Method for improving orientation degree and conductivity of carbon nanotube fiber

A technology of carbon nanotube fiber and degree of orientation, which is applied in the direction of carbon fiber, fiber treatment, fiber chemical characteristics, etc., can solve the problems of fiber brittleness and no improvement of fiber orientation degree, and achieve the improvement of orientation degree and density, light weight and hardness big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

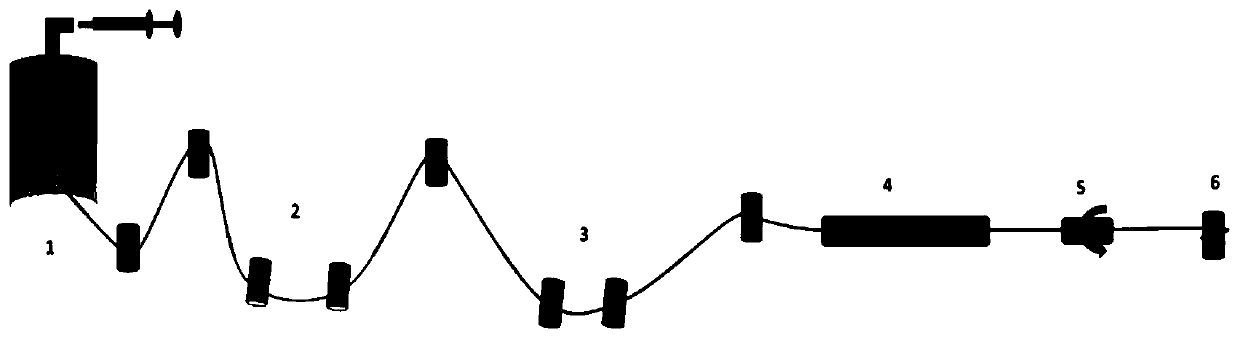

Method used

Image

Examples

Embodiment 1

[0041]Continuous primary carbon nanotube fibers were prepared by floating catalytic chemical vapor deposition. In the tube furnace, hydrogen and argon are used as the carrier gas, ethanol is used as the carbon source, ferrocene and thiophene are dissolved in ethanol as catalysts, and continuously injected into the vertical high-temperature tube furnace to form carbon nanotube airgel, and Draw out under the furnace to shrink through a water tank, then further shrink through acetone, heat and dry to obtain carbon nanotube strips. Wherein the gap size between carbon nanotubes is 10-100nm, the content of ferrocene is 1.2wt%, the content of thiophene is 0.6wt%, and the injection rate of ethanol is controlled at 5mL h -1 , hydrogen flow at 300mL·min -1 , argon gas flow at 500mL·min -1 , the temperature of the tube furnace is 1200°C.

[0042] The primary carbon nanotube fibers were immersed in a 5wt% chlorosulfonic acid solution for a swelling time of 100 s, and then properly stre...

Embodiment 2

[0047] Continuous primary carbon nanotube fibers were prepared by floating catalytic chemical vapor deposition. In the tube furnace, hydrogen and argon are used as the carrier gas, ethanol is used as the carbon source, ferrocene and thiophene are dissolved in ethanol as catalysts, and continuously injected into the vertical high-temperature tube furnace to form carbon nanotube airgel, and Draw out under the furnace to shrink through a water tank, then further shrink through acetone, heat and dry to obtain carbon nanotube strips. Wherein the gap size between carbon nanotubes is 10-100nm, the content of ferrocene is 1.2wt%, the content of thiophene is 0.6wt%, and the injection rate of ethanol is controlled at 5mL h -1 , hydrogen flow at 300mL·min -1 , argon gas flow at 500mL·min -1 , the temperature of the tube furnace is 1200°C.

[0048] The primary carbon nanotube fibers were immersed in 15wt% chlorosulfonic acid solution, the swelling time was 10s, and then properly stretc...

Embodiment 3

[0053] Continuous primary carbon nanotube fibers were prepared by floating catalytic chemical vapor deposition. In the tube furnace, hydrogen and argon are used as the carrier gas, ethanol is used as the carbon source, ferrocene and thiophene are dissolved in ethanol as catalysts, and continuously injected into the vertical high-temperature tube furnace to form carbon nanotube airgel, and Draw out under the furnace to shrink through a water tank, then further shrink through acetone, heat and dry to obtain carbon nanotube strips. Wherein the gap size between carbon nanotubes is 10-100nm, the content of ferrocene is 1.2wt%, the content of thiophene is 0.6wt%, and the injection rate of ethanol is controlled at 5mL h -1 , hydrogen flow at 300mL·min -1 , argon gas flow at 500mL·min -1 , the temperature of the tube furnace is 1200°C.

[0054] The primary carbon nanotube fibers were immersed in a 10wt% chlorosulfonic acid solution, the expansion time was 20s, and then properly str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com