Optical image automatic capturing method of composite detection condition

An optical imaging and composite detection technology, applied in the detection field, can solve problems such as inability to obtain defect identification information, time-consuming, and inability to detect holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

[0045] According to the prior art, the conventional automatic optical inspection method for the object under test cannot simultaneously capture images under different optical conditions for comparison. Therefore, the present invention proposes an automatic optical image capture method with complex detection conditions to solve the traditional problems to be improved, so as to improve the accuracy and efficiency of detection results, and will be described in detail below.

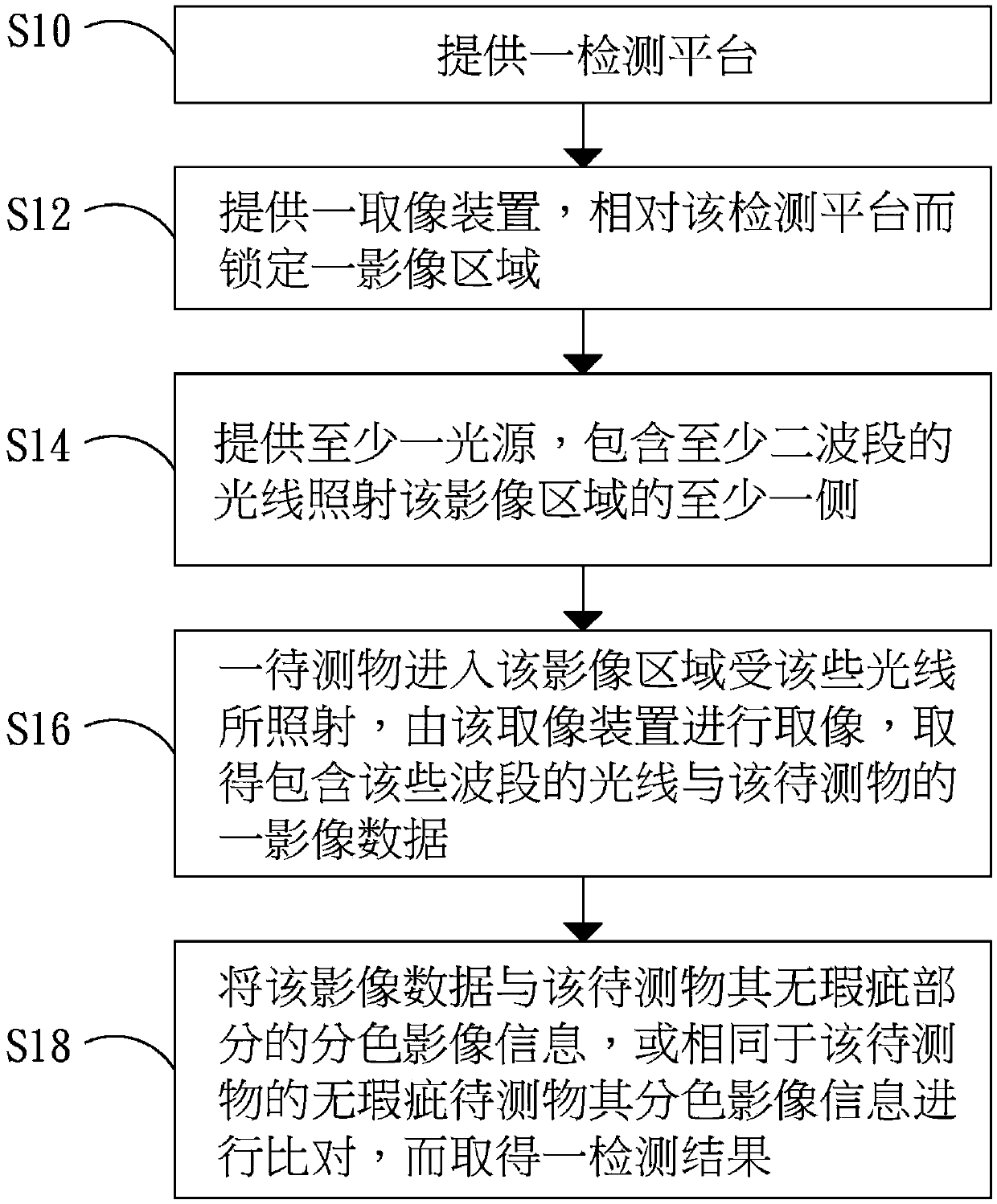

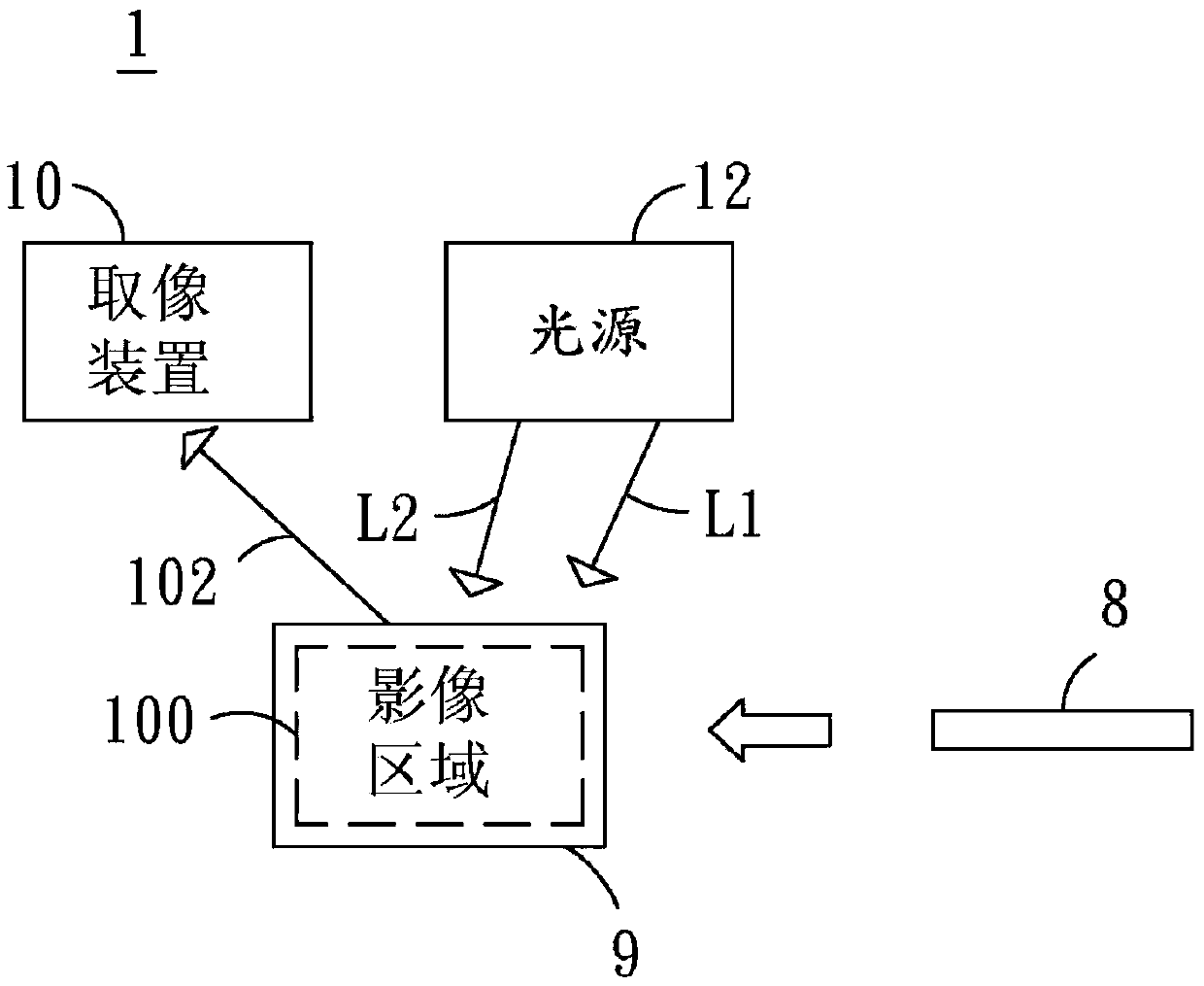

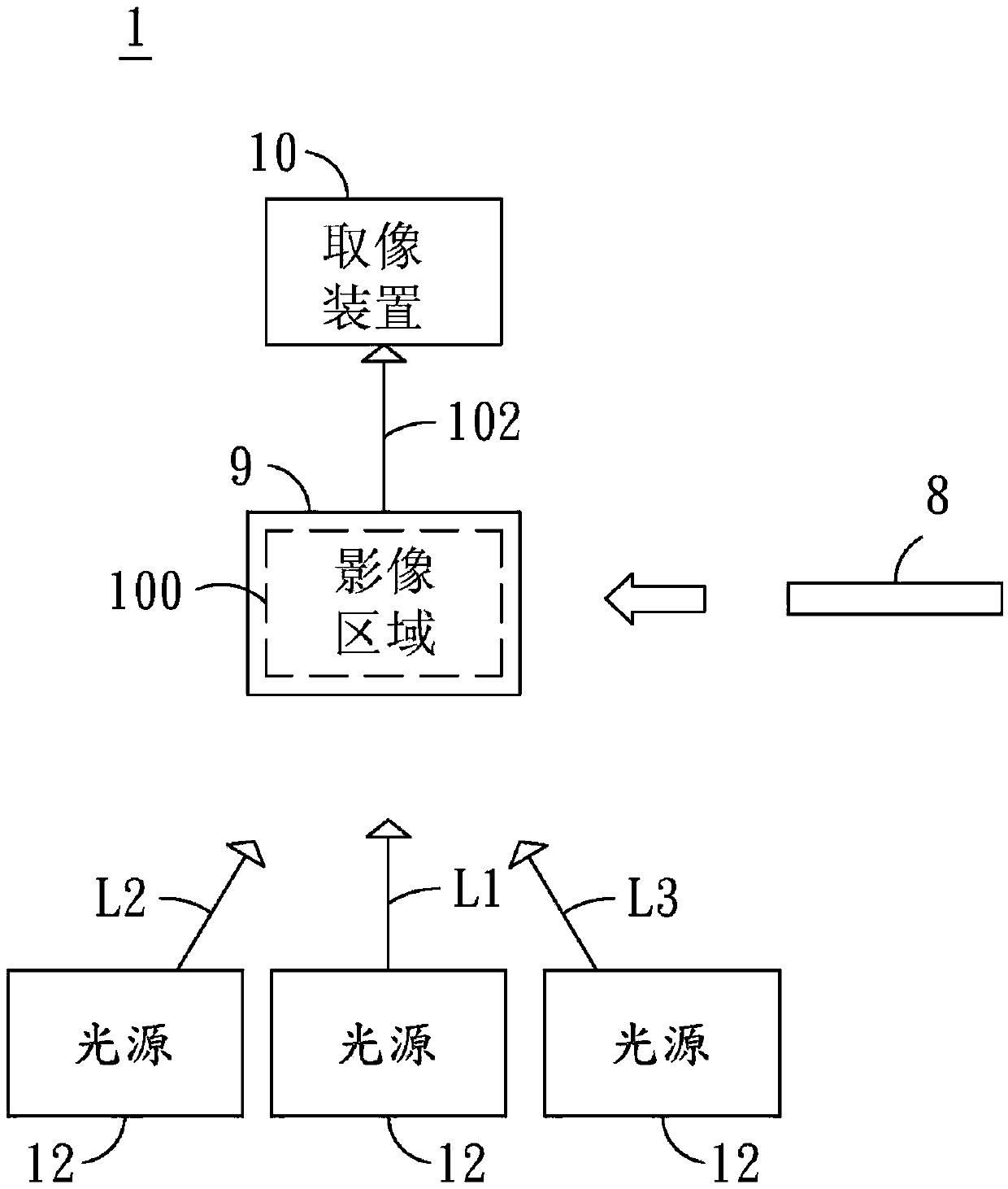

[0046] Here is a description of an optical image automatic capture method with complex detection conditions of the present invention, please refer to figure 1 , which is a flow chart of the method for automatically capturing optical images with complex detection cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com