Method for preparing graphene heat dissipation film by using self-propagating stripping technology

A ene heat dissipation film and self-propagating technology, applied in the field of graphene, can solve the problems of low yield of large-scale graphene oxide, small size of graphene oxide sheet, low thermal conductivity of graphene film, etc., to achieve excellent heat dissipation effect, The effect of large size and high single-layer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

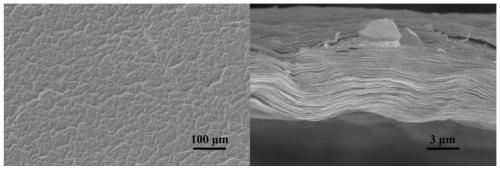

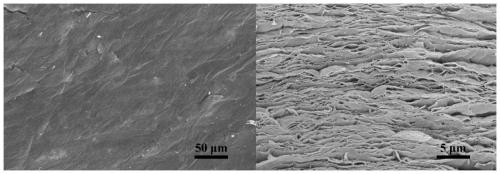

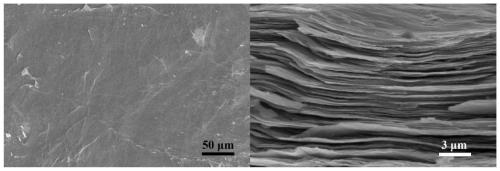

Image

Examples

Embodiment 1

[0036] 1) Graphite oxide with an average particle size of 1000 μm is prepared with water into a uniform dispersion with a mass fraction of 5%, and ammonia water is used to chemically modify the graphite oxide aqueous dispersion. The amount of modifier used is 0.1 times the mass of graphite oxide, and then vacuum Disperser, under the vacuum assistance of -0.1MPa, slowly stir and homogenize at a linear speed of 5m / s until the bubbles are completely removed, and obtain a modified graphite oxide slurry;

[0037]2) Use a scraper to evenly coat the modified graphite oxide slurry on a water-permeable nylon cloth to form a 4mm graphite oxide film, dry at 30°C to remove moisture, and peel off the substrate to obtain a modified graphite oxide film with a film thickness of 200 μm;

[0038] 3) After heating the modified graphite oxide film in step 2) on a rolling heating platform at 80°C, then lead it to a carbon fiber quartz electric heating tube heating platform for self-propagating peel...

Embodiment 2

[0047] 1) Graphite oxide with an average particle size of 400 μm is prepared with water into a uniform dispersion with a mass fraction of 1%, and ammonia water is used to chemically modify the graphite oxide aqueous dispersion. The amount of modifier used is 0.2 times the mass of graphite oxide, and then vacuum Disperser, under the vacuum assistance of -0.1MPa, slowly stir and homogenize at a linear speed of 1m / s until the bubbles are completely removed, and obtain a modified graphite oxide slurry;

[0048] 2) Use a scraper to evenly coat the modified graphite oxide slurry on a water-permeable nylon cloth to form a 1mm graphite oxide film, dry at 40°C to remove moisture, and peel off the substrate to obtain a modified graphite oxide film with a film thickness of 10 μm;

[0049] 3) After the modified graphite oxide film in step 2) is heated in a rolling heating platform at 50°C, it is then introduced to a carbon fiber quartz electric heating tube heating platform for self-propag...

Embodiment 3

[0053] 1) Graphite oxide with an average particle size of 100 μm is prepared with water into a uniform dispersion with a mass fraction of 3%, and ammonia water is used to chemically modify the graphite oxide aqueous dispersion. The amount of modifier used is 0.3 times the mass of graphite oxide, and then vacuum Disperser, under the vacuum assistance of -0.1MPa, slowly stir and homogenize at a linear speed of 3m / s until the air bubbles are completely removed to obtain a modified graphite oxide slurry;

[0054] 2) Use a scraper to evenly coat the modified graphite oxide slurry on a water-permeable nylon cloth to form a 5mm graphite oxide film, dry at 50°C to remove moisture, and peel off the substrate to obtain a modified graphite oxide film with a film thickness of 150 μm;

[0055] 3) Heat the modified graphite oxide film in step 2) on a rolling heating platform at 100°C, and then lead it to a metal tubular electric heating tube heating platform for self-propagating exfoliation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com