Printing device and frame encapsulating frit printing device

A technology of printing equipment and sealing glue, which is applied in the field of display panel preparation, and can solve the problems of shortening the life of the mask plate, printing shape and height, and wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

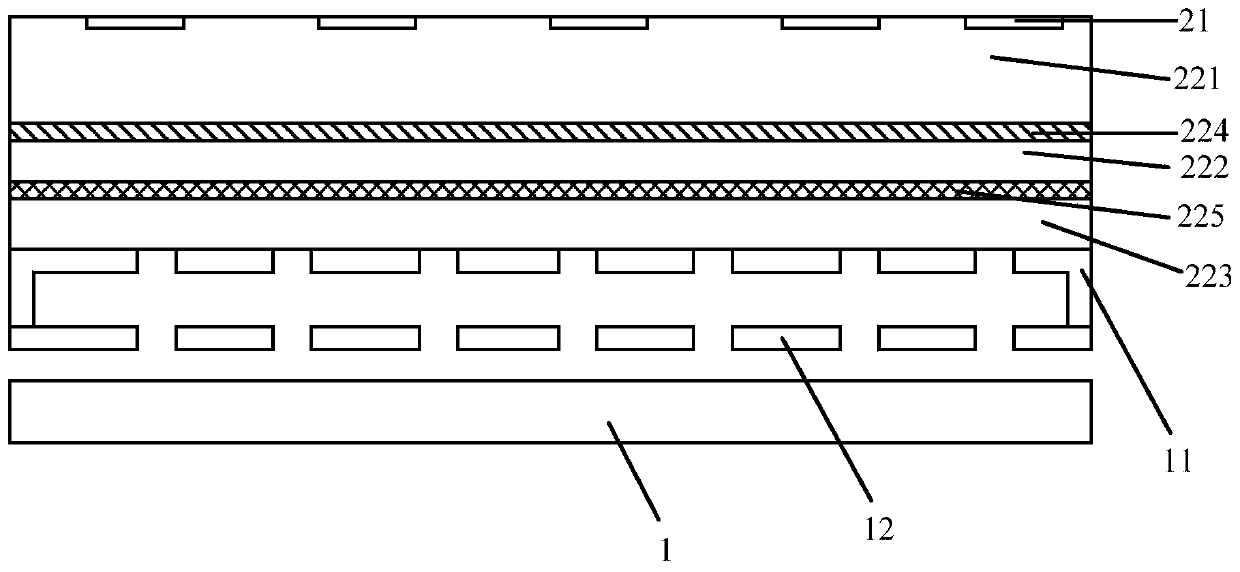

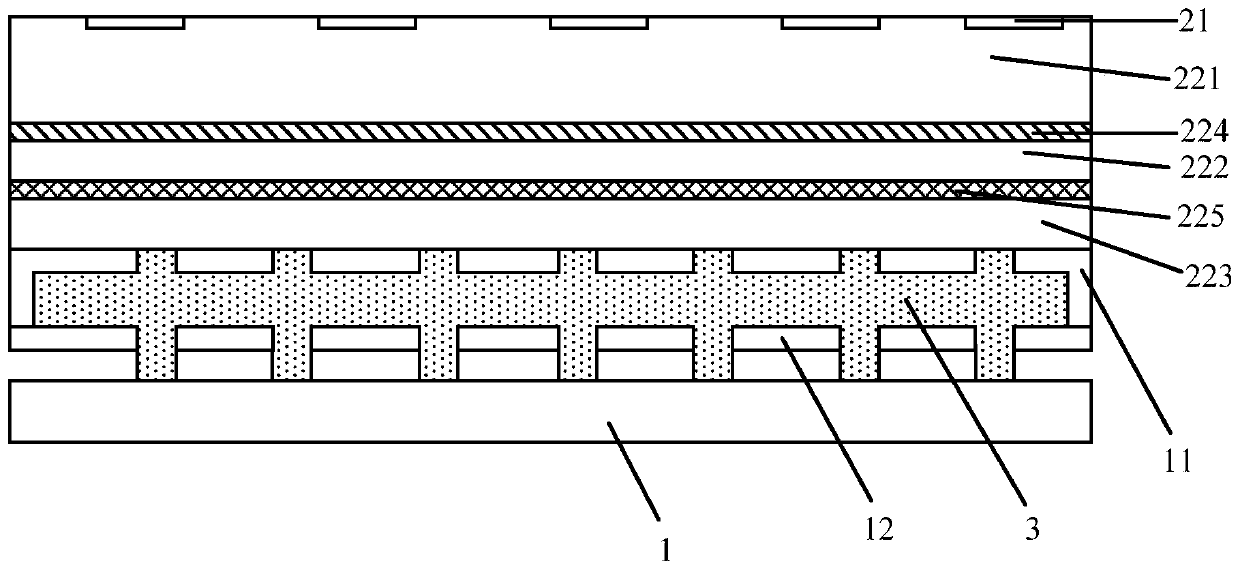

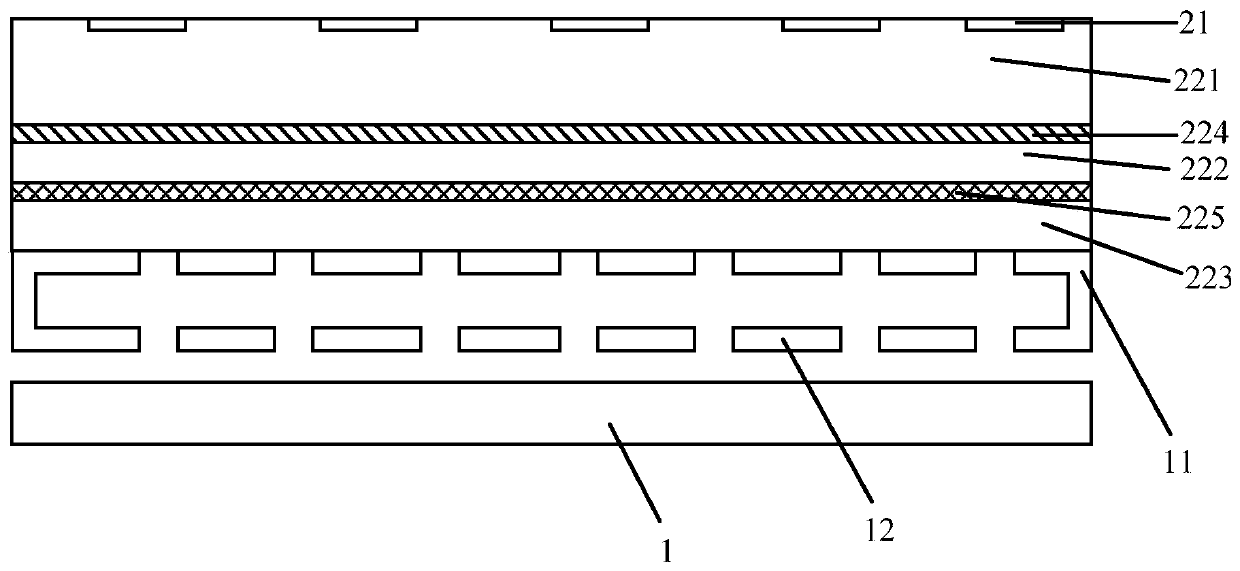

[0026] like Figures 1 to 3 As shown, this embodiment provides a printing device for printing a sealant on the display substrate 1 . Among them, the sealing glue is preferably glass glue. The printing device provided in this embodiment includes: a storage chamber and an air pressure chamber. Wherein, it includes a main body 11 and a reticle 12, the main body 11 is used to accommodate the sealant material 3; the reticle 12 is arranged on the side of the main body 11 close to the display substrate 1, and the reticle 12 has a patterned opening area; an air pressure chamber, which communicates with the accommodation chamber, and is used to adjust the air pressure of the accommodation chamber, so that the sealant material 3 in the accommodation chamber overflows through the opening area of the reticle 12 under the action of air pressure.

[0027] In the printing device provided in this embodiment, the air pressure of the accommodation chamber is adjusted through the air pressur...

Embodiment 2

[0040] This embodiment provides a frame sealant printing device, including any printing device provided in Embodiment 1.

[0041] Preferably, the sealant printing device provided in this embodiment further includes a sealant injection unit, configured to inject the sealant into the main body of the accommodating chamber of the printing device.

[0042] Since the sealing glue printing device provided in this embodiment includes the printing device provided in Example 1, compared with the prior art where the sealing glue is scraped onto the display substrate through a screen printing process, the sealing frame provided in this embodiment The offset printing device does not need to use a scraper when printing the frame sealant, and will not cause wear to the mask plate, and will not affect the service life of the mask plate. The screen printing method in the prior art is open printing. With the evaporation of the solvent in the sealant, the viscosity of the sealant material incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com