Membrane coating multi-material photocuring 3D printing equipment and use method thereof

A 3D printing and multi-material technology, applied in the field of 3D printing, can solve the problems of low precision, small format, and large manufacturing format, and achieve the effect of high precision and large format

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a film-coated multi-material photocuring 3D printing device, such as figure 1 , 8 shown, including:

[0054] The optical system 1 is used to provide the radiation pattern of the cured printing liquid and monitor the projection accuracy;

[0055] printing platform 2, used to generate and carry objects to be printed;

[0056] The release film 3 is used to cooperate with the printing platform 2 to shape a layer thickness of the object to be printed;

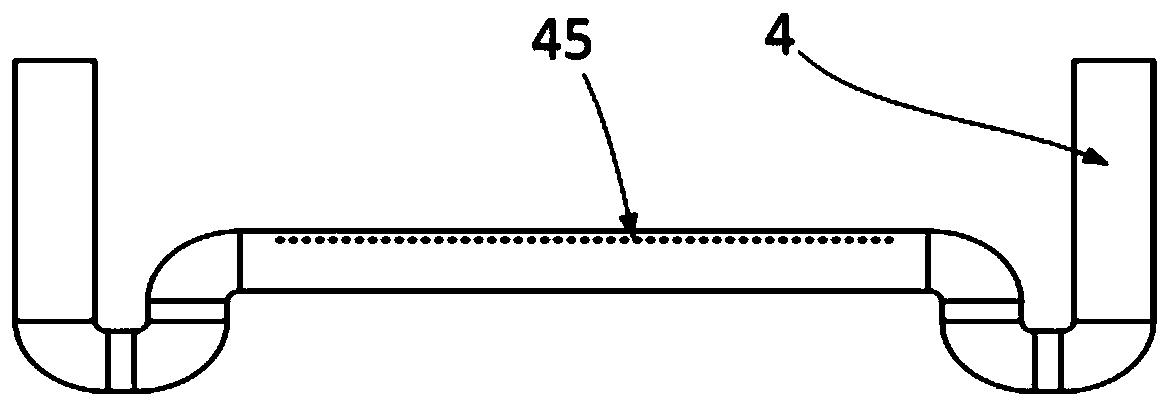

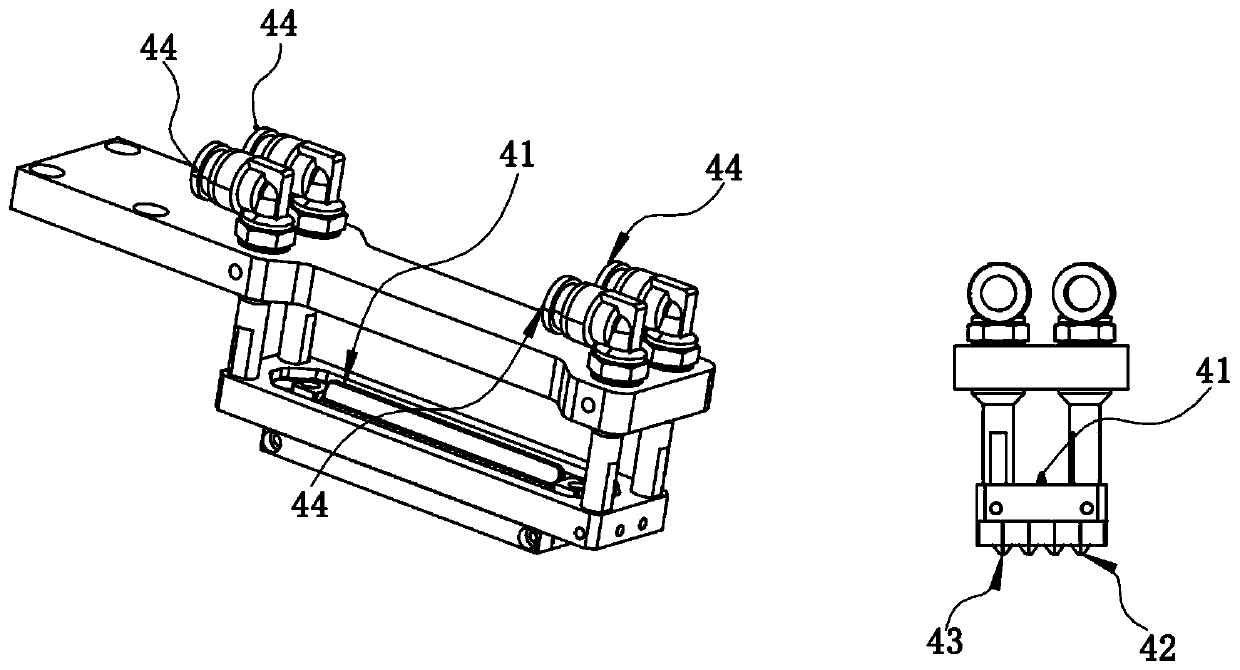

[0057] Coating scraper 4 is used to evenly coat different types of printing liquid between the release film 3 and the object to be printed, and the coating scraper 4 has holes or gaps that can discharge printing liquid; the coating scraper 4. Upward and / or downward air knives are provided to blow off the residual printing liquid on the release film 3 or the printed object;

[0058] The liquid storage and delivery assembly, including a storage device 61 and a delivery device 62 of printing liquid, ...

Embodiment 2

[0082] This embodiment provides a film-coated multi-material photocuring 3D printing method, specifically a method for generating a three-dimensional object from a fluid medium:

[0083] As an exemplary embodiment, the system can adopt:

[0084] 1. In this exemplary embodiment, a photosensitive resin curable by ultraviolet light in the 405nm band is selected, and the resin material can be a particle suspension;

[0085] 2. In this exemplary embodiment, a light source with a uniform illumination field at a wavelength of 405 nm, a DLP panel with a native resolution of 1920X1080, each pixel size of the DLP panel is about 7.6 μm X 7.6 μm, using optical elements, Includes a beam splitter for the microdisplay, a CCD camera for monitoring, and a projection lens to project the microdisplay image onto the coated side of the transparent film. In this exemplary embodiment, the magnification of the projection lens here is about 6.6, the image of each pixel is 50 μm X 50 μm, and the cover...

Embodiment 3

[0105] This embodiment provides a coating scraper 4, which can evenly coat the resin on the film or coat the resin on the object to be printed. The coating scraper of this embodiment is as follows: figure 2 As shown, it consists of a tube with openings to allow resin to be extruded along the span of the membrane or build platform. When the release film 3 or the printing platform 2 is pulled through the coating blade 4, the openings ensure that the resin is evenly coated. In a specific embodiment, the openings are coated in an array of holes 45, half of the holes form an angle of 65° with the tube plane, and the other half are perpendicular to the tube plane, and they are arranged alternately.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com