Special slow-release fertilizer taking mineral soil as matrix and used for rice, and preparation method thereof

A technology of slow-release fertilizers and minerals, applied in fertilizer mixtures, solid/semi-solid fertilizers, phosphate fertilizers, etc., can solve the problems of inability to produce antibodies in plant roots and leaves, easy to be infested by insects, low fertilizer utilization rate, etc., and achieve improvement Rice quality, reduced fertilizer loss, and high fertilizer use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] The invention provides a technical solution: including bentonite, clay, talc, superphosphate, urea, potassium chloride, synthetic water-absorbing resin, microbial powder, aquatic shells, shrimp and crab shells, and nitrogen, phosphorus, and potassium, wherein it is formulated in parts by weight Ratio: 15 parts of bentonite, 8 parts of clay, 7 parts of talc, 6 parts of superphosphate, 3 parts of urea, 12 parts of potassium chloride, 24 parts of nitrogen, phosphorus and potassium, and 4 parts of microbial powder, Aquatic shells are 5 parts, shrimp and crab shells are 8 parts, and synthetic water-absorbing resin is 10 parts.

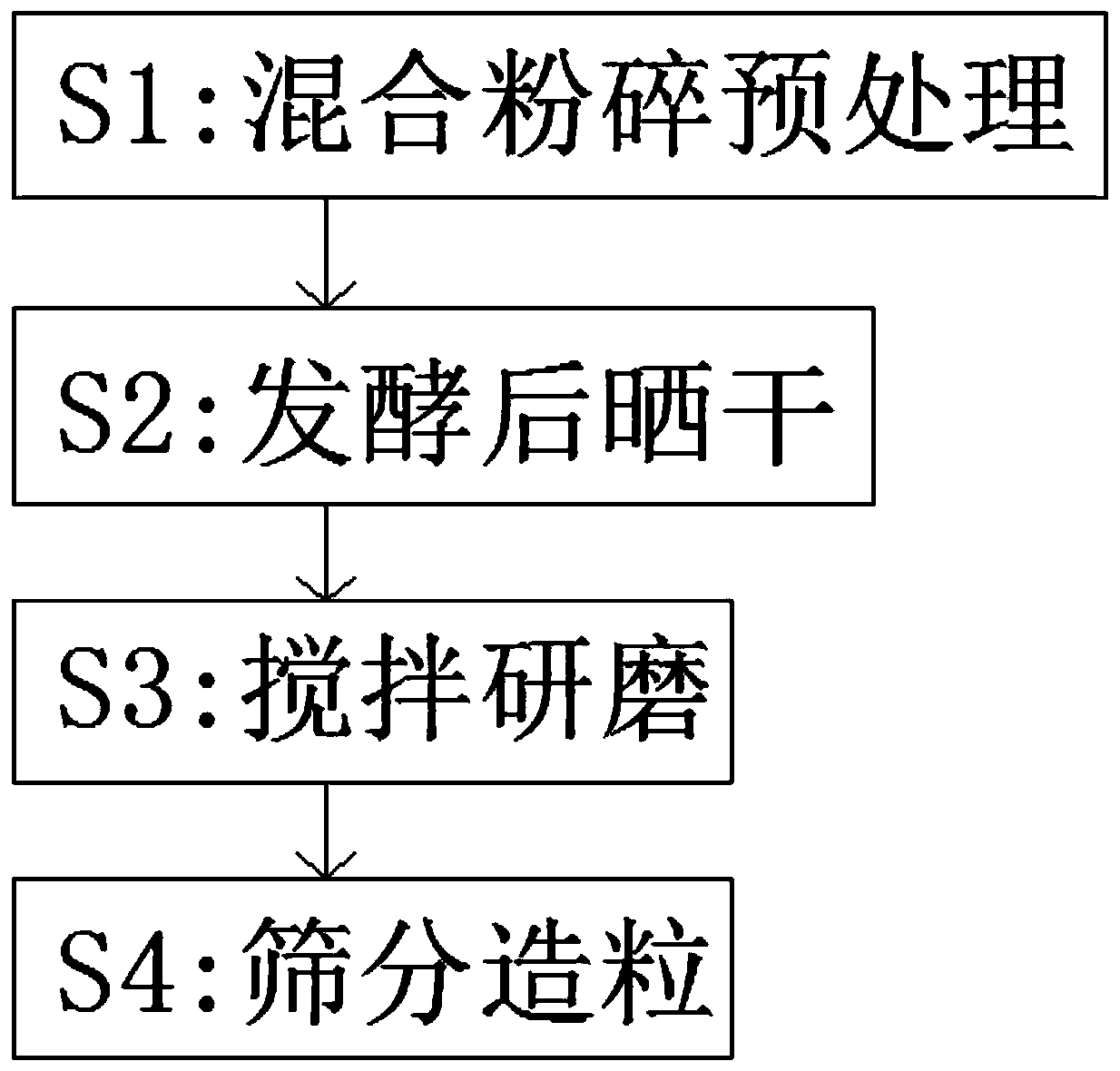

[0034] The production steps include the following:

[0035] S1, mixing and crushing pretreatment: first mix and feed bentonite, clay, talc and superphosphate, start the motor to drive the crushing roller to press and crush;

[0036] S2, drying after fermentation: mix microbial powder, aquatic shells and shrimp and crab shells, add water, add organic...

example 2

[0045] The invention provides a technical solution: including bentonite, clay, talc, superphosphate, urea, potassium chloride, synthetic water-absorbing resin, microbial powder, aquatic shells, shrimp and crab shells, and nitrogen, phosphorus, and potassium, wherein it is formulated in parts by weight Ratio: 10 parts of bentonite, 3 parts of clay, 5 parts of talc, 2 parts of superphosphate, 1 part of urea, 10 parts of potassium chloride, 15 parts of nitrogen, phosphorus and potassium, and 4 parts of microbial powder, Aquatic shells are 15 parts, shrimp and crab shells are 18 parts, and synthetic water-absorbing resins are 25 parts.

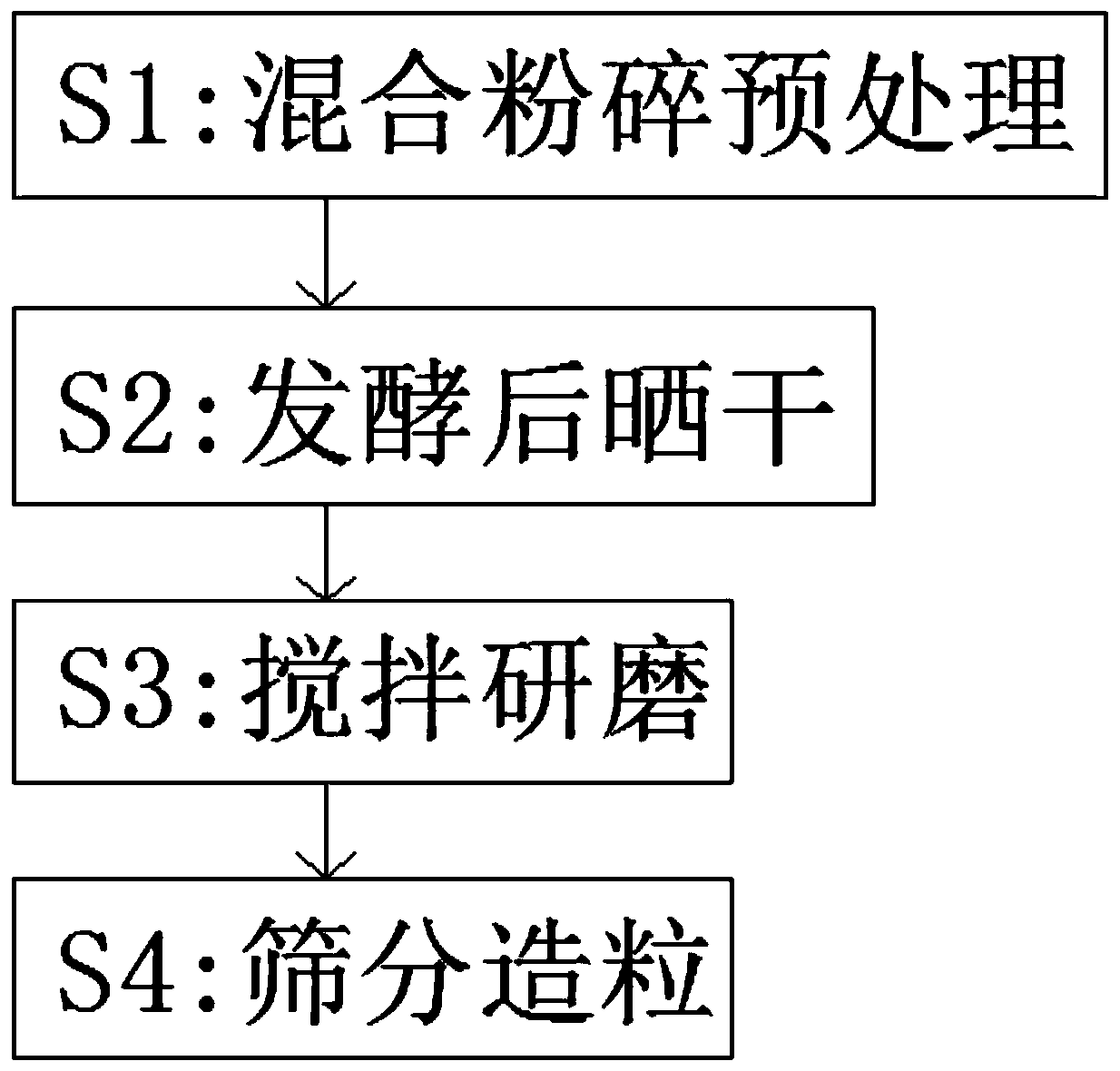

[0046] The production steps include the following:

[0047] S1, mixing and crushing pretreatment: first mix and feed bentonite, clay, talc and superphosphate, start the motor to drive the crushing roller to press and crush;

[0048] S2, drying after fermentation: mix microbial powder, aquatic shells and shrimp and crab shells, add water, add orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com