Equipment for cutting polyimide fiber and cutting method

A polyimide fiber and equipment technology, applied in the field of fiber production, can solve the problems of low cutting efficiency, long processing time, high cost, etc., achieve good cutting effect, reasonable design, and meet the application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

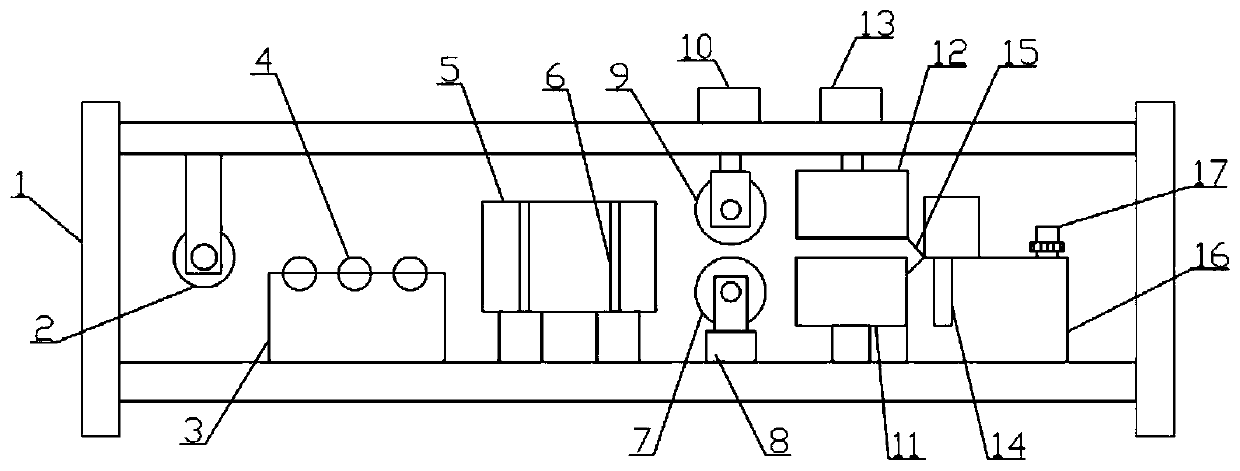

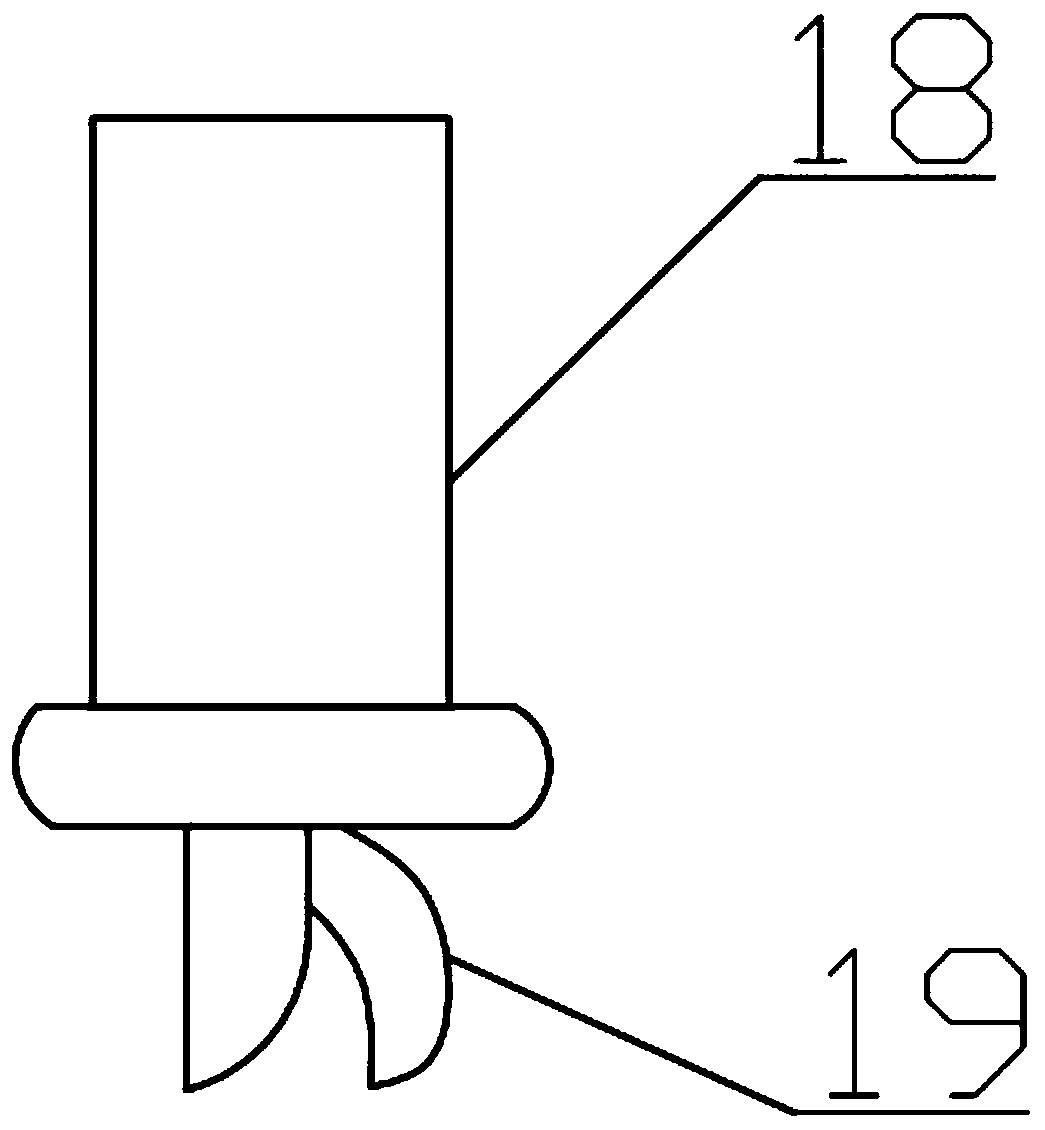

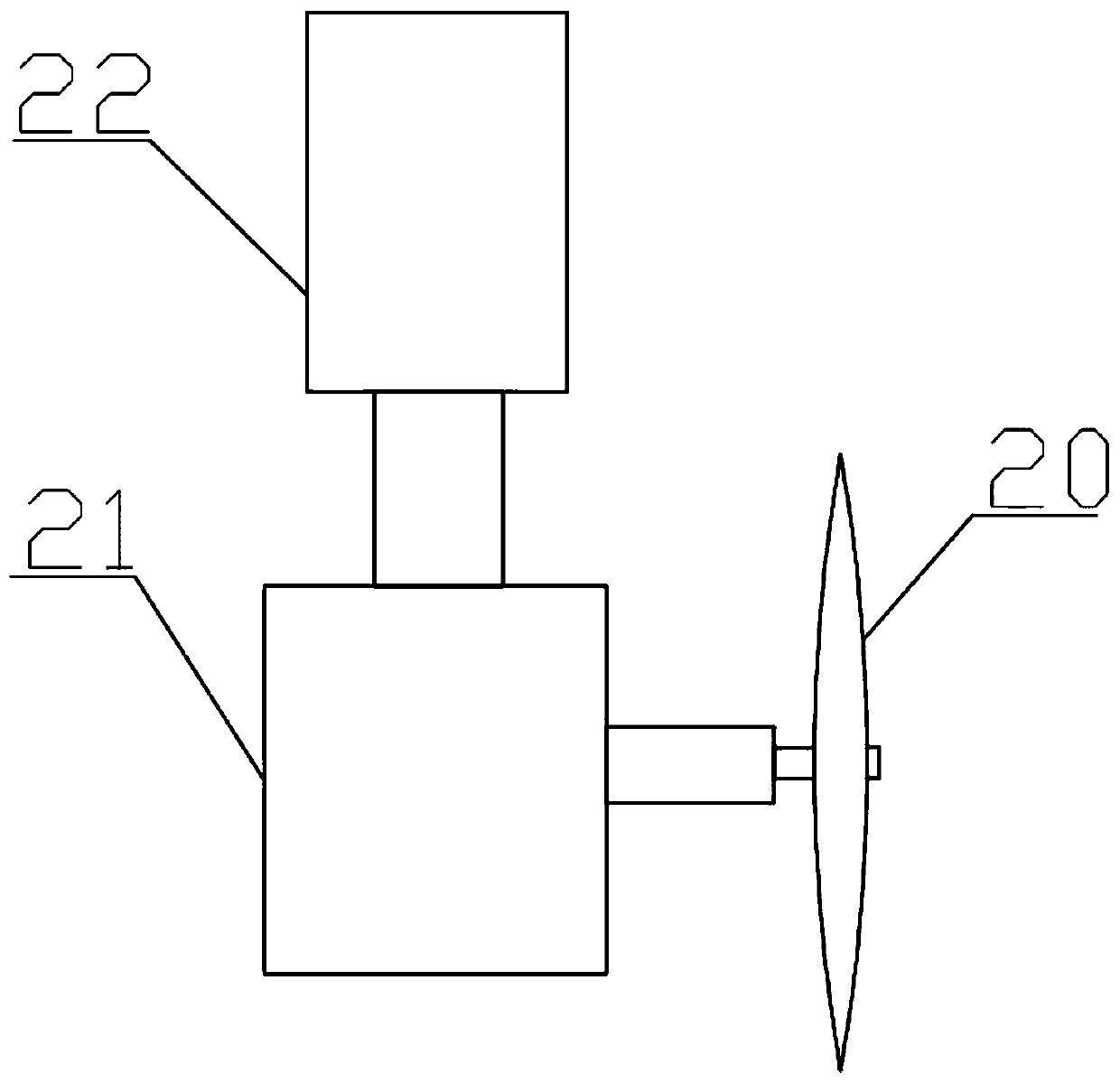

[0026] refer to Figure 1-5 , a kind of equipment that is used for polyimide fiber cutting, and this equipment comprises frame 1, and frame 1 is provided with and is used for processing polyimide fiber in sequence, tiling mechanism, sizing mechanism, sizing mechanism, feeding mechanism , clamping mechanism, shearing mechanism and wire storage mechanism;

[0027] The laying mechanism includes a laying roller 2 for evenly spreading several polyimide fibers, and the laying roller 2 is horizontally installed on the frame 1, and the laying roller 2 is spindle-shaped, which is convenient for polyimide After the fiber passes through the laying roller 2, it forms a flat state with uniform thickness distribution, which is convenient fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com