Method, device, vehicle and storage medium for determining clutch pressure

A technology of clutch pressure and determination method, which is applied to clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve problems such as cost increase, impact on the use efficiency of vehicle components, impact or flameout, etc., and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

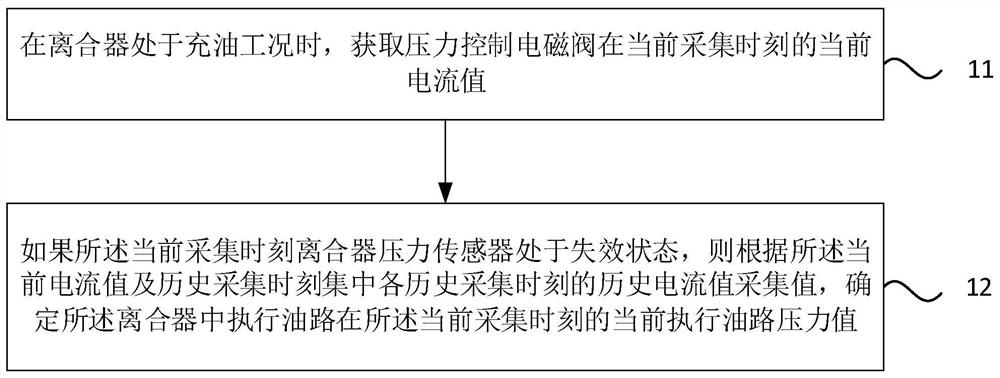

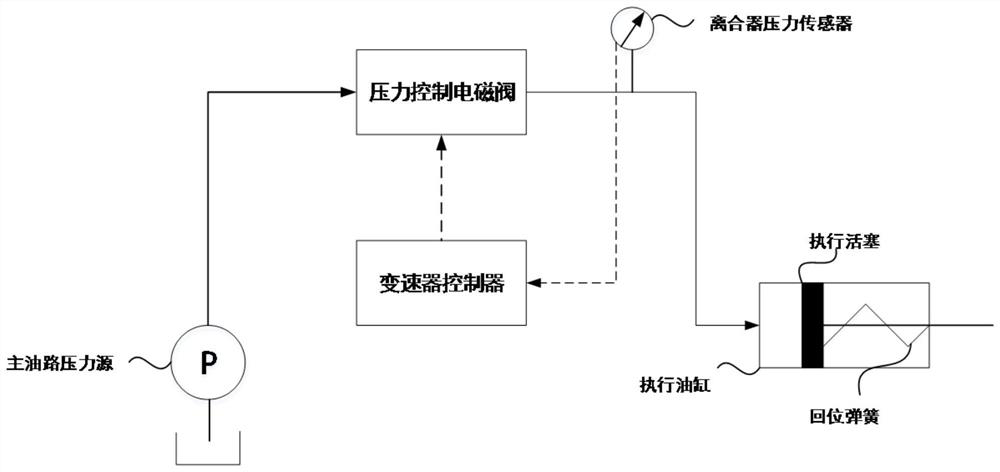

[0028] figure 1 It is a flow chart of a method for determining clutch pressure provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation where the pressure sensor in the wet clutch pressure control system fails to estimate the oil circuit pressure. This method can be determined by the clutch pressure Determining means, the clutch pressure determining means can be implemented by software and / or hardware, the clutch pressure determining means can be configured on the computing device, for example, figure 2 It is a structural schematic diagram of a wet clutch pressure control system, which specifically includes the following steps:

[0029] Step 11. Acquire the current current value of the pressure control solenoid valve at the current collection time when the clutch is in the oil-filled working condition.

[0030] Among them, the oil-filled working condition can be understood as the main oil circuit pressure source controls the hydraulic...

Embodiment 2

[0041] image 3 It is a flowchart of a method for determining clutch pressure provided by Embodiment 2 of the present invention. The technical solution of this embodiment is further refined on the basis of the above-mentioned technical solution, specifically including the following steps:

[0042] Step 21. Acquire the current current value of the pressure control solenoid valve at the current acquisition time when the clutch is in the oil-filling condition.

[0043] Step 22. When the clutch pressure sensor was in the valid state at the previous collection time, determine the working state of the clutch pressure sensor at the current collection time, and the working state is the valid state or the invalid state.

[0044] specific, Figure 4 A flow chart for determining the working state of the clutch pressure sensor at the current acquisition time is provided, which specifically includes the following steps:

[0045] Step 221. Obtain the current pressure value of the pressur...

Embodiment 3

[0058] Figure 5 It is a flow chart of a method for determining clutch pressure provided by Embodiment 3 of the present invention. The technical solution of this embodiment is further refined on the basis of the above-mentioned technical solution, specifically including the following steps:

[0059] Step 31. Acquire the current current value of the pressure control solenoid valve at the current acquisition time when the clutch is in the oil-filling condition.

[0060] Step 32. If the clutch pressure sensor is in failure state at the current collection time, acquire the historical current value and the corresponding historical execution oil circuit pressure value at each historical collection time.

[0061] Among them, the historical current value can be understood as the current given by the pressure control solenoid valve at the historical collection time, and the historical execution oil circuit pressure value can be understood as the pressure value in the execution cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com