An economical low-temperature structural steel plate for polar regions and its manufacturing method

A structural steel plate and a manufacturing method technology, which are applied in the economical polar low-temperature structural steel plate and its manufacturing field, can solve the problems of increased control difficulty, increased production cost, fluctuation of steel plate performance, etc., so as to increase crack propagation resistance, ensure safe use, Low temperature toughness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

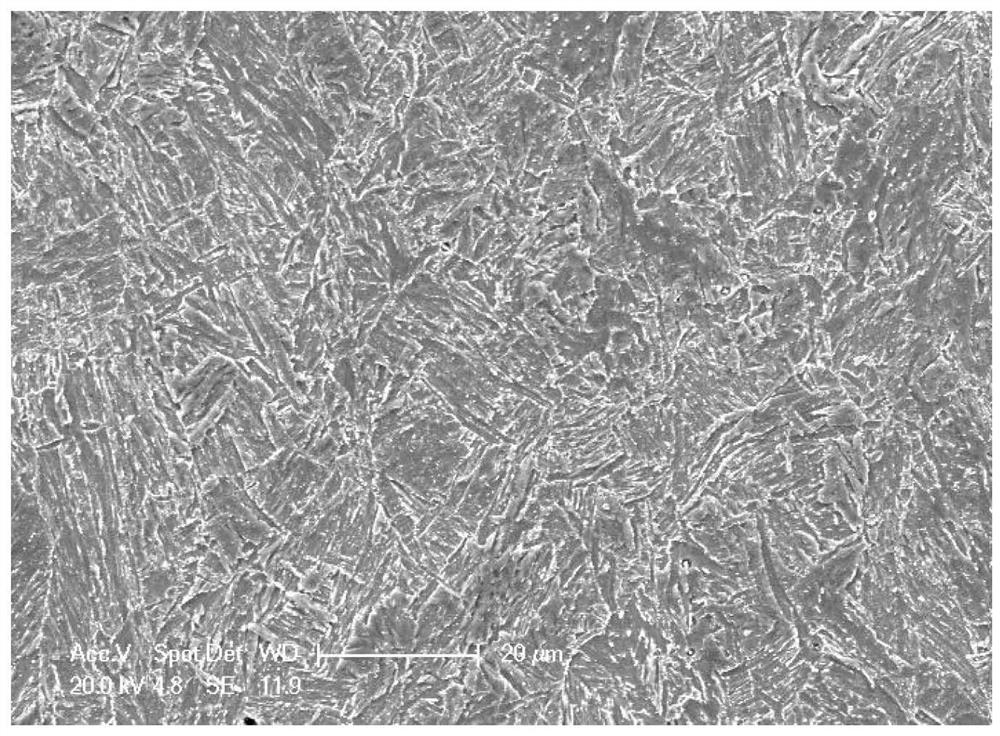

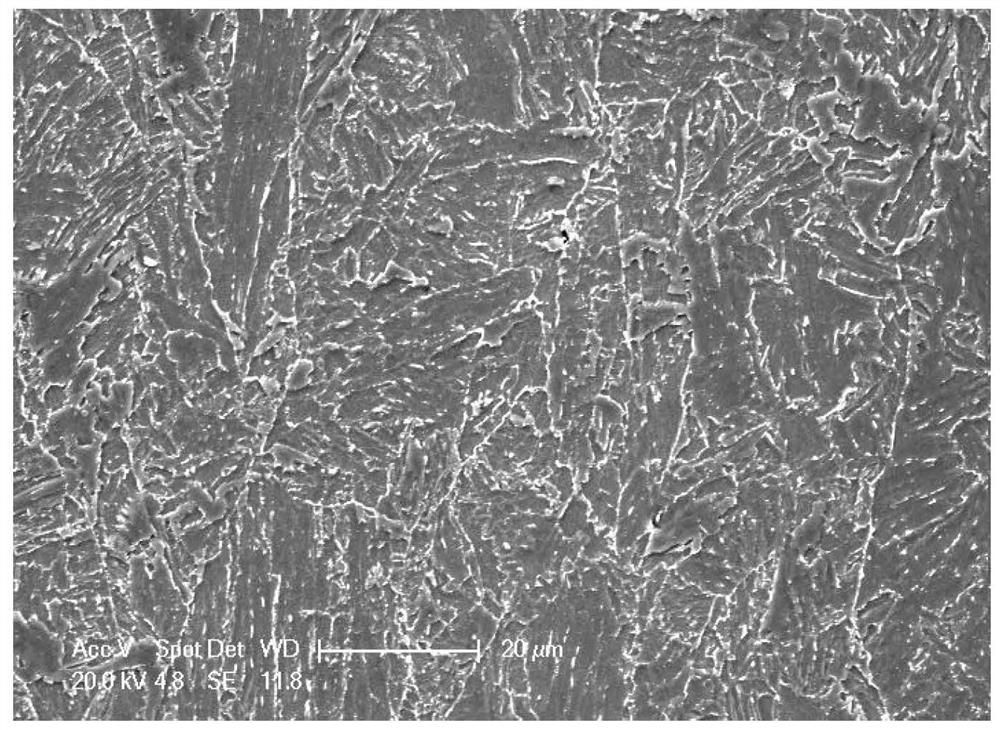

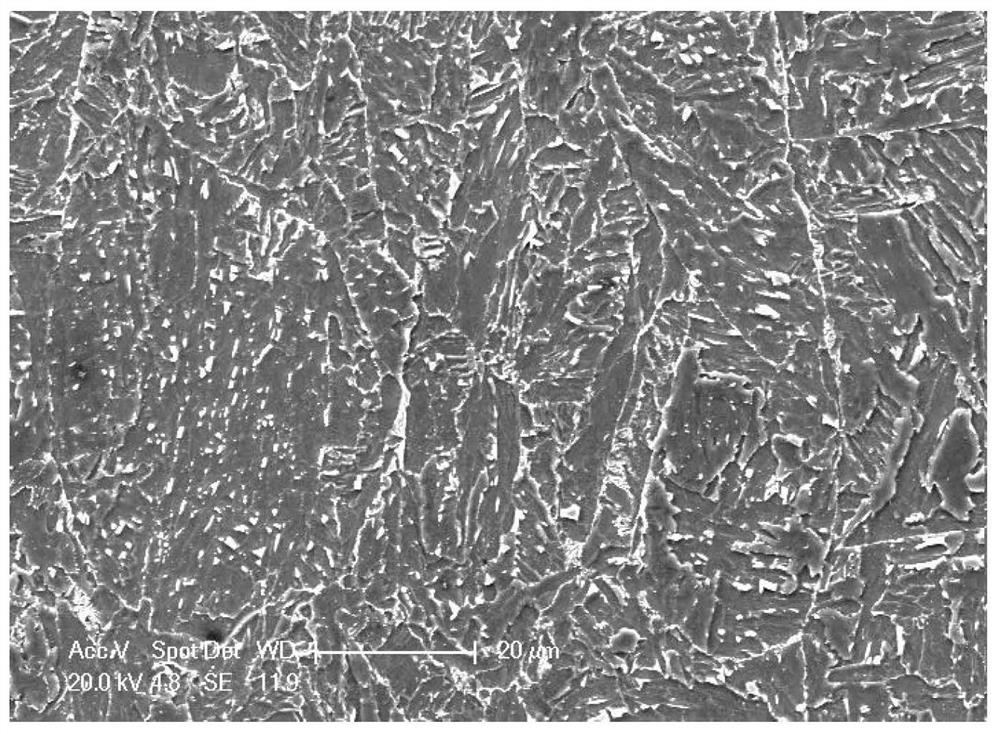

Image

Examples

Embodiment 1

[0023] According to chemical composition: C: 0.09%, Si: 0.34%, Mn: 1.37%, Nb: 0.045%, V: 0.038%, Ti0.018%, Als: 0.042%, Ni: 0.36%, P: 0.009%, S : 0.002%, CEV: 0.35%, the rest is Fe and unavoidable impurities smelted continuous casting slab. The cross-sectional size of the continuous casting slab obtained from the molten steel with qualified composition is 300×1820mm; after the hot continuous casting slab is cut into a fixed length, it is hoisted and stacked at a temperature of 750-700°C and slowly cooled for more than 3 days. The continuous casting slab is reheated, and the furnace time is controlled at 4.5 hours, and the furnace temperature is 1175°C. After coming out of the furnace, descale and enter the roughing mill for rolling. Rolling starts at 1056°C. The reduction ratios of the last two passes of this stage are controlled at 18.2 and 18.6% respectively, and the final final rolling temperature is guaranteed to be 1005°C. At this time, the rolling The thickness is 160mm...

Embodiment 2

[0025]According to chemical composition: C: 0.05%, Si: 0.17%, Mn: 1.28%, Nb: 0.026%, V: 0.024%, Ti0.022%, Als: 0.030%, Ni: 0.21%, P: 0.008%, S : 0.001%, CEV: 0.28%, the rest is Fe and unavoidable impurities smelted continuous casting slab. The cross-sectional size of the continuous casting slab obtained from molten steel with qualified composition is 250×2320mm; after the hot continuous casting slab is cut into a fixed length, it is hoisted and stacked at a temperature of 650-600°C and slowly cooled for more than 3 days. The continuous casting slab is reheated, and the furnace time is controlled for 4 hours, and the furnace temperature is 1145°C. After coming out of the furnace, descale and enter the roughing mill for rolling. The rolling starts at 1047°C. The reduction ratios of the last two passes of this stage are controlled at 16.7 and 17.1% respectively, and the final final rolling temperature is guaranteed to be 995°C. At this time, the rolled piece The thickness is 130...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com