An unmanned mining vehicle lift control system, method and mining vehicle

An unmanned driving and control system technology, applied in the direction of freight vehicles, motor vehicles, loading and unloading vehicles, etc., can solve problems such as danger, cab being pushed up, and overturning accidents, etc., to improve work efficiency and operation. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

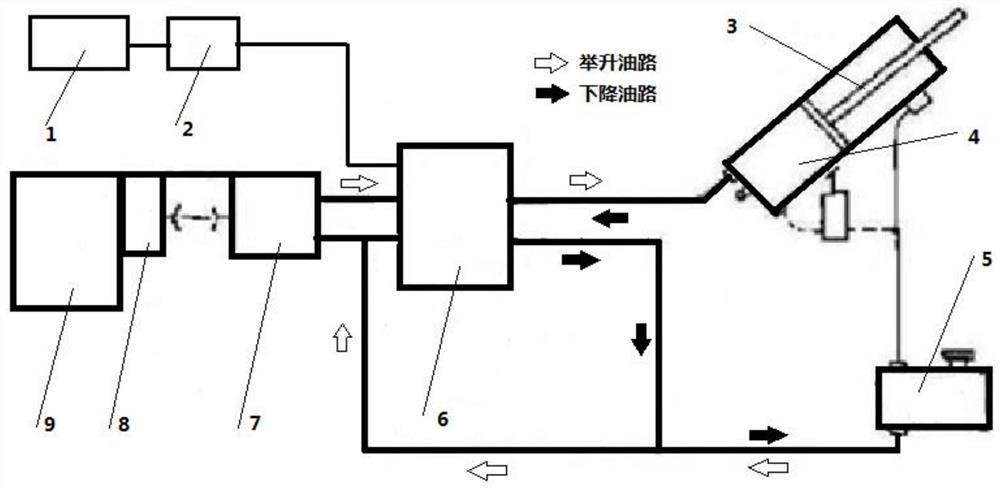

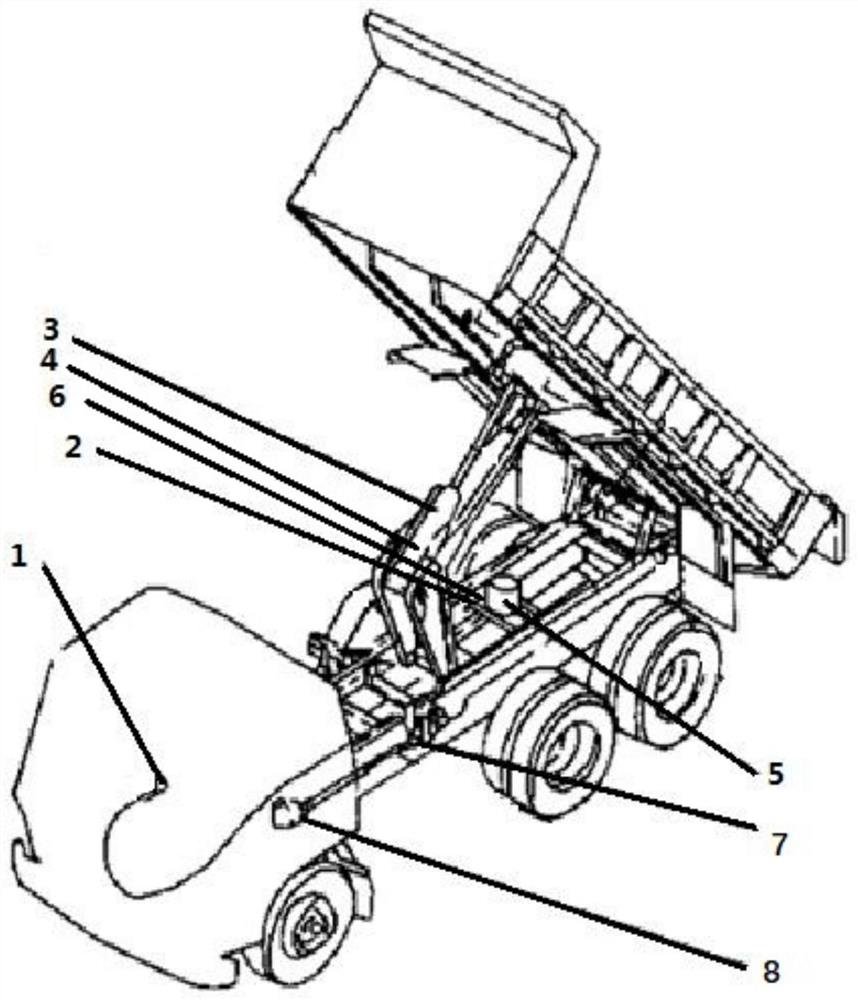

[0018] like figure 1 , 2 As shown in the figure, an unmanned mining vehicle lift control system includes a body attitude sensor 1, a reversing valve controller 3, a reversing valve 6, a piston rod 3, a hydraulic cylinder 4, a fuel tank 5, and a gear pump 7 and PTO 8;

[0019] The vehicle body attitude sensor 1 is located in the cab and is used to measure the attitude of the vehicle body;

[0020] The reversing valve controller 2 is located on the outside of the frame longitudinal beam, one end of which is connected to the vehicle body attitude sensor 1, and the other end is connected to the reversing valve 6, and receives the information of the vehicle body attitude sensor 1 for controlling the switch. To the working position of valve 6, the working position includes lifting and lowering;

[0021] The reversing valve 6 is located outside the longitudinal beam of the frame, and is used to receive information from the reversing valve controller 2, and based on the information...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap