Wall painting equipment in the field of construction machinery for leveling

A technology of construction machinery and equipment, applied in the direction of construction and building structure, etc., can solve the problems of wall cavity, increased construction workload, brush material falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

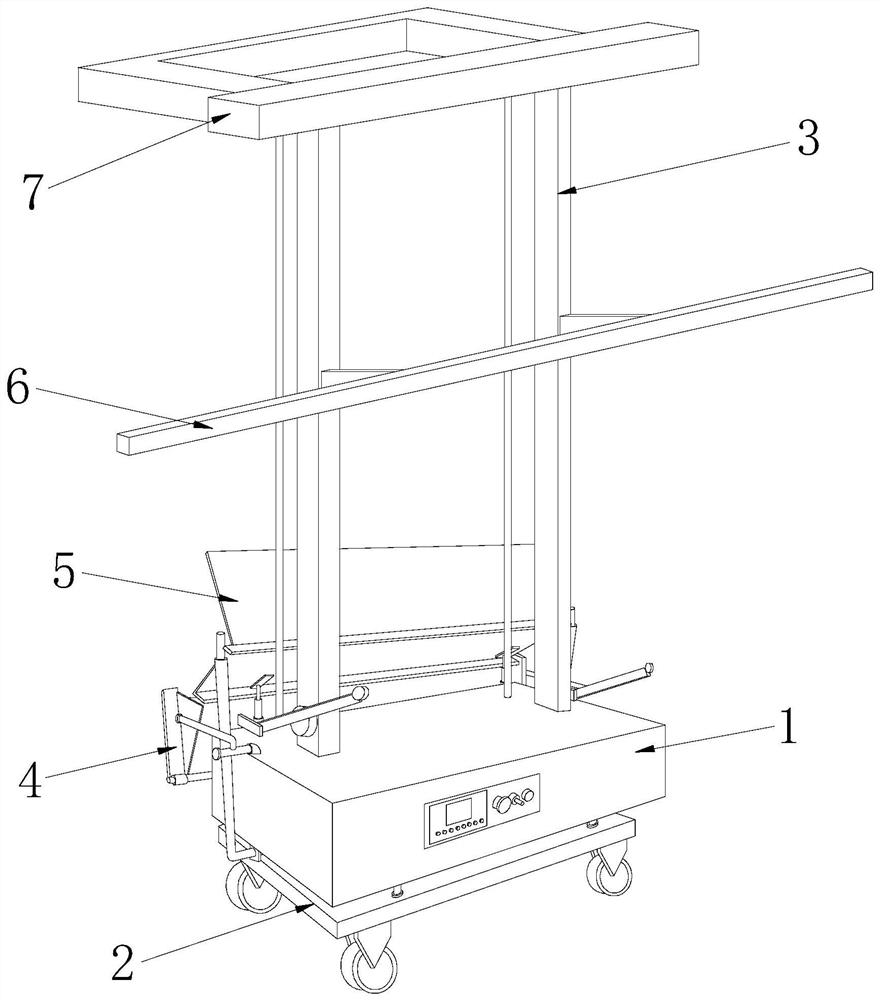

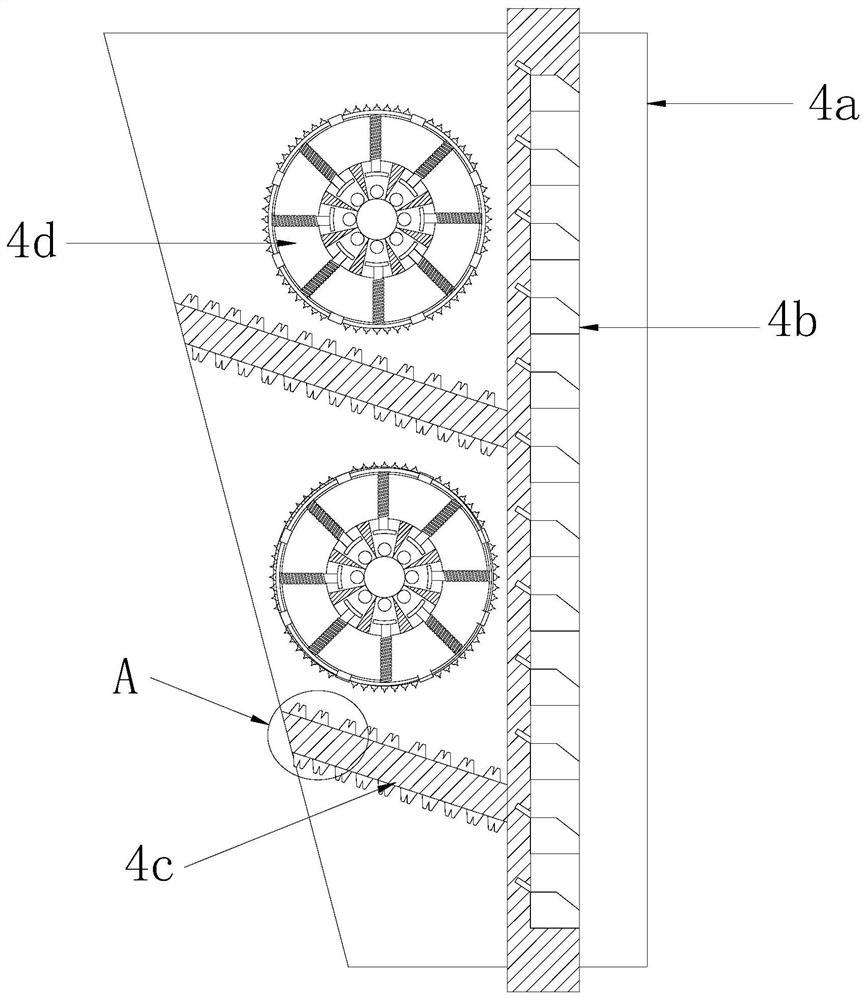

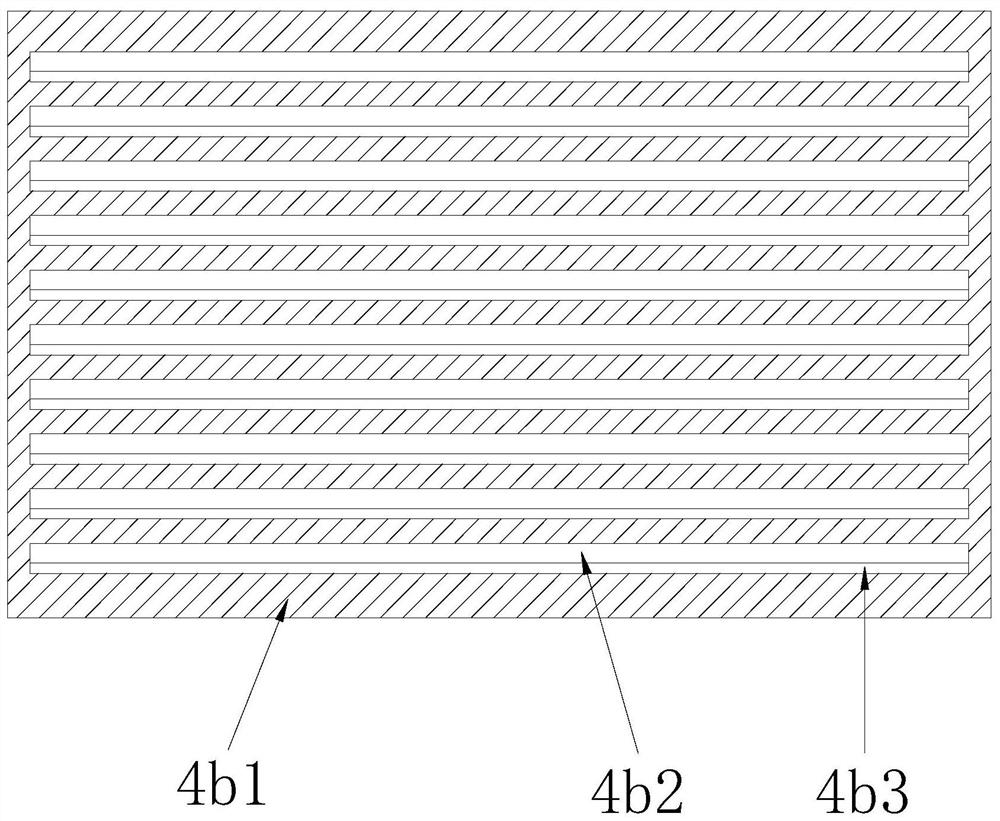

[0026] Such as Figure 1-Figure 3 As shown, the present invention provides a technical scheme of wall painting equipment in the field of construction machinery for shunting and leveling:

[0027] Such as Figure 1-Figure 2 As shown, a wall painting equipment in the field of construction machinery for shunting and leveling, its structure includes a main body 1, a mobile chassis 2, a pole 3, a leveling device 4, a front axle shield 5, a hand-held square tube 6, and a sky beam 7 , the mobile chassis 2 is installed on the lower surface of the equipment main body 1 and connected by electric welding, and two vertical poles 3 are installed on the upper surface of the equipment main body 1 and connected vertically by electric welding. The leveling device 4 Installed on the rear side surface of the equipment main body 1 and connected by electric welding, the front axle shield 5 is installed on the top of the leveling device 4 and connected by electric welding, and the hand-held square...

no. 2 example

[0033] Such as figure 1 , figure 2 , Figure 4 , Figure 5 As shown, the present invention provides a technical scheme of wall painting equipment in the field of construction machinery for shunting and leveling:

[0034] Such as Figure 1-Figure 2As shown, a wall painting equipment in the field of construction machinery for shunting and leveling, its structure includes a main body 1, a mobile chassis 2, a pole 3, a leveling device 4, a front axle shield 5, a hand-held square tube 6, and a sky beam 7 , the mobile chassis 2 is installed on the lower surface of the equipment main body 1 and connected by electric welding, and two vertical poles 3 are installed on the upper surface of the equipment main body 1 and connected vertically by electric welding. The leveling device 4 Installed on the rear side surface of the equipment main body 1 and connected by electric welding, the front axle shield 5 is installed on the top of the leveling device 4 and connected by electric weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com