Heat-conducting gel with high heat conductivity and low oil output performance and preparation process thereof

A high thermal conductivity, gel technology, used in heat exchange materials, chemical instruments and methods, etc., can solve the problems of large curing shrinkage, long operation time, affecting production efficiency, etc., to improve heat dissipation efficiency and service life, good The effect of liquidity and strong practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the embodiments.

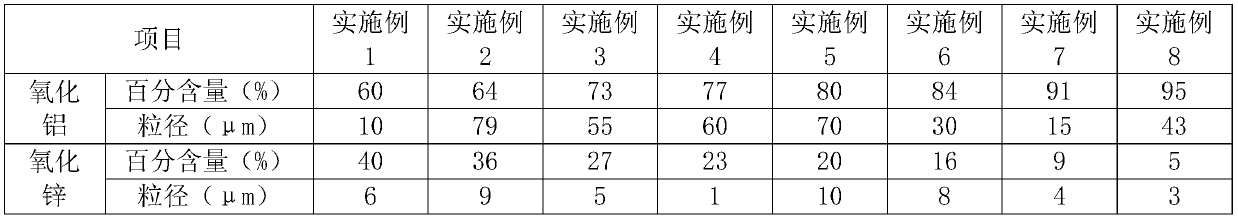

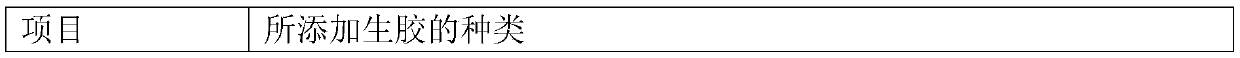

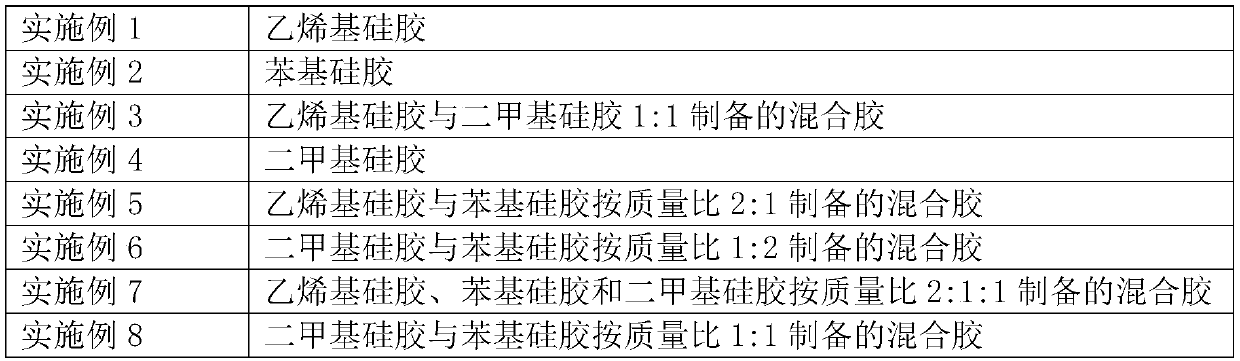

[0046] Embodiment 1-8 carries out batching according to following batching table

[0047] project Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Example 7 Example 8 Powder (g) 65 90 75 69 84 91 85 95 Silicone oil (g) 30 11 26 24 23 9 19 5 Raw rubber (g) 0.5 0.01 10 5 3 2 1 7 Curing agent (g) 0.3 4 3.3 5 0.1 0.9 1.5 2.7 Coupling agent (g) 0.3 0.1 2 1.5 3 2.4 0.8 1.9 Stabilizer (g) 1 2 / / / / 1 1 Flame retardant (g) / / 2 1 / 2 / 1 Colorant (g) / 1 1 1 / / 2 1 Thixotropic agent (g) 1 / / 1 / 1 / 1

[0048] It should be noted that, in addition to the additive addition methods in the above examples, those skilled in the art can add other types of additives according to the actual situation, and can also adjust the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com