Assembly type tailing dam and construction method thereof

A tailings dam and prefabricated technology, which is applied in the field of mine engineering, can solve the problems of easy dam failure, high soaking line, poor permeability, etc., and achieve the effects of reduced probability of dam failure, large storage capacity, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

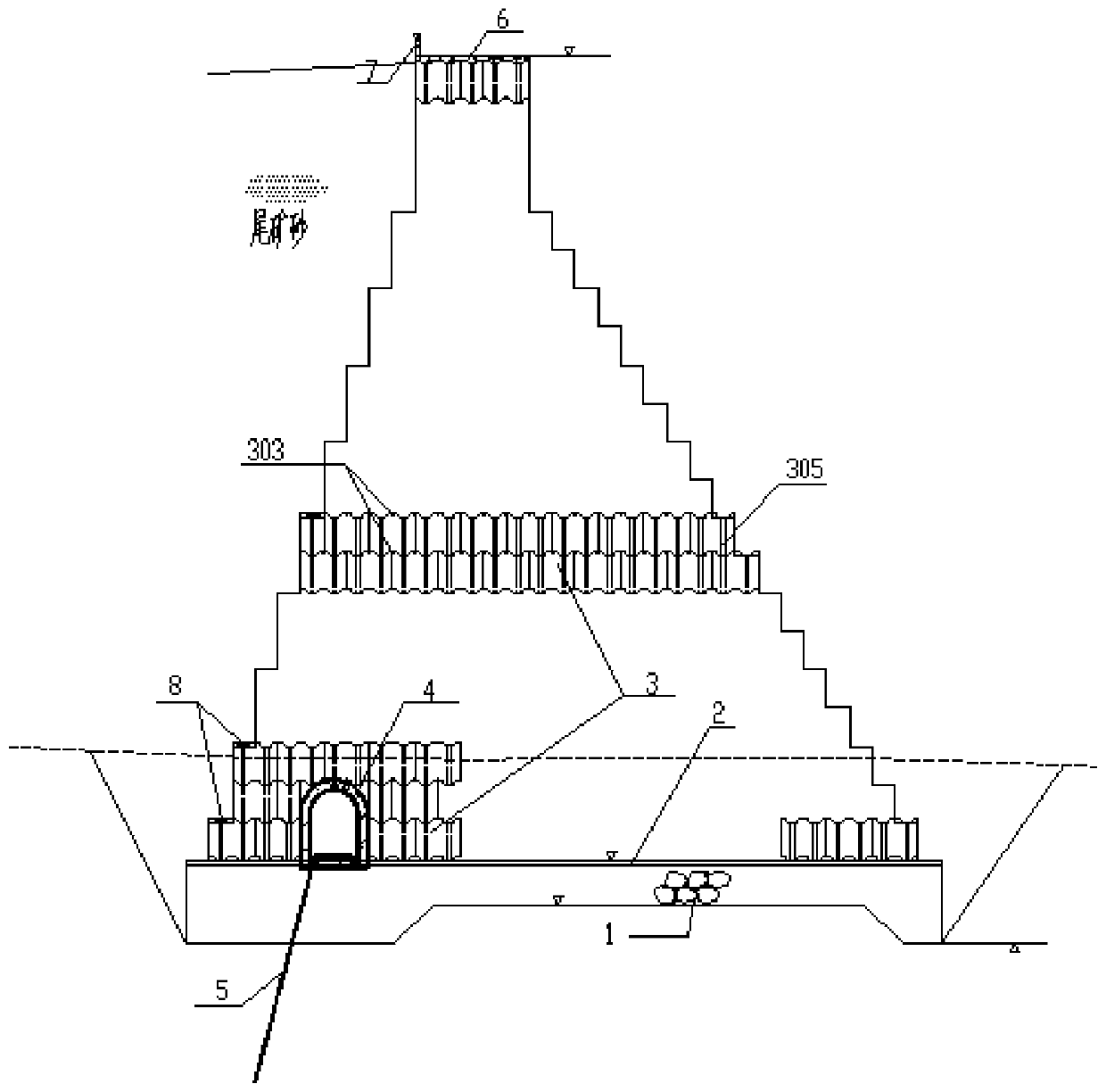

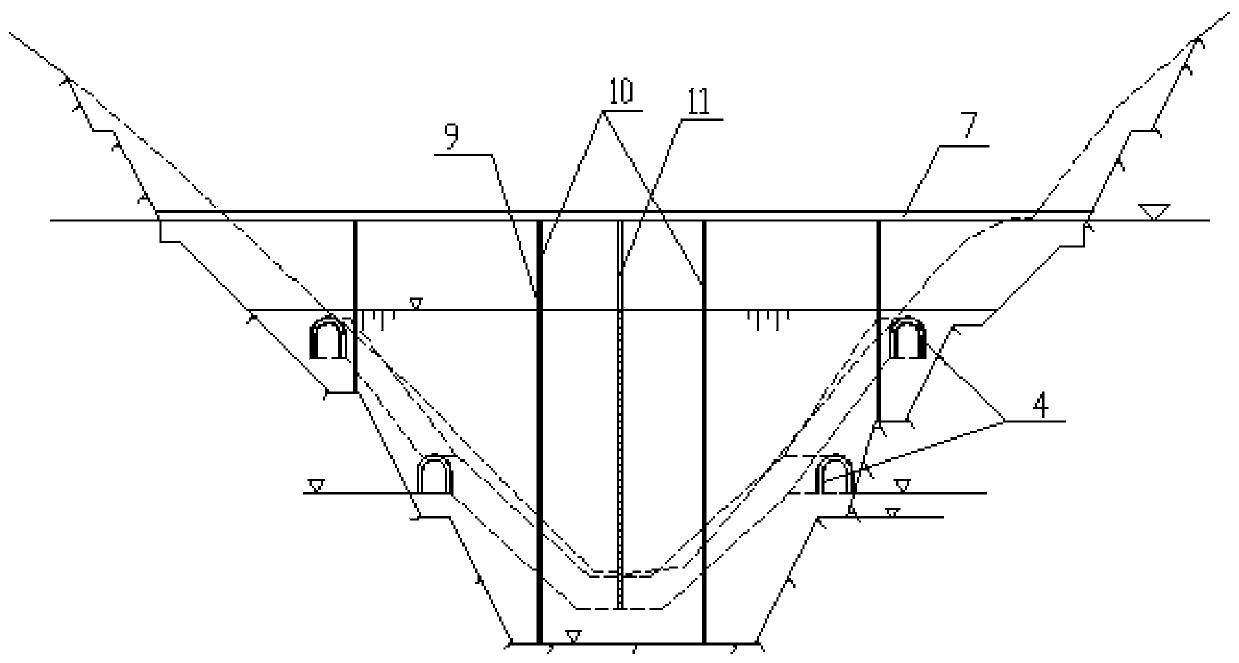

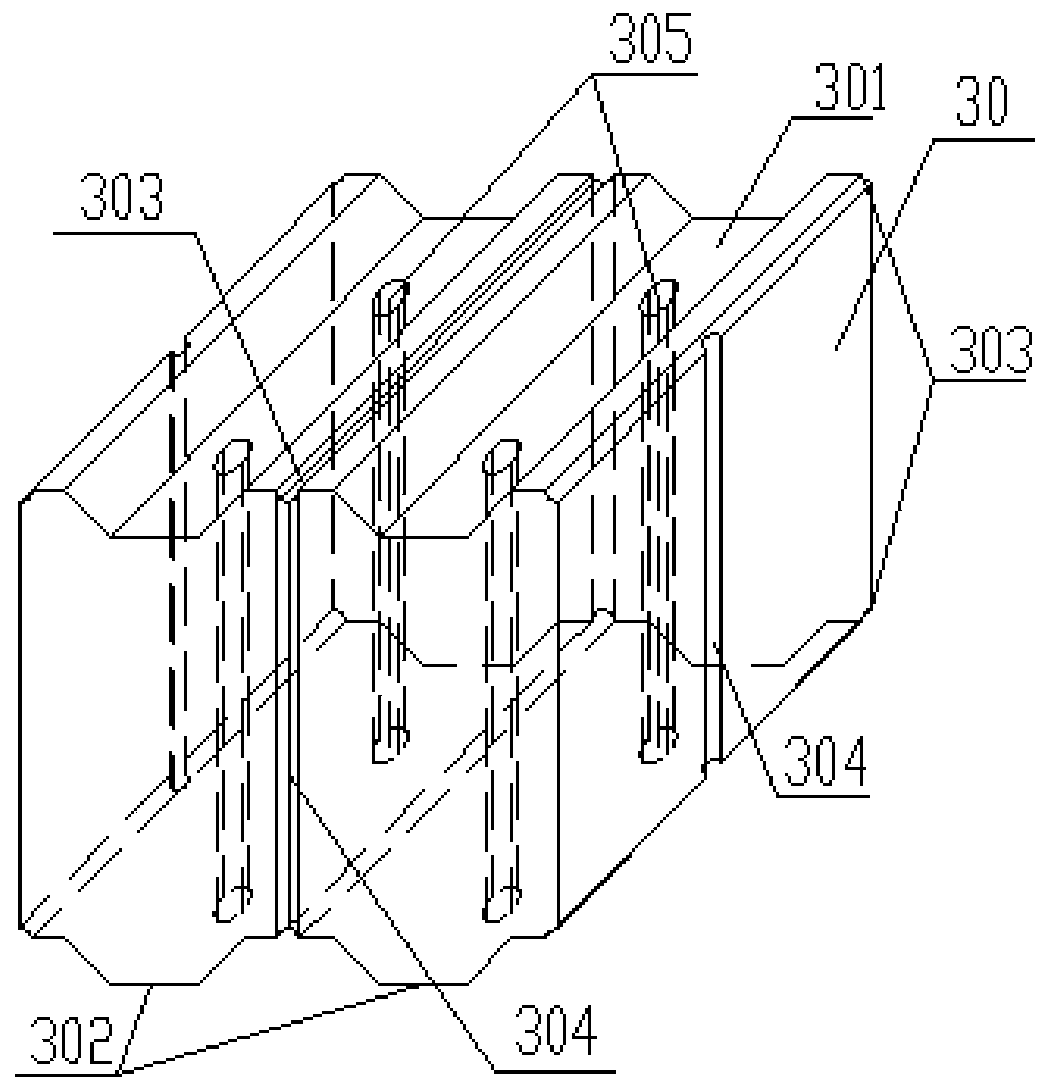

[0045] Embodiment 1: as Figure 1-6 As shown, a prefabricated tailings dam construction includes plain concrete cushion 1, permeable cushion 2, block 3, drainage corridor 4, dam foundation drainage hole 5, flood control wall 7, orifice drainage plate 8, horizontal Seam 9, plastic drainage board 10;

[0046] The plain concrete cushion 1 is directly poured on the foundation, the thickness may be 2-4m, and the permeable cushion 2 is laid on the plain concrete cushion 1, and the thickness may be 0.2m. The block dam is built on the permeable cushion 2 , the upstream side of the permeable cushion layer 2 is provided with a drainage gallery 4, and the bottom plate of the drainage gallery 4 is arranged with drainage holes 5 in the dam foundation, and the upstream side of the dam crest is provided with a flood control wall 7, and the block dam body is made of blocks 3 layer by layer, Two adjacent layers of blocks 3 are placed alternately, the block dam body is divided into several dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com