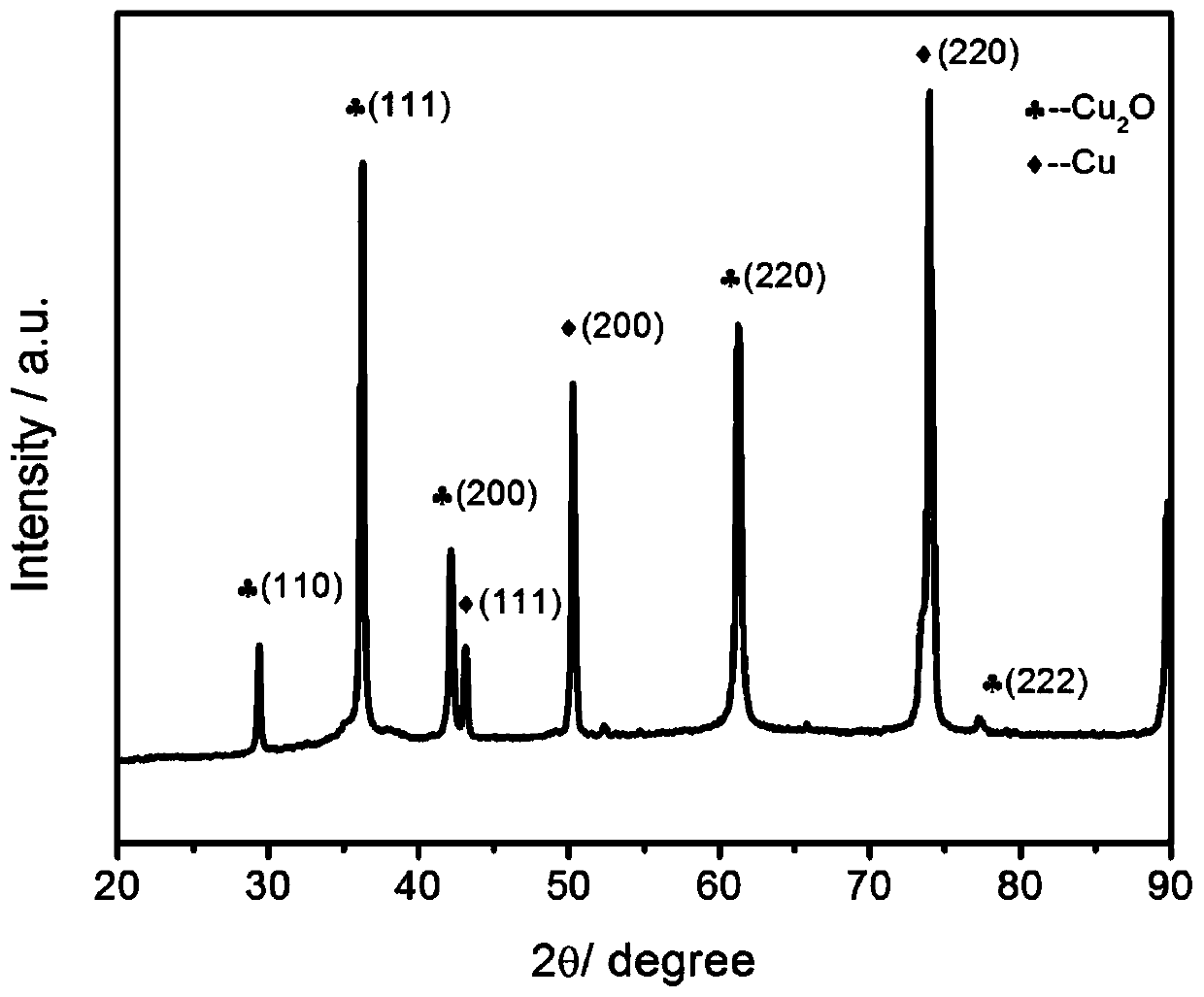

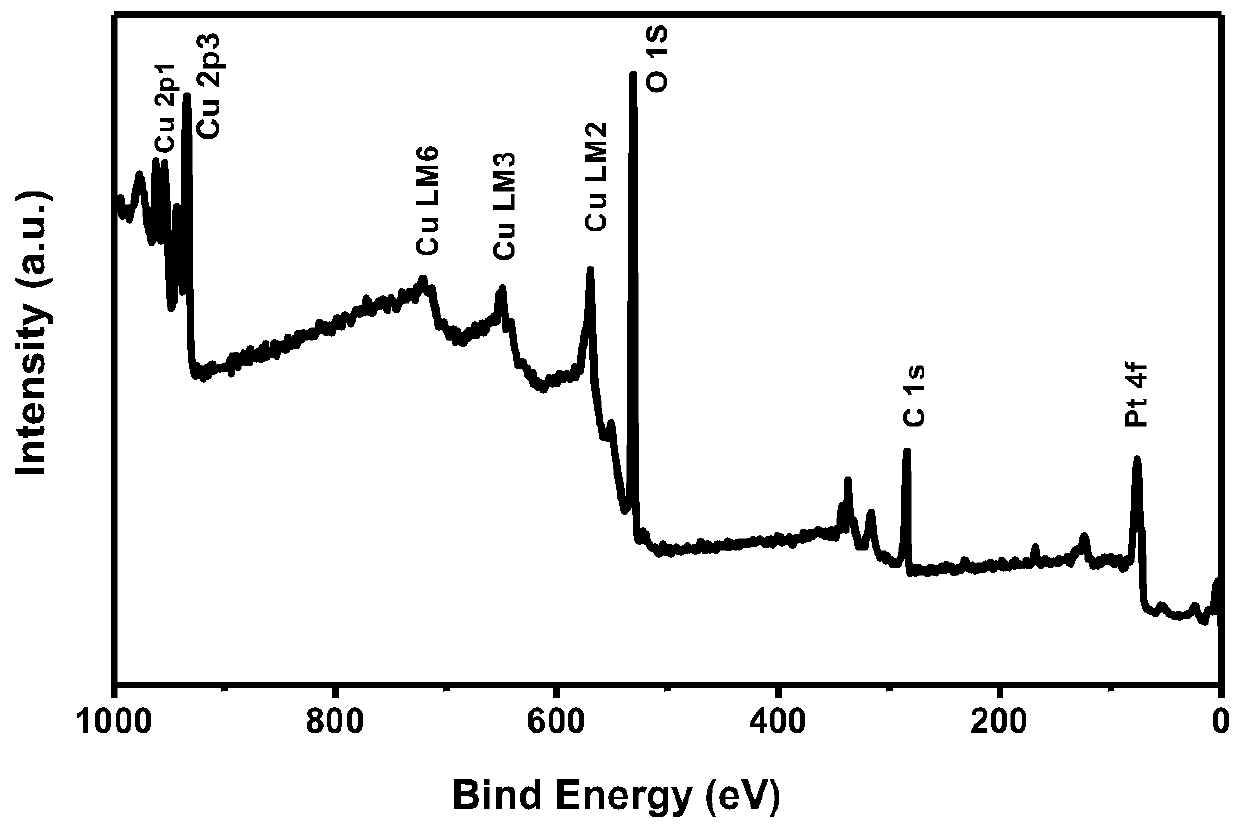

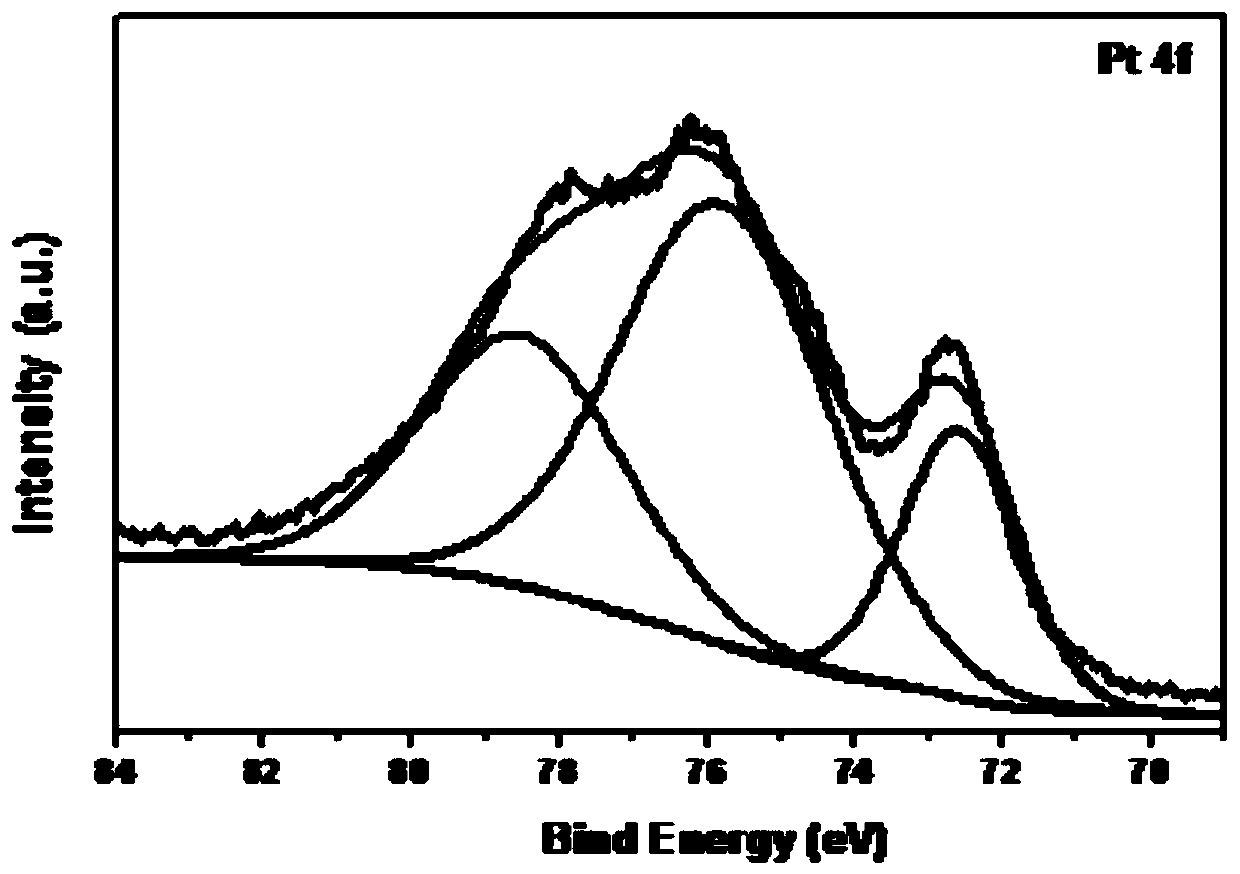

[0037] The product obtained in step (4) is subjected to XRD and XPS determination, such as Figure 1-3 As shown, figure 1 The middle spectrum shows obvious cuprous oxide, and the peak at about 42° is a copper base peak; fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com