Viscosity reducer for ultra-high performance concrete and its preparation method and application

An ultra-high-performance, viscosity-reducing agent technology, applied in the field of concrete admixtures, can solve the problems of restricting the promotion and application of high-strength and ultra-high-strength concrete, poor workability, high viscosity, etc., to achieve low production costs, reduce viscosity, and increase mutual repulsion force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

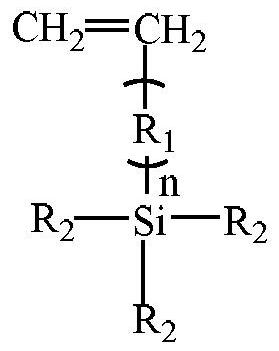

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of ultra-high performance concrete viscosity reducer of the present embodiment, comprises the following steps:

[0040]Step 1: Add 10g of silica fume (average particle size 0.5μm) into 100g of water and ultrasonically disperse for 15 minutes (in other embodiments, the same or similar technical effect can be achieved if the dispersion time is 10-25 minutes), move to magnetic stirring and add dropwise 5g of vinyltriethoxysilane (VTEO) was dripped for 1 hour, and the reaction was continued for 2 hours to obtain a precursor solution.

[0041] Step 2: Add 137g of isopentenol polyoxyethylene ether fully dissolved in water to the precursor solution, pour 1.8g of hydrogen peroxide, stir for 1-2min, and gradually add a solution of 15.2g of acrylic acid and 30g of water, 0.3 A solution of 1 g of ascorbic acid, 0.76 g of mercaptothiol and 50 g of water was dripped for 2.5 hours, then reacted for 2 hours after the dropwise addition, and neutralized with...

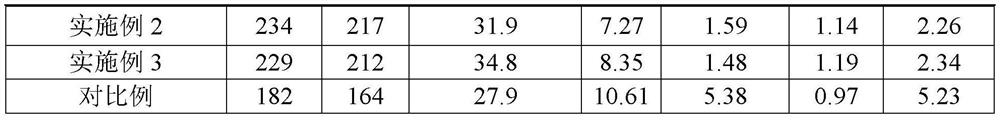

Embodiment 2

[0043] A kind of preparation method of ultra-high performance concrete viscosity reducer of the present embodiment, comprises the following steps:

[0044] Step 1: Add 15g of fly ash (average particle size 5.6μm) into 120g of water and ultrasonically disperse for 25min, move to magnetic stirring and add 5g of γ-methacryloxypropyltrimethoxysilane (KH570) dropwise for 1h , and continue to react for 1 h to obtain a precursor solution.

[0045] Step 2: Add 140g of allyl alcohol polyoxyethylene ether fully dissolved in water to the precursor solution, pour 1.8g of hydrogen peroxide, stir for 1-2min, and gradually add a solution of 20g of methyl methacrylate and 50g of water at the same time , 0.5g of ascorbic acid, 0.9g of thioglycolic acid and 50g of water, drop it for 2 hours, react for 1.5 hours after the dropwise addition, neutralize it with sodium hydroxide until the pH is 7, and obtain the viscosity reducer for ultra-high performance concrete.

Embodiment 3

[0047] A kind of preparation method of ultra-high performance concrete viscosity reducer of the present embodiment, comprises the following steps:

[0048] Step 1: Add 20g of silica fume (average particle size 0.5μm) into 150g of water for ultrasonic dispersion for 20min, move to magnetic stirring and add dropwise 5g of γ-methacryloxypropyltrimethoxysilane (KH570) and 5g of vinyl trimethoxysilane The mixture of ethoxysilane (VTEO) was dropped after 2 hours, and the reaction was continued for 1 hour to obtain a precursor solution.

[0049] Step 2: Add 170g of allyl alcohol polyoxyethylene ether fully dissolved in water to the precursor solution, pour 1.8g of hydrogen peroxide, stir for 1-2min, and gradually add a solution of 30g of maleic anhydride and 70g of water, 0.5 A solution of 1 g of ascorbic acid, 0.7 g of mercaptopropionic acid and 50 g of water was dripped for 2.5 hours, then reacted for 1 hour after the dropwise addition, and neutralized with sodium hydroxide to a pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com