Preparation and applications of platinum-based framework iron molecular sieve alkane dehydrogenation catalyst

A technology of molecular sieve alkanes and dehydrogenation catalysts, which is applied in the direction of molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of poor selectivity of monoolefins, achieve excellent ability to adsorb alkanes, the method is simple, and the reaction rate is improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

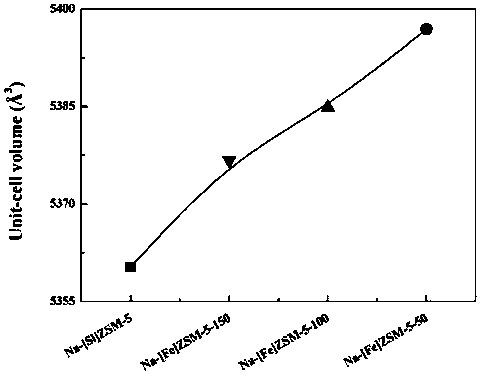

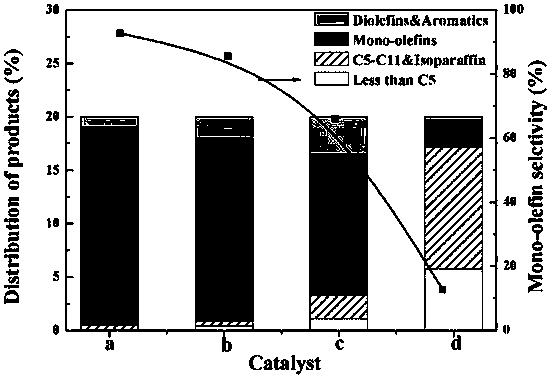

Embodiment 1

[0020] Measure 48 mL of tetraethyl orthosilicate and 16 mL of template tetrapropylammonium hydroxide to form a solution, then mix and stir at room temperature to obtain a mixed solution, weigh 0.8 g of ferric nitrate into it, and stir vigorously at room temperature until completely mixed. The obtained solution was placed in a 100mL hydrothermal reaction kettle and kept in an oven at 120°C for 1-2 hours, then raised to 170°C for crystallization for 48-60 hours. After crystallization, the sample was centrifuged and washed 3-4 times with deionized water, then dried overnight in an oven at 80°C, and calcined in a muffle furnace at 550°C (heating rate: 2°C / min) for 6 hours. After cooling a white solid powder was obtained.

[0021] Add a quantitative amount of platinum solution to the white solid powder by ion exchange method, dry the mixed sample in an oven overnight and then place it in a tube furnace and stir the mixed sample at 60°C for 12 hours in an air atmosphere , and then ...

Embodiment 2

[0023] Compared with the embodiment, the difference is that the volume of tetraethyl orthosilicate is 48mL, the volume of tetrapropyl ammonium hydroxide is 12mL, and the quality of ferric nitrate is 0.4g. Other operating conditions are the same as in Example 1, and the ferrosilicon molar ratio is 50:1 platinum-based skeleton iron molecular sieve alkane dehydrogenation catalyst (code b).

Embodiment 3

[0025] Compared with the embodiment, the difference is that the volume of tetraethyl orthosilicate is 48mL, the volume of tetrapropylammonium hydroxide is 10mL, and the quality of ferric nitrate is 0.6g. Other operating conditions are the same as in Example 1, and the ferrosilicon molar ratio is 150:1 platinum-based skeleton iron molecular sieve alkane dehydrogenation catalyst (code c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com