Rotating disc type multi-station connection lead inserting device

A multi-station, turntable technology, used in fireworks, offensive equipment, weapon types, etc., can solve the problems of restricting the development of the fireworks industry, low degree of automation, low production efficiency, etc., to achieve high degree of automation, improve quality and work efficiency , the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

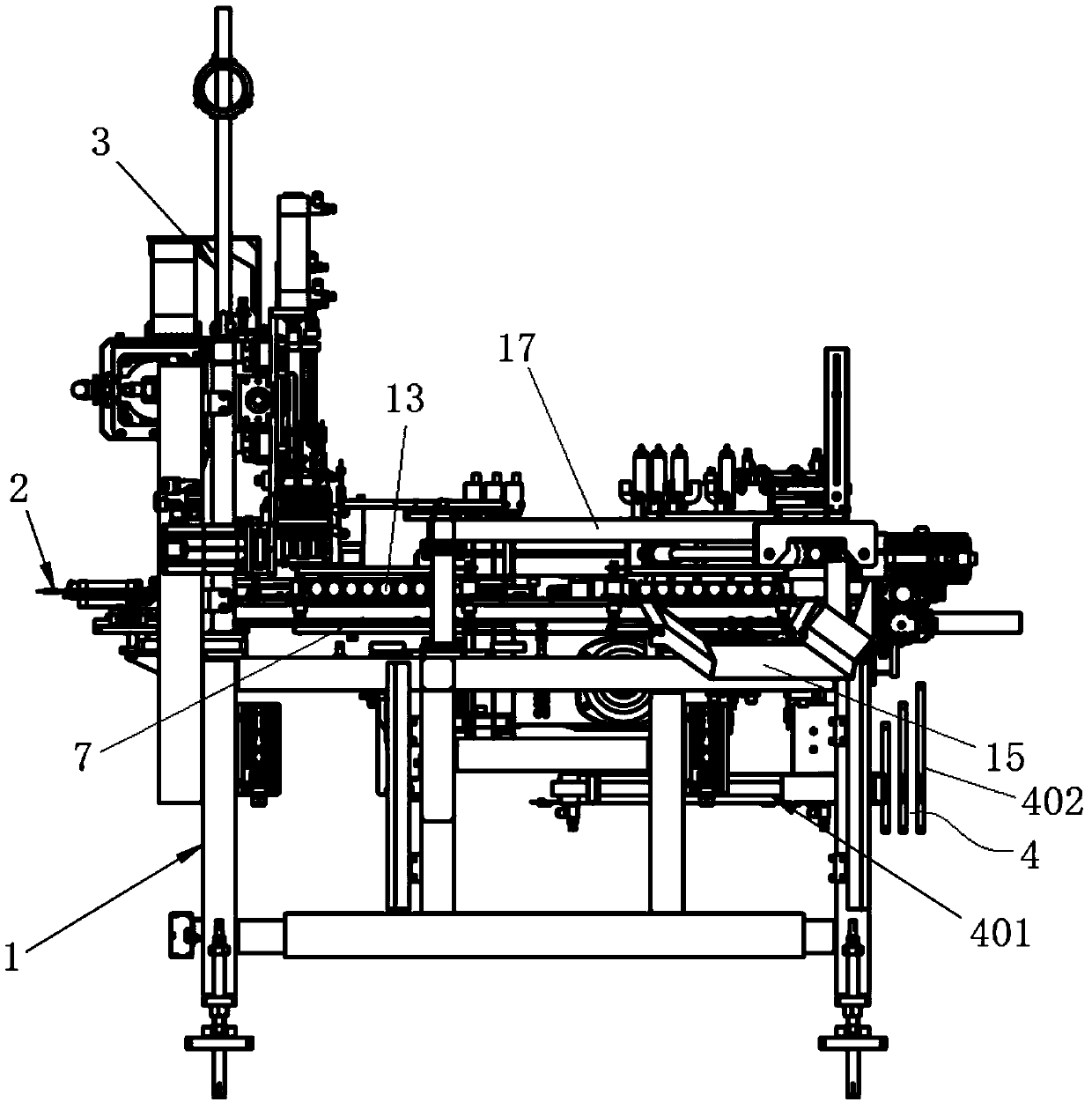

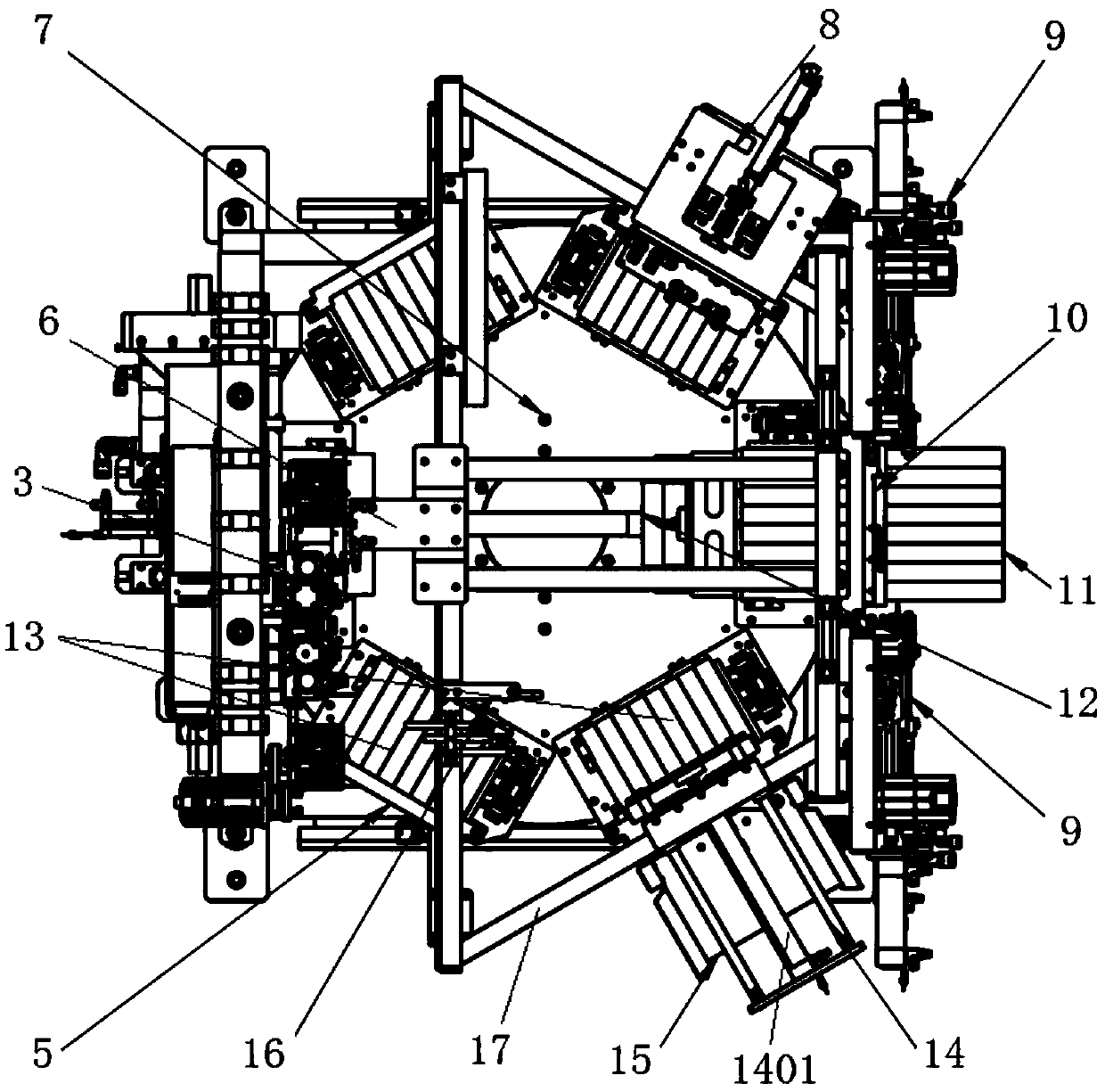

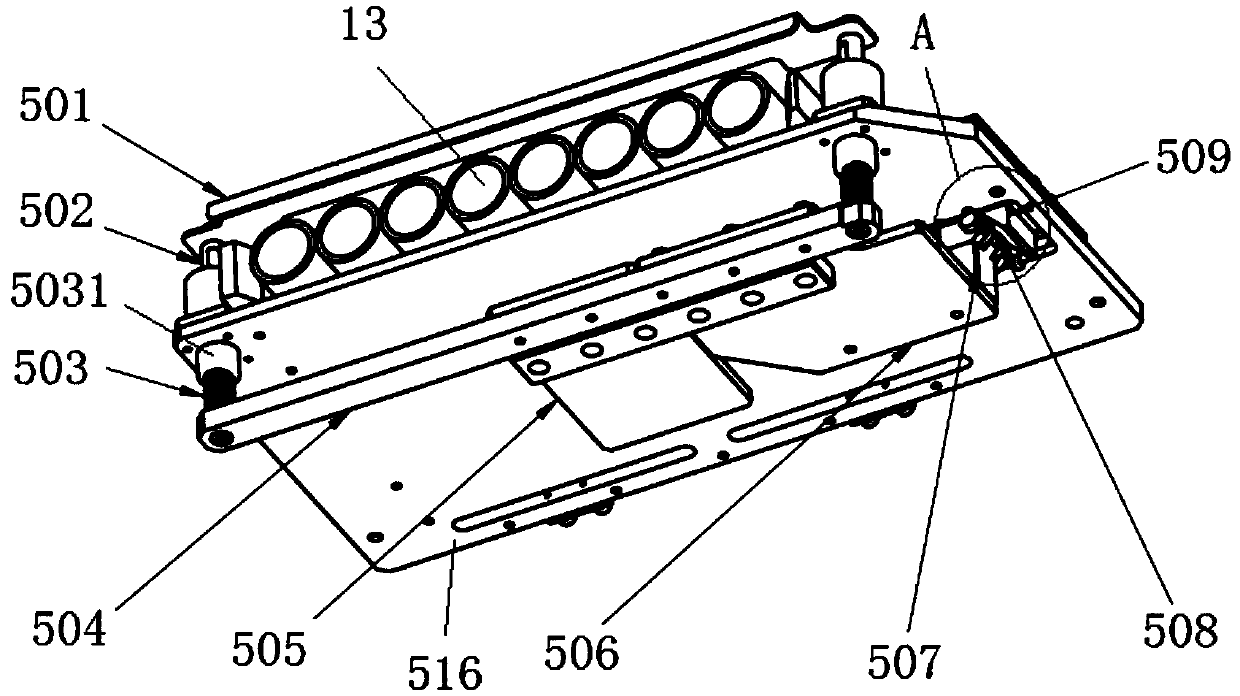

[0051] like Figure 1-30 As shown, the present invention includes a workbench support 1 and an indexing table 7, and the indexing table 7 is rotatably arranged on the workbench 1. In this embodiment, the indexing table 7 is driven by a motor Drive rotation, described indexing disc workbench 7 is known technology in the art, on described workbench support 1 along the circumferential direction of described indexing disc workbench 7, be provided with feeding station, detection station, The inserting station, the glue spraying station and the ejecting station are provided with a plurality of inserting and drawing outer cylinder clamping mechanisms 5 along the circumferential direction on the said indexing table 7. When the equipment is working, the outer cylinder 13 passes through the The insertion and introduction outer cylinder clamping mechanism 5 is clamped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com