Aerobic fermentation treatment system

A treatment system, aerobic fermentation technology, applied in the direction of organic fertilizers, climate change adaptation, etc., can solve the problems of unstable fermentation, insufficient and incomplete fermentation, inconsistent feeding time, etc., to reduce environmental pollution and energy consumption , reduce the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

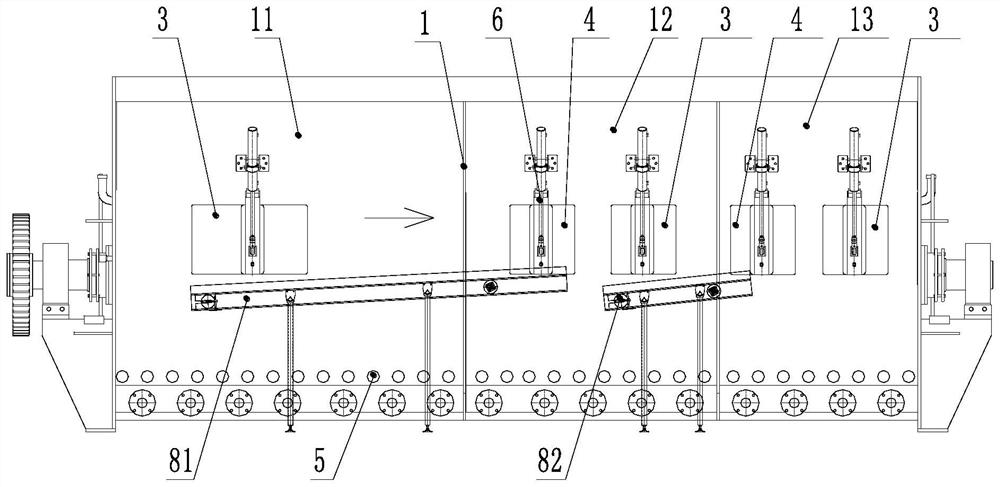

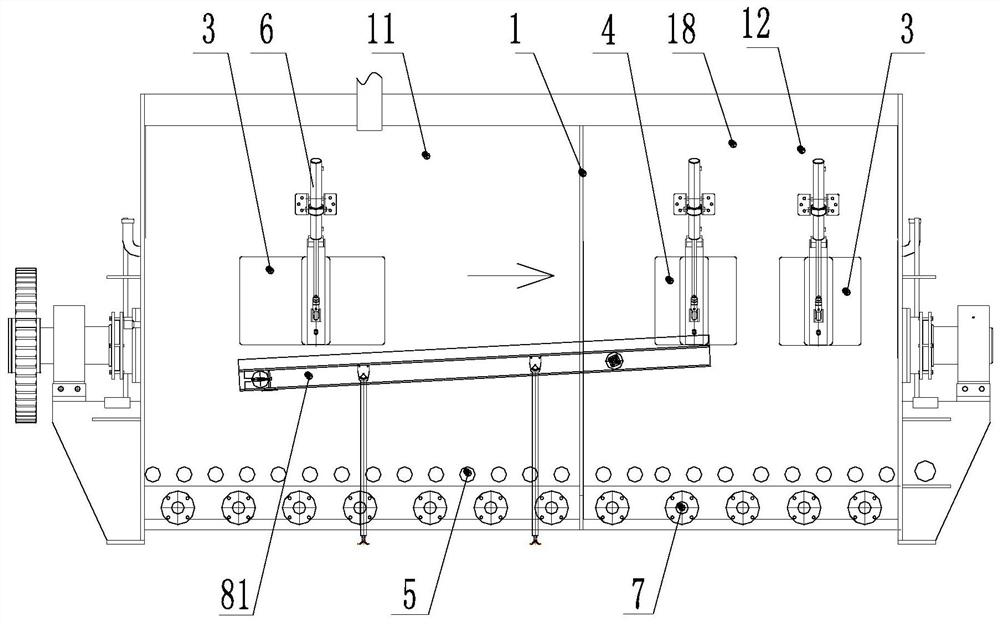

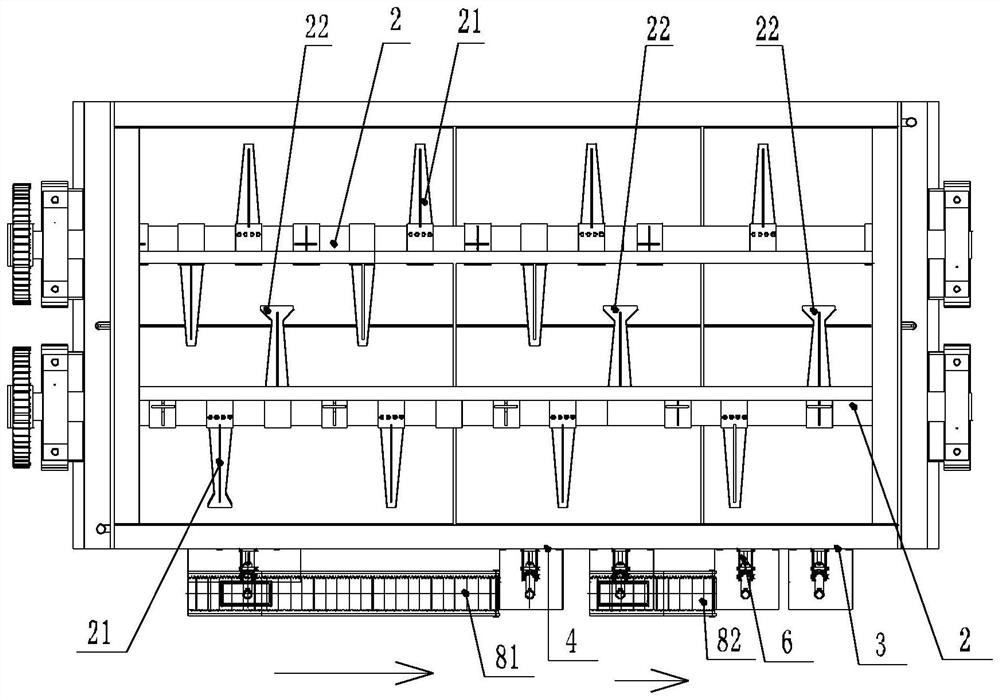

[0035] Such as Figure 1 to Figure 5 As shown, it is a schematic structural diagram of an aerobic fermentation treatment system of the present invention. The present invention includes a fermentation bin, a stirring shaft, a stirring paddle and a material conveying device for conveying materials. In this embodiment, the material conveying device adopts a belt conveyor, and the On the outside of the fermentation bin, the fermentation bin of the present invention is divided into at least two adjacent bin bodies, and each bin body is provided with a discharge port, a feed port, and a hydraulic pressure for opening and closing the feed port of the discharge port. Opening and closing doors (not shown) and independent heating systems; the bottom of each chamber is also equipped with an independent auxiliary electric heating system and an independent temperature control system, and the bottom of the entire fermentation chamber is provided with a cooling system for supplementing oxygen...

Embodiment 2

[0041] Such as Figure 1 to Figure 5 As shown, it is the aerobic fermentation treatment system of the present embodiment, and the same part as that of Embodiment 1 will not be described in detail in the present embodiment, such as Figure 1 to Figure 5 As shown, the material processed in this embodiment is kitchen waste, which is fed once a day at a fixed time, and the discharge cycle of each batch of materials is three days, so the fermentation bin of this embodiment is divided into three adjacent bins , according to the direction of material flow, the volume ratio of the bins decreases successively. In this embodiment, it is set to 12:10:8; the volume of the bins corresponds to the weight of the garbage processed in the fermentation bin; the three adjacent bins are in accordance with The material flow direction and temperature change are called in turn: the first warehouse body in the medium temperature section, the second warehouse body in the high temperature section, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com