Data control machine tool health monitoring system

A health monitoring system and data control technology, applied in the field of numerical control, can solve problems such as high cost, difficult installation, and no wireless communication module combined with the health monitoring system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

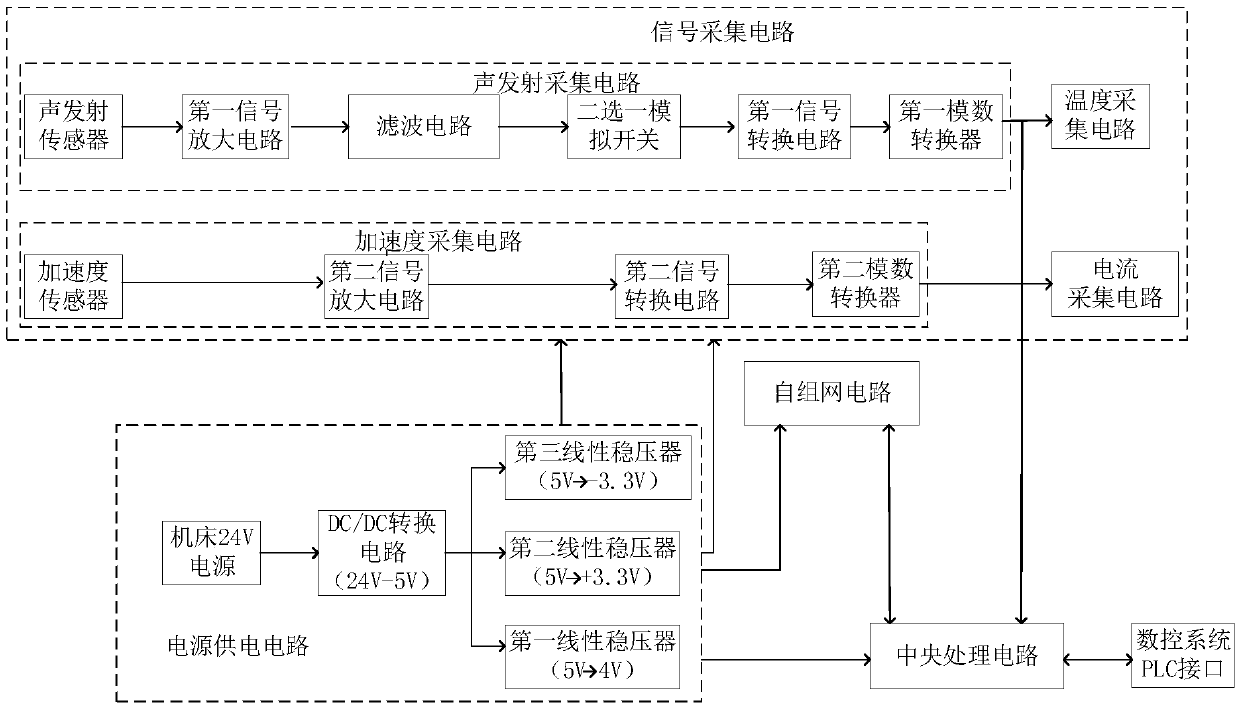

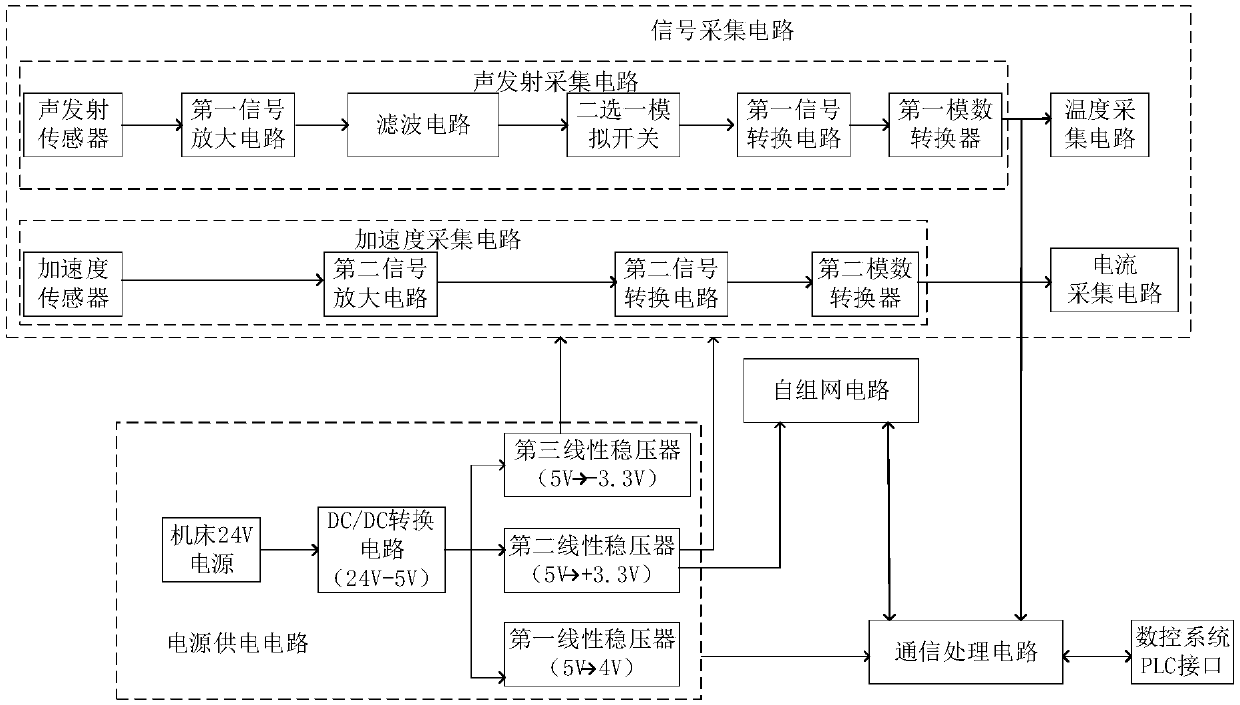

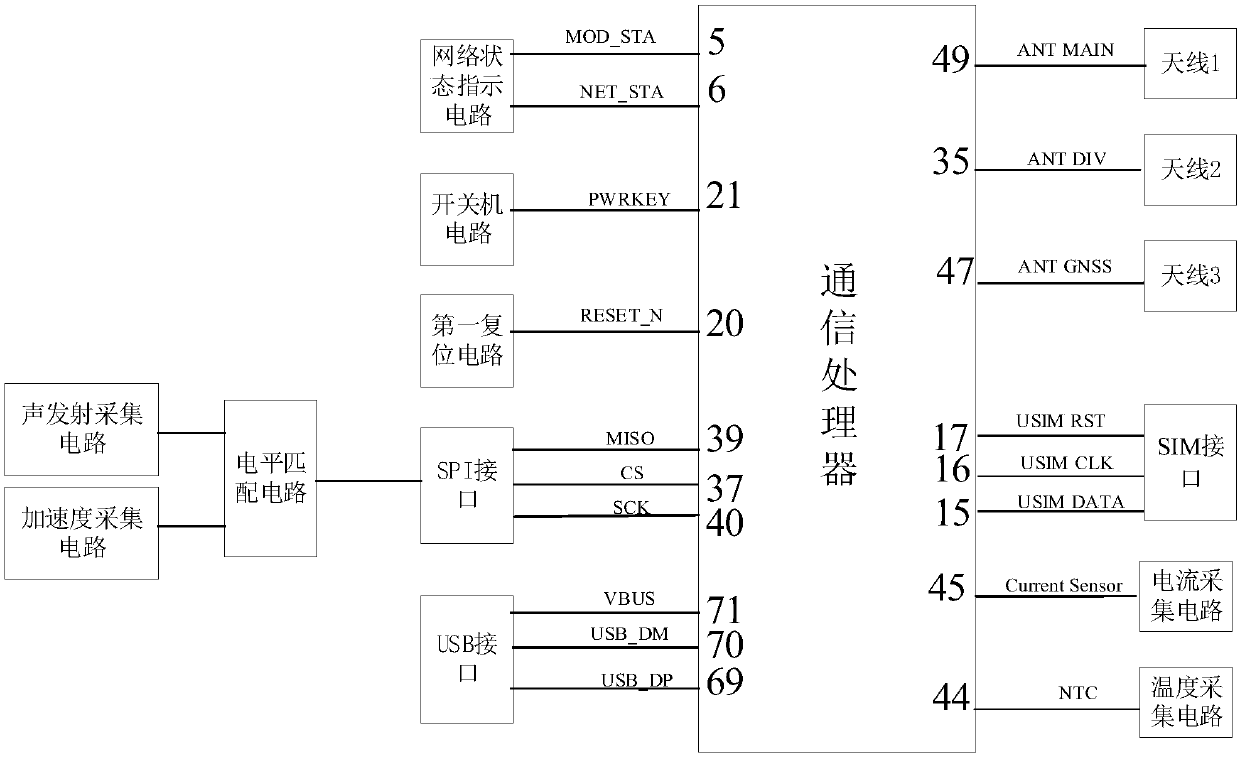

[0044] Such as figure 1 As shown, a data control machine tool health monitoring system, including: power supply circuit, signal acquisition circuit, CNC system PLC interface, ad hoc network circuit, central processing circuit, the power supply circuit, signal acquisition circuit, CNC system PLC interface and the self-organizing network circuit are all connected with the central processing circuit. The central processing circuit is a communication processing circuit.

[0045] More specifically as figure 2 As shown, the power supply circuit includes the machine tool 24V power supply, DC / DC conversion circuit, the first linear voltage regulator, the second linear voltage regulator, the third linear voltage regulator, the machine tool 24V power supply and the input end of the DC / DC conversion circuit connection, the output end of the DC / DC conversion circuit is connected to the input end of the input end of the first linear voltage regulator, the input end of the second linear ...

Embodiment 2

[0067] Embodiment 2: The difference from Embodiment 1 is that the central processing unit selects an ARM processing circuit.

[0068] Such as Figure 10 As shown, a health monitoring system of a numerically controlled machine tool, in this embodiment, there is no need to connect the first linear voltage regulator to supply power to the ARM processing circuit. The ARM processing circuit includes an ARM processor, a memory, and a second reset circuit. The second reset circuit is connected to the ARM processor, and the ARM processor is connected to the memory.

[0069] The power supply circuit, the signal acquisition circuit, the PLC interface of the numerical control system, and the ad hoc network circuit are just that each circuit is connected to the ARM processing circuit. Because the chip changes, the ARM selects the STM32 processor in this embodiment.

[0070] Such as Figure 11 As shown, pins 1, 41, and 42 of the ARM processor are respectively connected to pins 3, 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com