Mineral soil conditioner and preparation method thereof

A soil conditioner and mineral technology, used in fertilizer mixtures, solid/semi-solid fertilizers, agriculture, etc., can solve the problems of inconvenience for plants to provide nutrients, slow plant growth, and large loss of soil fertility, and improve soil fertility. The effect of permeability, reducing soil fertility loss, and promoting tree growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a technical solution: a mineral soil conditioner and a preparation method thereof, comprising oyster shells, limestone, dolomite, bentonite, peat, peat cyanite, vermiculite, diatomaceous earth, zeolite, sepiolite, water-absorbing Stone, calcium carbonate, sodium alginate and organosilicon fertilizer, the proportion of which is formulated by weight: the proportion of oyster shell is set to 5-15%, the proportion of limestone is set to 10-20%, and the proportion of dolomite is set to 1-5% , the proportion of bentonite is set to 5-20%, the proportion of peat is set to 3-7%, the proportion of peat cyanite is set to 2-7%, the proportion of vermiculite is set to 3-5%, and the proportion of diatomite is Set it to 5-10%, the proportion of zeolite is set to 5-15%, the proportion of sepiolite is set to 2-5%, the proportion of water-absorbing stone is set to 7-25%, and the proportion of calcium carbonate is set to 8-18% , the proportion of sodium alginate is ...

example 1

[0033] The invention provides a technical solution: including zeolite, bentonite, vermiculite, coal fly ash, perlite, sepiolite, seaweed extract, humic acid fertilizer, alkaline silicate and synthetic foam resin, wherein the ratio is prepared by weight : 6 parts of zeolite, 8 parts of bentonite, 4 parts of vermiculite, 2 parts of coal fly ash, 12 parts of perlite, 7 parts of sepiolite, 10 parts of seaweed extract, 15 parts of humic acid fertilizer, 12 parts of alkaline silicate , 10 parts of synthetic foam resin.

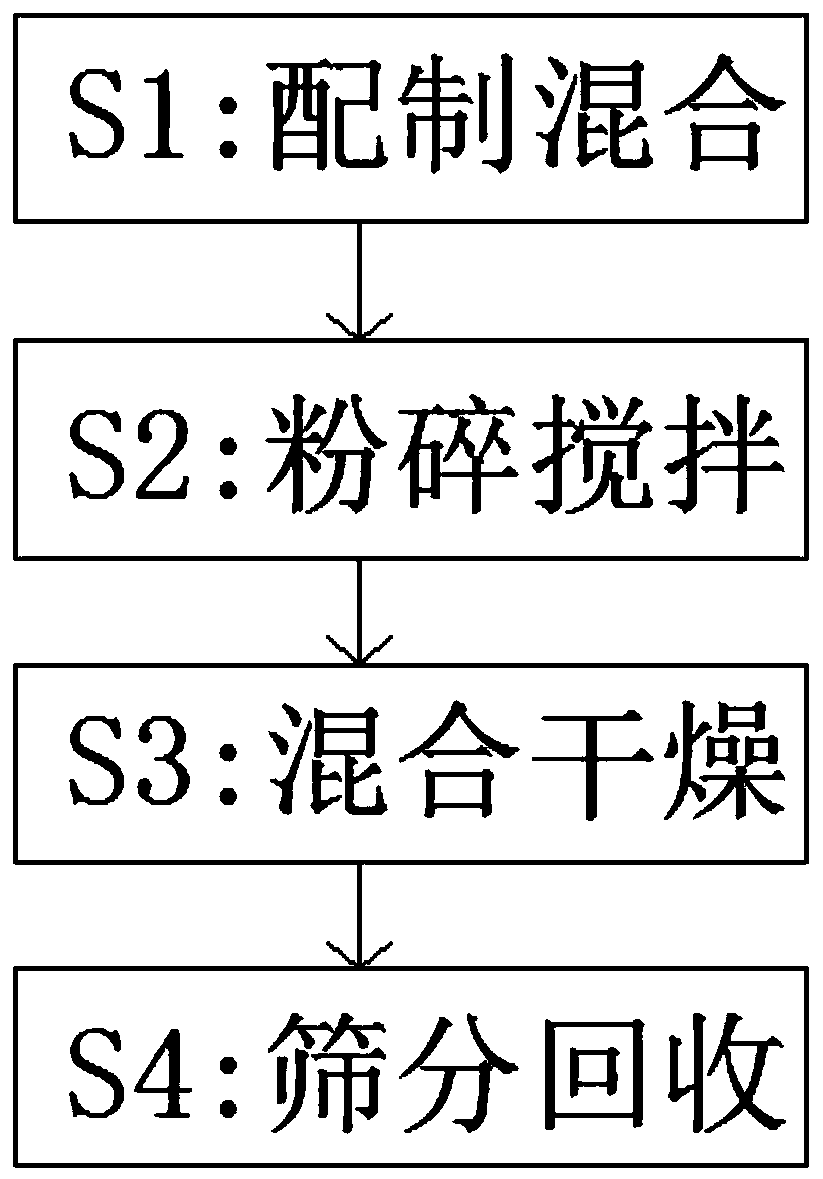

[0034] The production steps include the following:

[0035] S1, Preparation and mixing: Precisely prepare various minerals such as zeolite, bentonite, vermiculite, coal fly ash, perlite and sepiolite in proportion, and mix them into the crushing equipment;

[0036] S2, crushing and stirring: the various mineral soils are uniformly crushed and ground by a crusher, and the crushing time is controlled at about 35 minutes;

[0037] S3, mixing and drying: transfer the ...

example 2

[0045] The invention provides a technical solution: including zeolite, bentonite, vermiculite, coal fly ash, perlite, sepiolite, seaweed extract, humic acid fertilizer, alkaline silicate and synthetic foam resin, wherein the ratio is prepared by weight : 8 parts of zeolite, 12 parts of bentonite, 4 parts of vermiculite, 2 parts of coal fly ash, 13 parts of perlite, 8 parts of sepiolite, 15 parts of seaweed extract, 18 parts of humic acid fertilizer, 6 parts of alkaline silicate , 3 parts of synthetic foam resin.

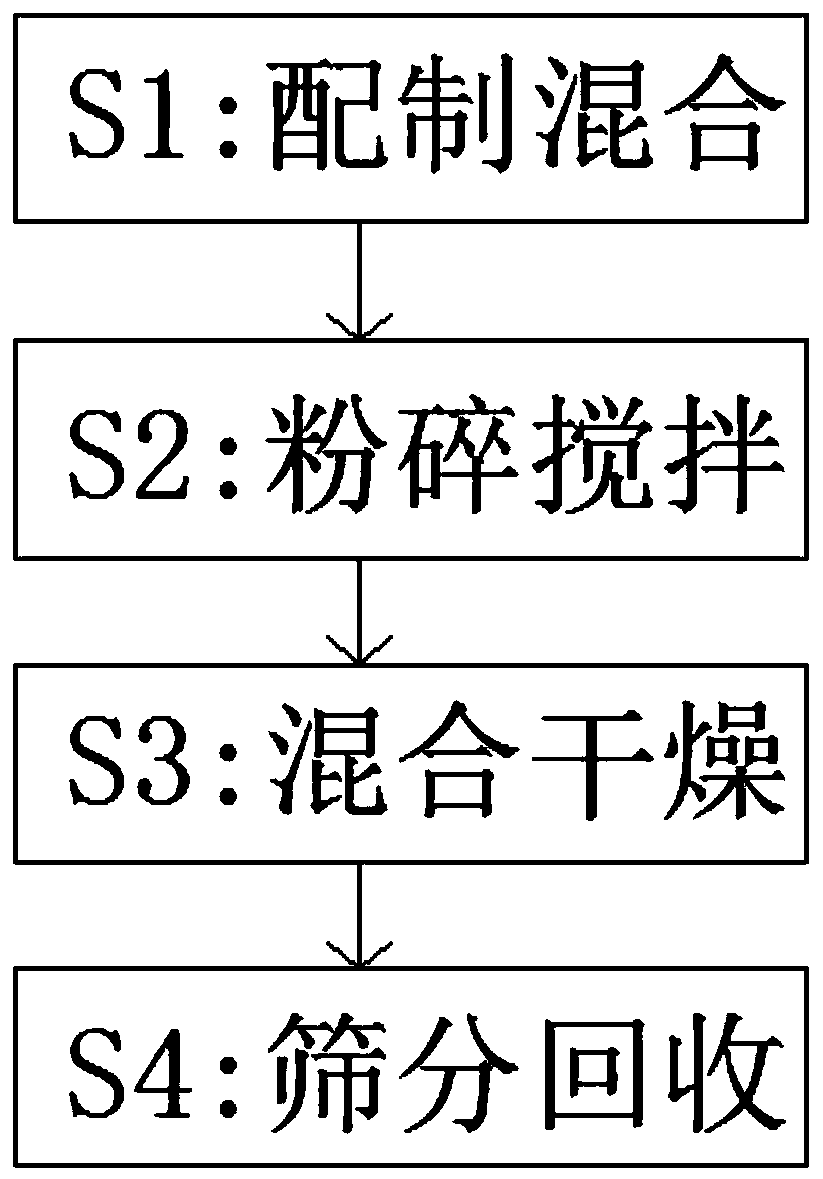

[0046] The production steps include the following:

[0047] S1, Preparation and mixing: Precisely prepare various minerals such as zeolite, bentonite, vermiculite, coal fly ash, perlite and sepiolite in proportion, and mix them into the crushing equipment;

[0048] S2, crushing and stirring: the various mineral soils are uniformly crushed and ground by a crusher, and the crushing time is controlled at about 35 minutes;

[0049] S3, mixing and drying: transfer the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com