MXene/silver nanowire composite electromagnetic shielding film

A silver nanowire and composite electromagnetic technology, which is applied in the fields of magnetic/electric field shielding, electrical components, metal processing equipment, etc., can solve the problem of low conductivity of electromagnetic shielding films, lack of multiple reflection effects, and impractical electromagnetic shielding effects Requirements and other issues, to achieve excellent electromagnetic shielding performance, improve the effect of multiple reflections, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

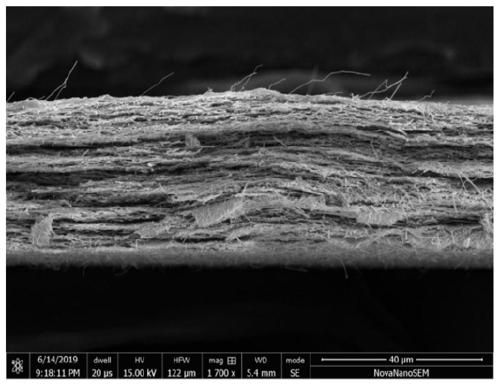

[0043] First, add the binder polyvinylpyrrolidone (Woke, K-30) to the silver nanowire aqueous solution with a concentration of 1.5 mg / mL (obtained by adjusting the concentration of the AgNW (PVP) dispersion prepared in the silver nanowire preparation example), The mass concentration of the binder is 0.1%, and the mixed solution 1 is obtained by magnetic stirring for 30 minutes. The MXene dispersion (obtained by diluting the MXene dispersion prepared in the MXene preparation example) with a concentration of 0.5 mg / mL was mixed with the mixed solution 1, so that the mass ratio of MXene to silver nanowires was 1, and magnetic stirring was used for 30 minutes. Mixture 2 was obtained. The mixed liquid 2 was subjected to negative pressure suction filtration using a polytetrafluoroethylene filter membrane with a pore size of 0.45 μm, and the thickness of the obtained composite electromagnetic shielding film was 40 μm.

Embodiment 2

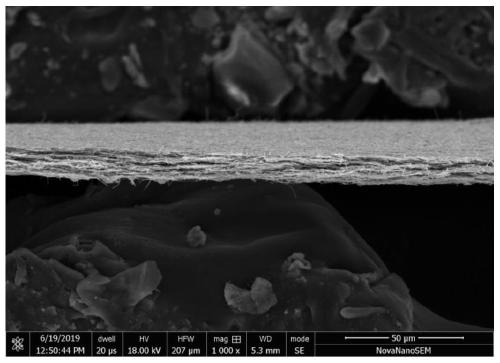

[0045] First, add the binder polyvinylpyrrolidone (Woke, K-30) to the silver nanowire aqueous solution with a concentration of 1 mg / mL (obtained by adjusting the concentration of the AgNW (PVP) dispersion prepared in the silver nanowire preparation example), wherein The mass concentration of the binder was 0.1%, and the mixed solution 1 was obtained by magnetic stirring for 30 minutes. The MXene dispersion (obtained by diluting the MXene dispersion prepared in the MXene preparation example) with a concentration of 1 mg / mL was mixed with the mixed solution 1, so that the mass ratio of MXene to silver nanowires was 3, and magnetic stirring was used for 30 minutes to obtain Mixture 2. The mixed liquid 2 was subjected to negative pressure suction filtration using a polytetrafluoroethylene filter membrane with a pore size of 0.45 μm, and the thickness of the obtained composite electromagnetic shielding film was 40 μm.

Embodiment 3

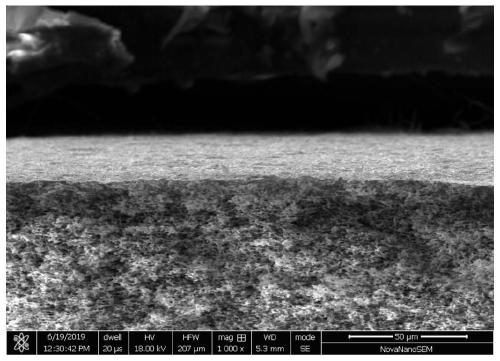

[0047] First, add the binder polyvinylpyrrolidone (Woke, K-30) to the silver nanowire aqueous solution with a concentration of 1.5 mg / mL (obtained by adjusting the concentration of the AgNW (PVP) dispersion prepared in the silver nanowire preparation example), The mass concentration of the binder is 0.1%, and the mixed solution 1 is obtained by magnetic stirring for 30 minutes. The MXene dispersion that concentration is 0.5mg / mL (obtained by diluting the MXene dispersion prepared by the MXene preparation example) is mixed with the mixed solution 1 according to the volume ratio of 1:1, so that the mass ratio of MXene to silver nanowires is 0.33, Magnetic stirring was used for 30 minutes to obtain a mixed solution 2. The mixed liquid 2 was subjected to negative pressure suction filtration using a polytetrafluoroethylene filter membrane with a pore size of 0.45 μm, and the thickness of the obtained composite electromagnetic shielding film was 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com