Process and system for producing cyclohexane plasticizer by liquid phase hydrogenation of o-benzene plasticizer

A technology of o-benzene plasticizer and liquid phase hydrogenation, which is applied in the field of liquid-phase hydrogenation of o-benzene plasticizer to produce cyclohexane plasticizer, and can solve the problem of long process reaction time and high moisture content in product test results. , unstable product quality and other problems, to achieve the effect of good separation and purification effect, good mixing heating and separation and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

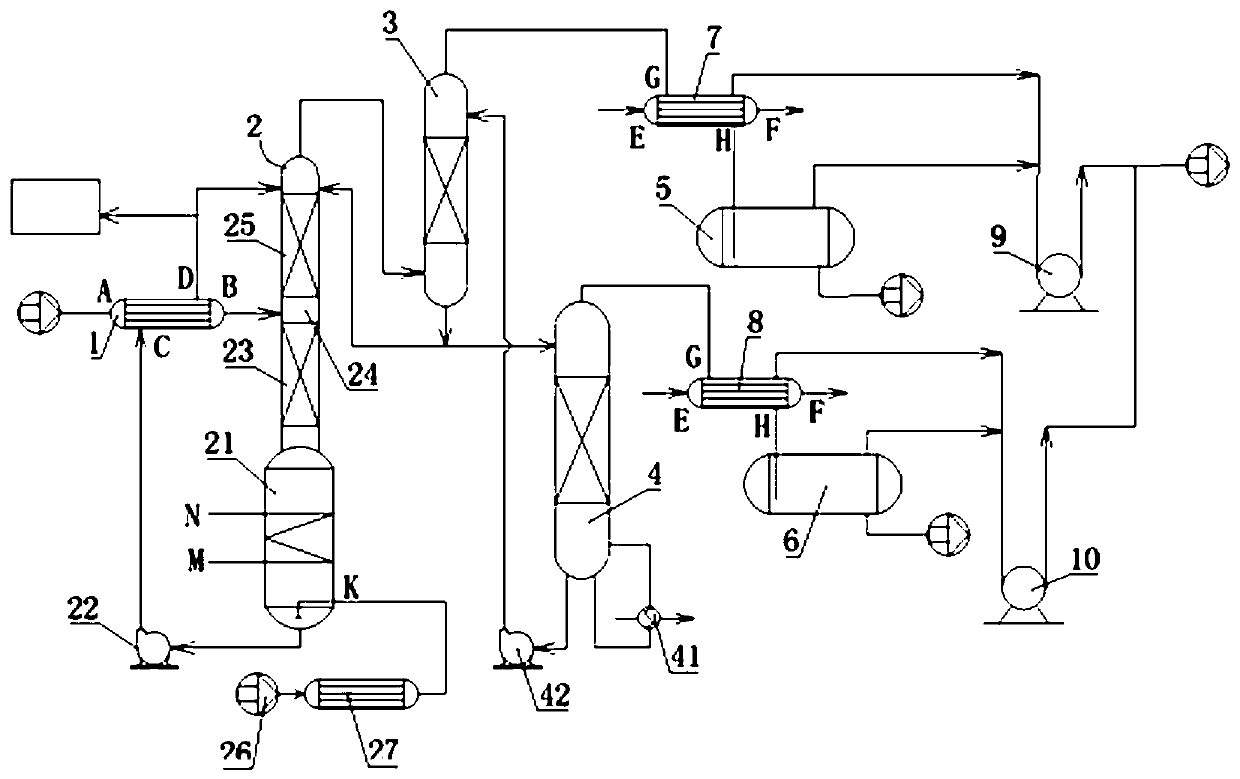

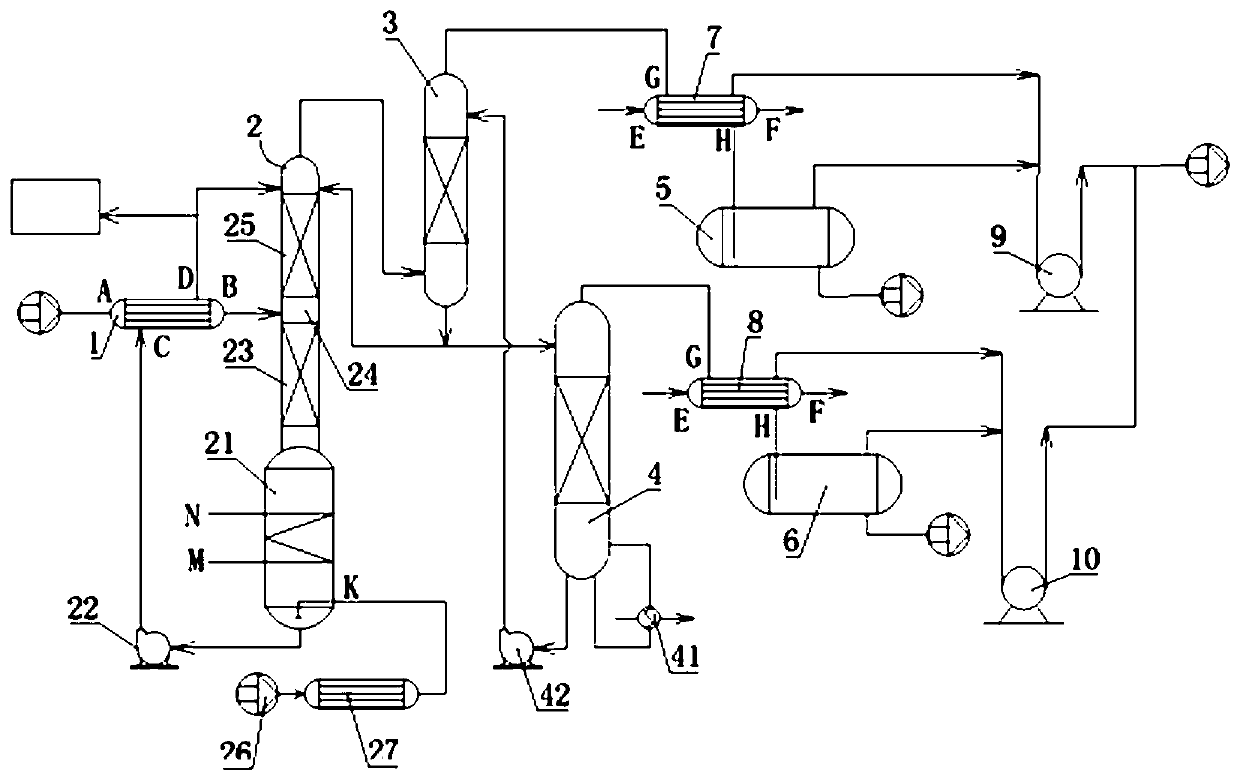

[0019] see figure 1 , which shows a schematic diagram of the production system of cyclohexane plasticizers produced by liquid-phase hydrogenation of o-phthalic plasticizers in the present invention, and its specific structure is as follows:

[0020] Including feed preheater 1, vacuum distillation tower 2, extraction and separation tower 3, solvent regeneration tower 4, light component tank 5, heavy component tank 6, first condenser 7, second condenser 8, first vacuum pump 9. The second vacuum pump 10. Wherein, the feed preheater 1 is provided with the first feed port A and the first discharge port B communicated therewith, the second feed port C and the second discharge port D communicated therewith; the first condenser 7. The second condenser 8 is respectively provided with a water inlet E and a water outlet F connected thereto, a feed inlet G and a discharge outlet H connected thereto; the bottom of the vacuum distillation tower 2 is provided with an inert gas inlet K, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com