Hydraulic spool valve

A hydraulic spool valve and valve hole technology, applied in the field of hydraulic spool valves, can solve the problems of increased leakage, no detailed investigation of flow loss, increased wear of the control piston and housing, etc., to achieve the effect of high-quality control edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

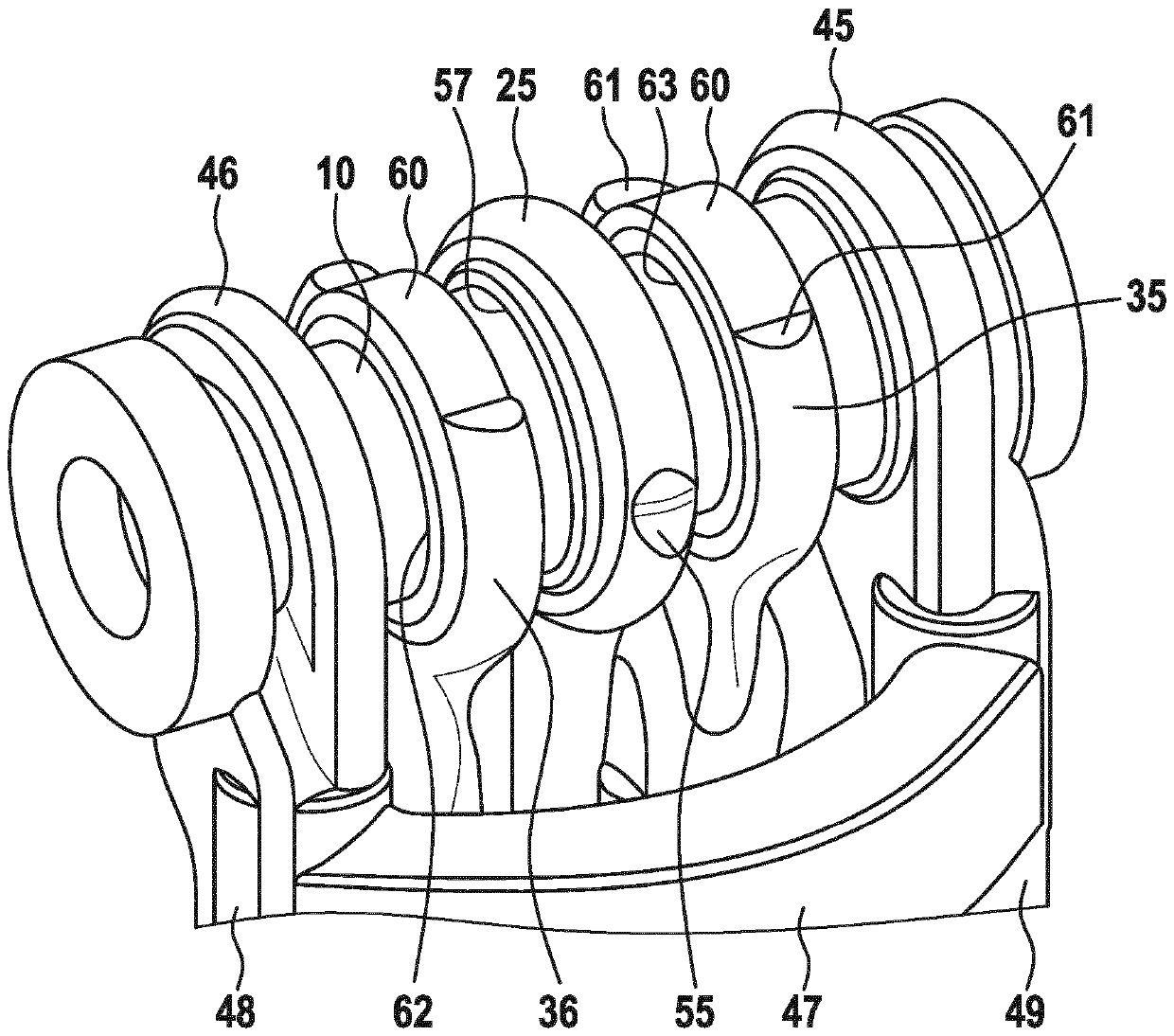

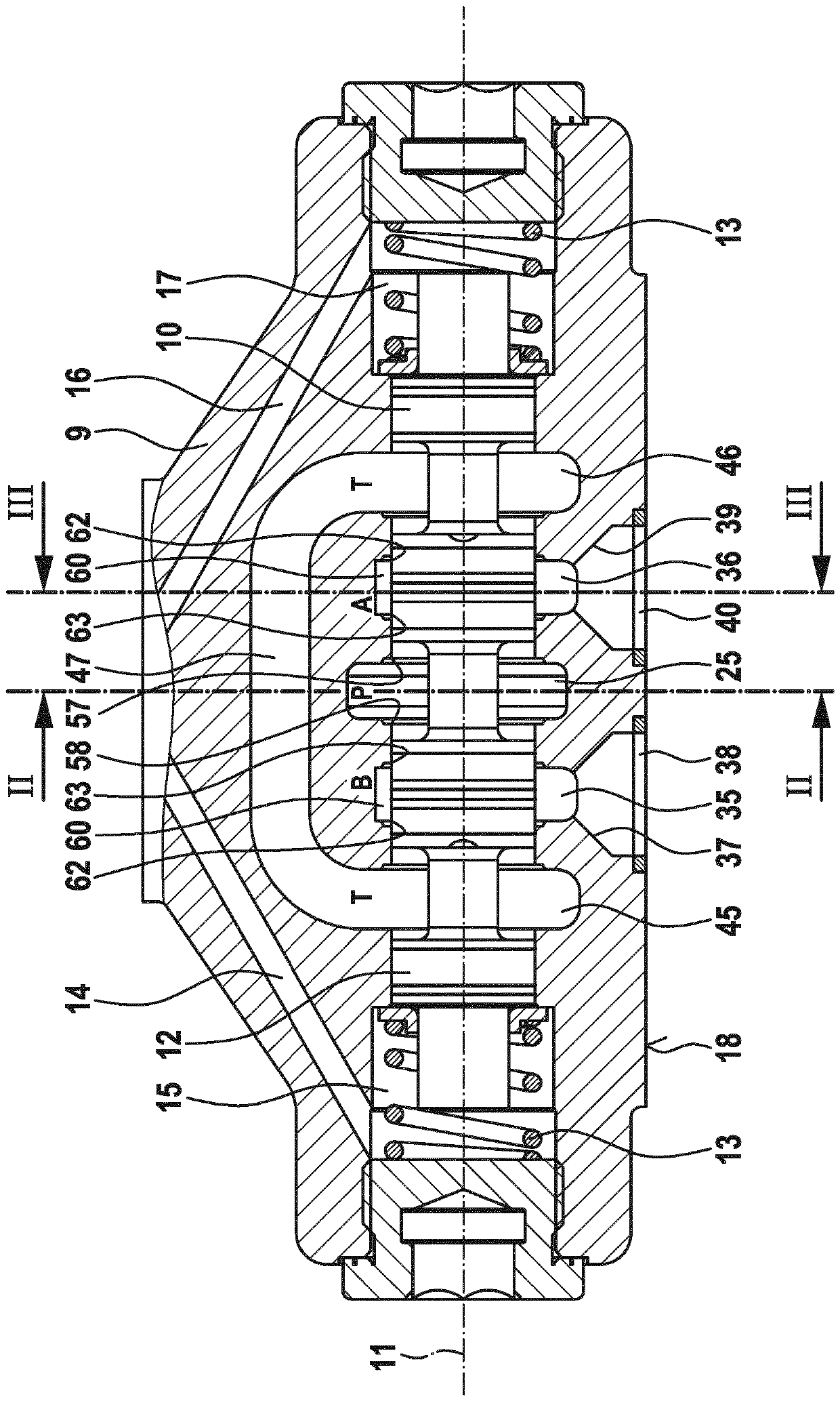

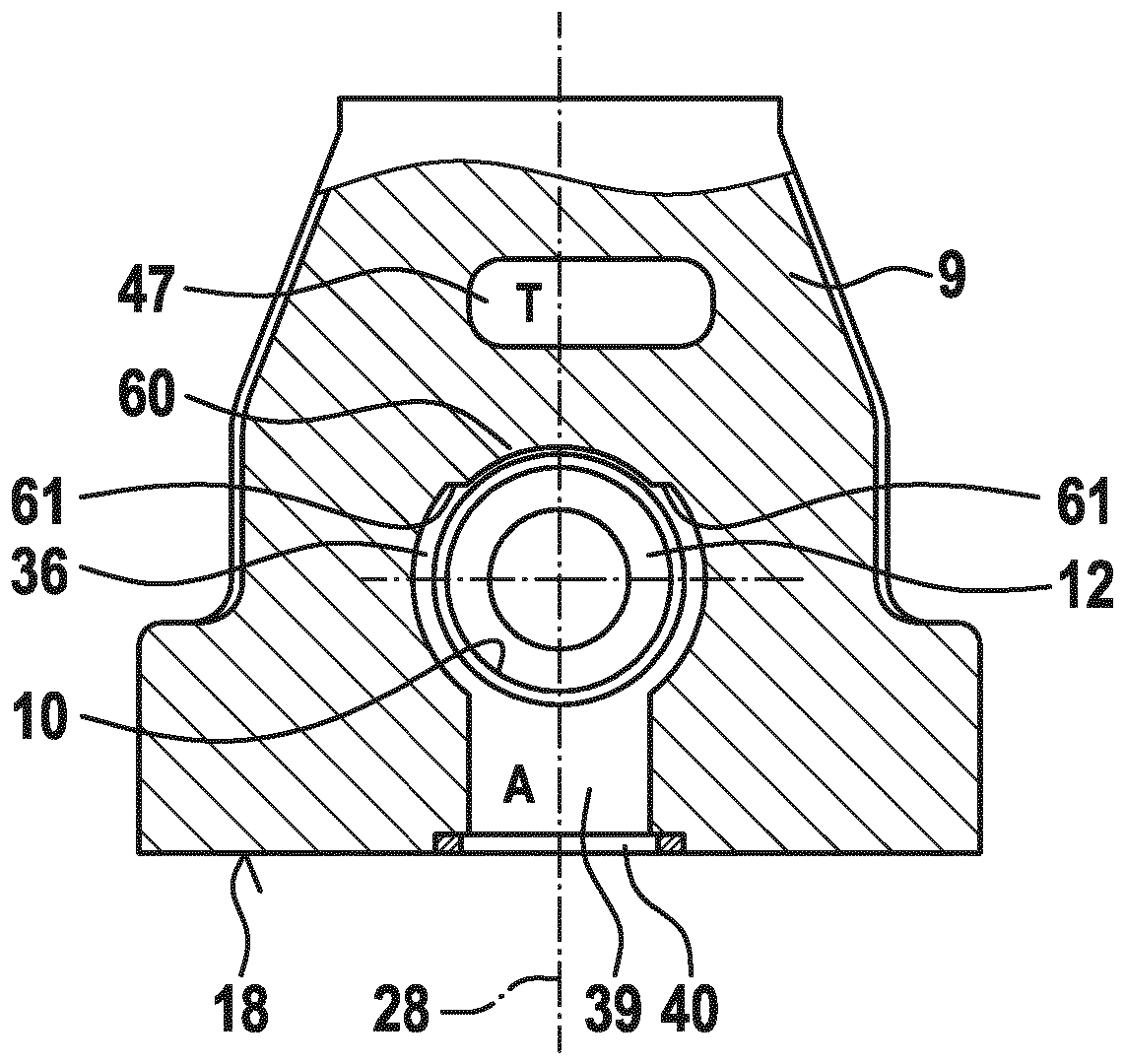

[0056] The hydraulic slide valve shown is a 4 / 3-way valve, ie a directional valve with four ports and three switching positions. The four connections are a pump connection, a tank connection and two load connections to which, for example, a double-acting hydraulic cylinder is connected.

[0057] The spool valve is electrohydraulically pilot controlled. The slide valve has a valve housing 9 , which is penetrated by a valve bore 10 with a center axis 11 , in which a control piston 12 is movable in two opposite directions. The control piston 12 is centered by means of two centering springs 13 in a central position in which all ports are locked relative to each other. A pilot control channel 14 leads from an electromagnetically actuatable pilot valve, not shown, to a first pressure chamber 15 upstream of one end side of the control piston 12 , and a second pilot control channel 16 leads from the pilot valve to a A second pressure chamber 17 upstream of the other end of the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com