Medical vacuum system sterilization treatment device

A technology of sterilization treatment and vacuum system, which is applied in the direction of water supply equipment, waste disinfection or sterilization methods, sanitary equipment for toilets, etc., can solve the problems of large investment in equipment, large investment, complex system structure, etc., and achieve guaranteed The effect of meeting discharge standards, increasing contact time, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

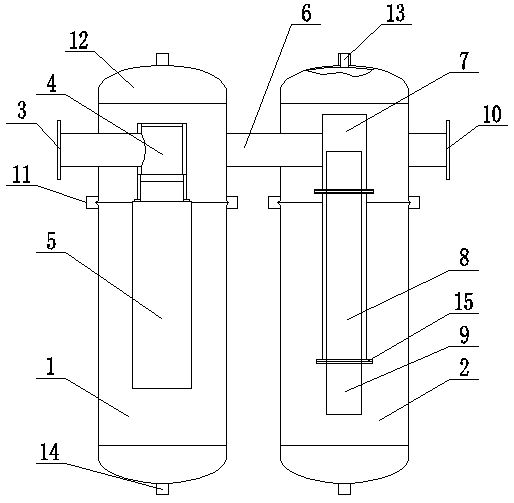

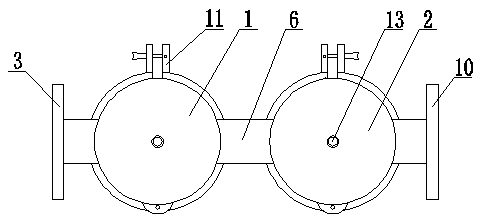

[0023] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

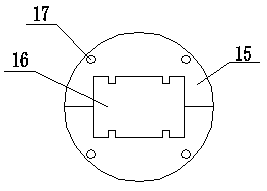

[0024] Such as figure 1 As shown, a medical vacuum system sterilization treatment device of this embodiment includes a first tank body 1 and a second tank body 2, both of which are cylindrical in structure, divided into It is an upper part and a lower part; the side of the first tank body 1 is provided with an air inlet 3, and the air inlet 3 is connected to the first sealing joint 4, and the lower end of the first sealing joint 4 is connected to the bacterial filter 5; The upper ends of the first tank body 1 and the second tank body 2 are provided with a connecting pipe 6, and the connecting pipe 6 is connected to a second sealing joint 7, and the second sealing joint 7 is connected to an intermediate pipe 8; the second tank body A sterilizer 9 is arranged inside the tank 2, and the sterilizer 9 is fixed on the second sealing joint 7 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com