Construction waste treatment device

A processing device, construction waste technology, applied in grain processing, mixer with rotating stirring device, transportation and packaging, etc., can solve problems such as inability to save resources, inability of crushing device to separate concrete and scrap metal, damage to crushing device, etc. Achieve low cost, meet social market demand, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

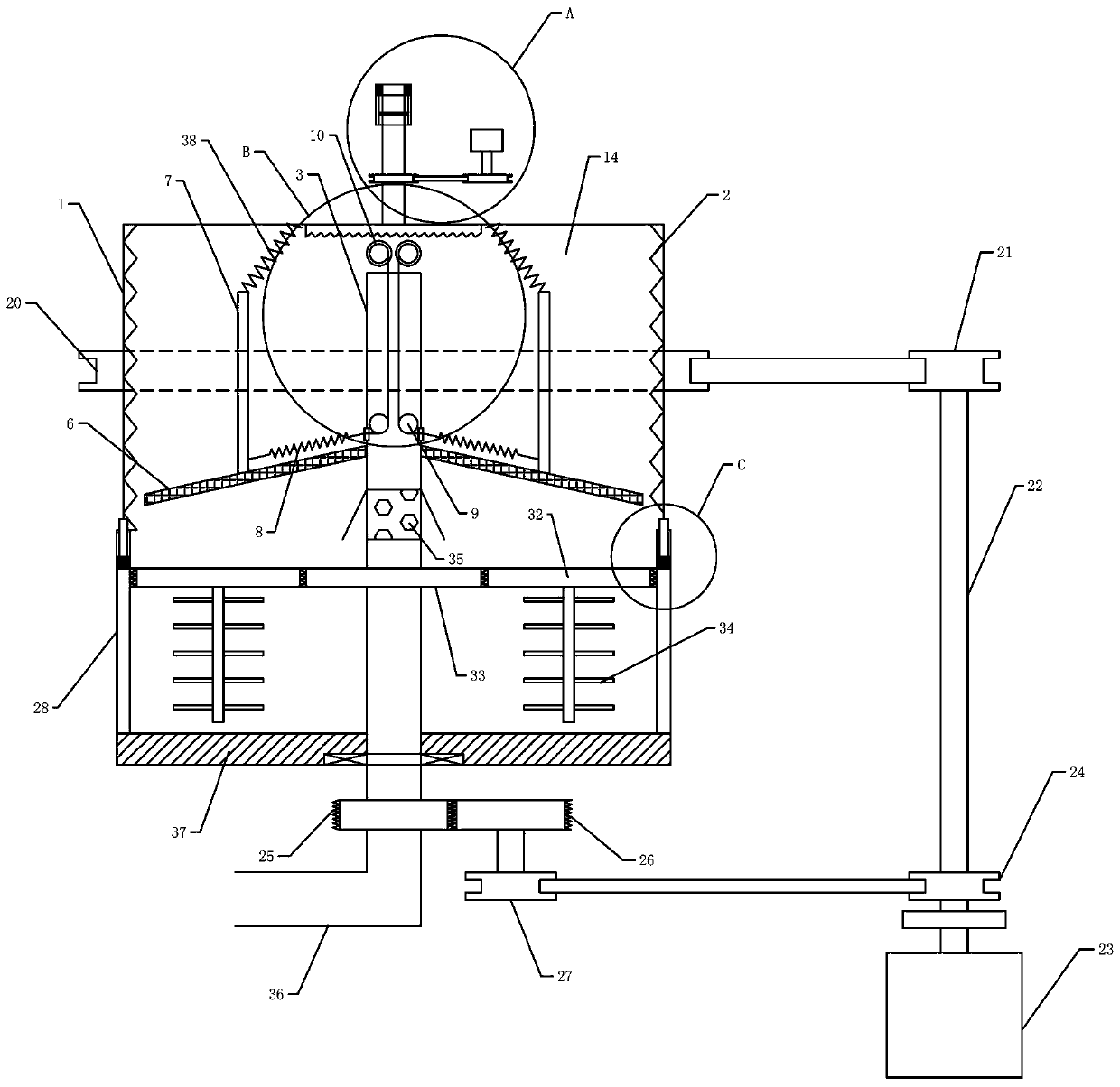

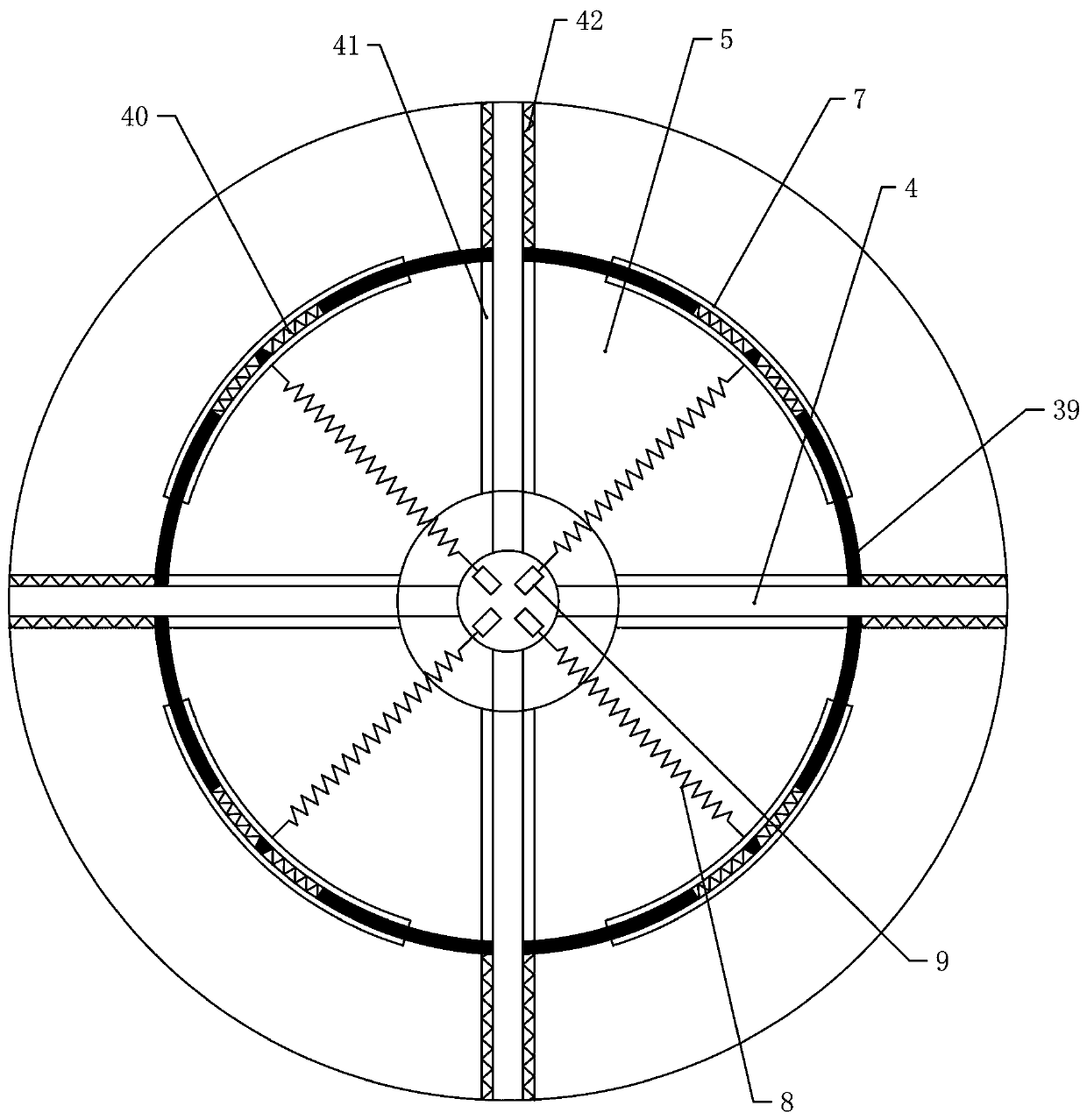

[0040] Embodiment 1. A construction waste treatment device, comprising an upper tank body 1, the upper end of which is a cavity inside the upper tank body 1, and a sawtooth-2 is provided on the inner side wall of the upper tank body 1, for crushing construction waste , the center of the upper tank body 1 is rotatably connected with a through-pipe 3, the inside of the through-pipe 3 is an opening at the upper end of the cavity, and the outer wall of the through-pipe 3 is fixed with a plurality of baffles 4 that are uniformly distributed around the through-pipe 3 around the circumference. The number of plates 4 is 4 or 6, and a crushing bin 5 is formed between a plurality of baffle plates 4, and an inclined filter screen 6 is fixed in the crushing bin 5, and the gap between the filter screen 6 and the sawtooth-2 is 3 cm, and the filter screen 6 From the through pipe 3 to the direction of the outer wall of the tank body 1, the edge of the filter screen 6 is provided with a slidewa...

Embodiment 2

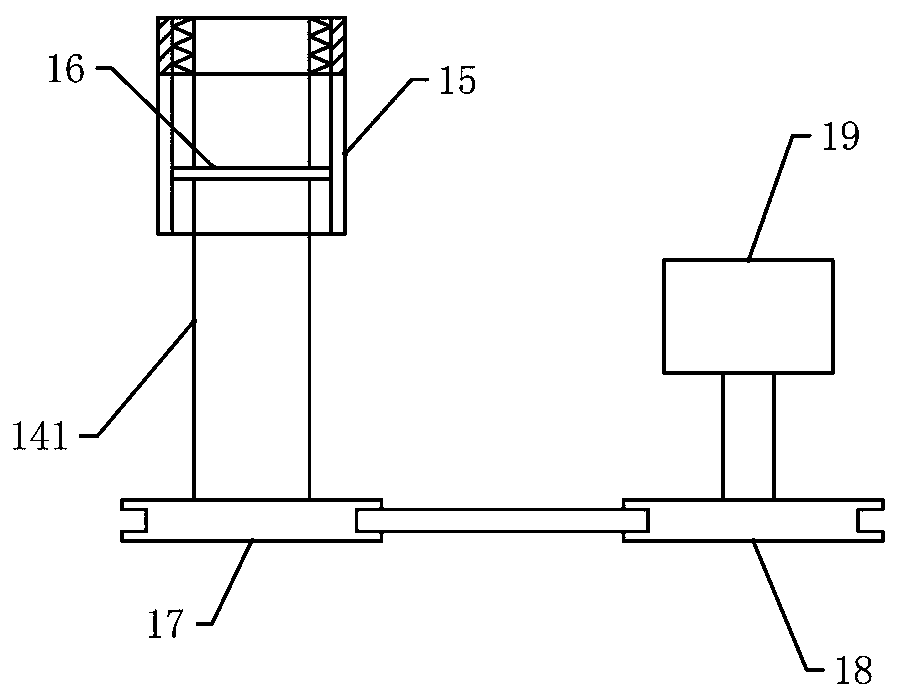

[0046] Embodiment 2, a lower tank body 28 is also provided below the upper tank body 1, and the upper end of the outer wall of the lower tank body 28 is provided with a draw-in groove 29, and an electromagnet 30 is embedded in the bottom of the draw-in groove 29, and the outer side of the upper tank body 1 The wall is rotated and installed in the draw-in groove 29. There are some internal teeth 31 at the upper end of the inner side wall of the lower tank body 28. The internal teeth 31 are meshed with a plurality of gears 3 32, and the gears 3 32 are meshed with gears 4 sleeved on the through pipe 3. 33, the lower end of the gear three 32 is equipped with a stirring shaft 34, and a water inlet 35 is provided on the through pipe 3 in the lower tank body 28, and a baffle plate inclined downward is installed at the water inlet 35, and the through pipe in the upper tank body 1 The through pipe 3 in the pipe 3 and the lower tank body 28 is not connected, and the middle is separated b...

Embodiment 3

[0049] Embodiment 3. The push plate 7 is connected to the upper end of the tank body 1 through a soft shielding curtain 38 to ensure that it can enter the crushing bin 5 when feeding. The two ends of the push plate 7 are stretchable stretch plates 39, Because the separated crushing bin 5 changes in an arc shape, the two ends of the push plate 7 are stretchable stretch plates 39, and the inboard of the stretch plate 39 is connected by a spring 2 40, and the push plate 7 needs to be stretched during the movement. Both sides of filter screen 6 are provided with slideways 41 for it, and the end of stretch plate 39 is connected with its outer side by spring three 42, while the pulley two 10 is wound with coil spring 43, which can well increase the return of push plate 7 force.

[0050] Specific usage method:

[0051] In order to better help the waste building to enter the crushing bin 5, the upper end of the push plate 7 and the upper tank body 1 is connected through a soft shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com