Spliced printed circuit substrate structure

A printed circuit substrate and splicing technology, which is applied to the structural connection of printed circuits, printed circuits, printed circuit components, etc. Stability of splicing, not easy to fall off and loose, and the effect of accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

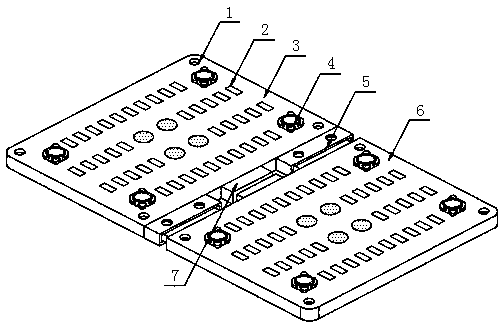

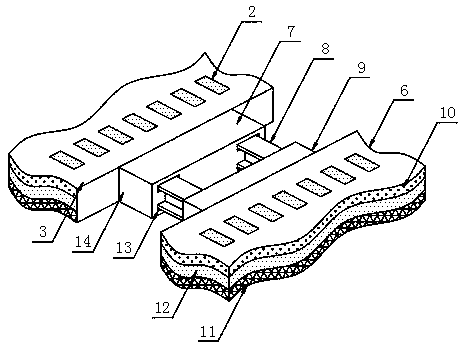

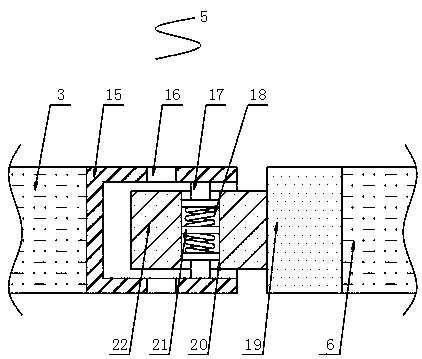

[0020] See Figure 1~4 In the embodiment of the present invention, a spliced printed circuit substrate structure includes a first substrate 3 and a second substrate 6 located on one side of the first substrate 3. The upper surface corners of the first substrate 3 and the second substrate 6 are both A first screw hole 1 is opened, and the inside of the first substrate 3 and the second substrate 6 are sequentially bonded with a base material layer 11, a circuit layer 12 and an insulating layer 10 from the inside to the outside, the first substrate 3 and the second substrate 6 LED chips 2 are embedded and mounted on the upper surfaces of the first substrate 3 and the second substrate 6 are embedded and mounted on the upper surface edges of the heat dissipation assembly 4, the heat dissipation assembly 4 includes a first heat sink 23, a first heat dissipation fin 24, heat The rod 25, the mounting rod 26, the second heat sink 27 and the second heat dissipation fin 28. The top end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com