Tire X-ray defect detection method for carrying out re-ranking by utilizing background features

A defect detection and defect technology, applied in the fields of computer vision and industrial inspection, can solve problems affecting traffic driving safety, high production requirements, air bubbles, etc., and achieve the effects of avoiding inefficiency, enhancing robustness, and increasing probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present application will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

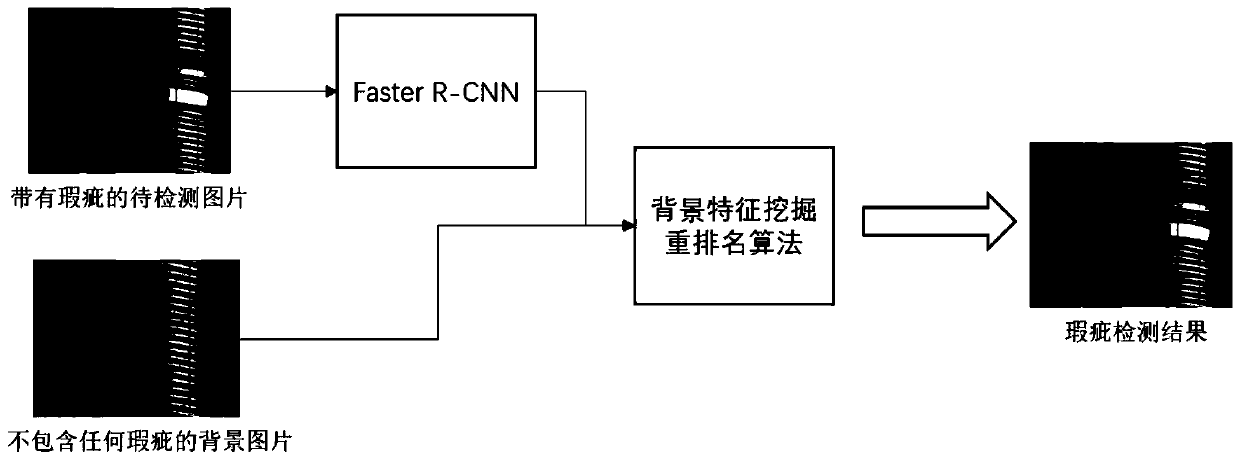

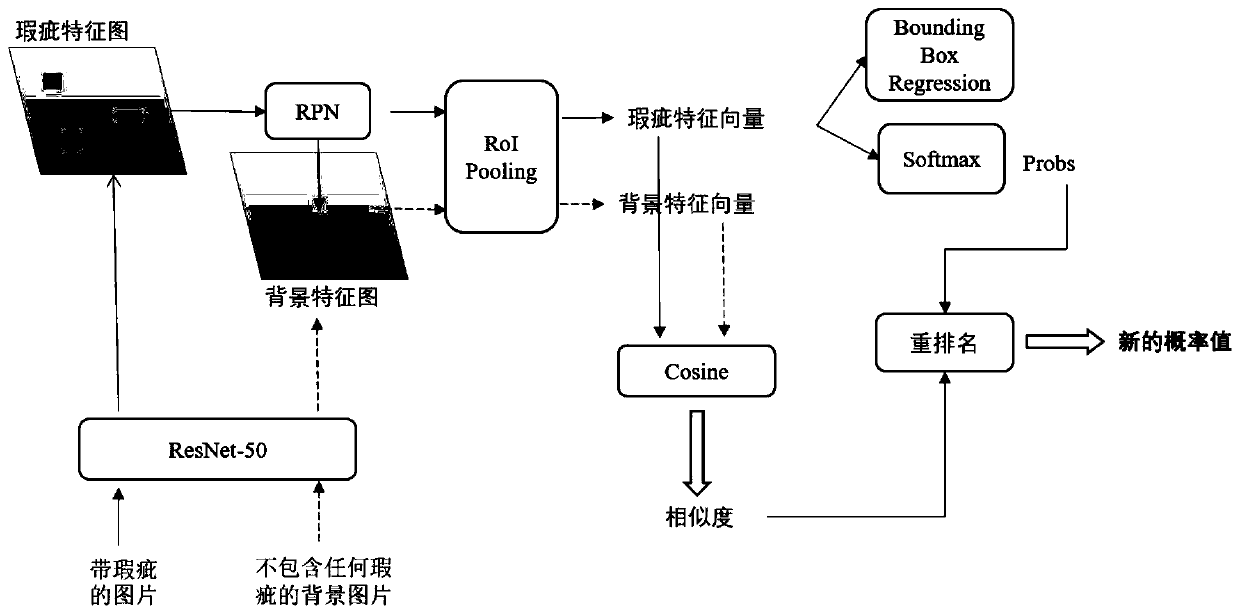

[0037] refer to Figure 1-2 , the purpose of this example is to realize the defect detection of tire X-ray images according to the present invention. The process of the method includes steps such as data collection, image preprocessing, model training, and background feature re-ranking for defect detection, such as image 3 As shown, the specific implementation process diagram is as follows:

[0038] Step (1): Data collection. In this example, a total of 10,919 defect pictures are marked, and each defect picture marks the location and type of all defects. The types are marked in the form of 0, 1, 3, ..., 5, and the specific types are shown in Table 1. This implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com