A Downward Approach Filling Mining Method

A mining method and approach filling technology, which is applied in underground mining, filling, surface mining, etc., can solve the problems of reduced economic benefits of mine mining, difficulty in meeting market demand, and large amount of filling materials, so as to improve the comprehensive utilization rate , shorten recovery time and reduce the use of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

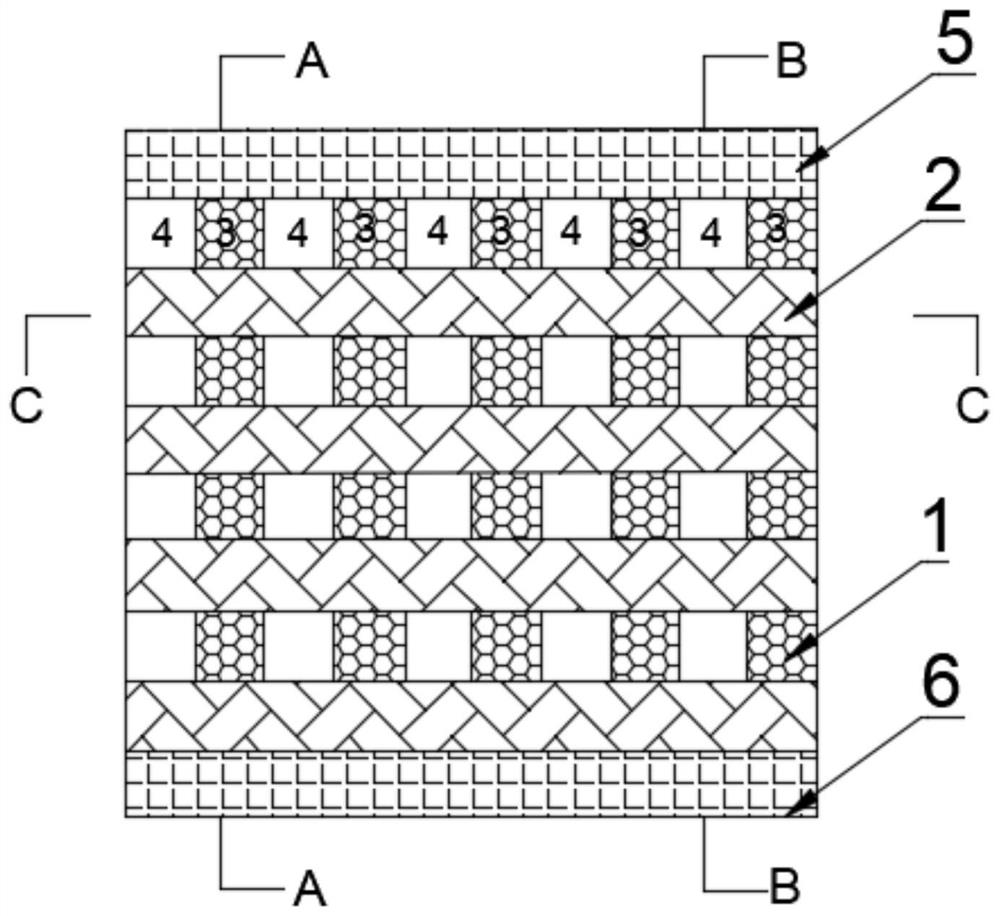

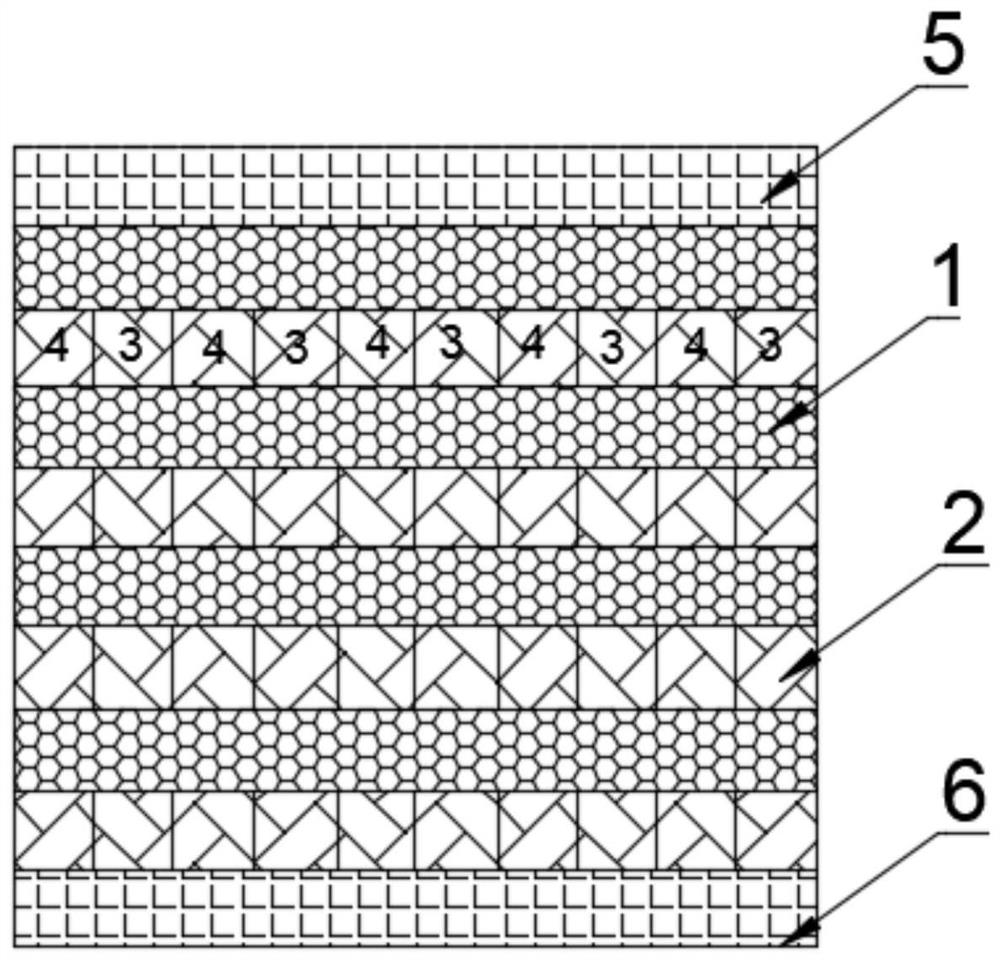

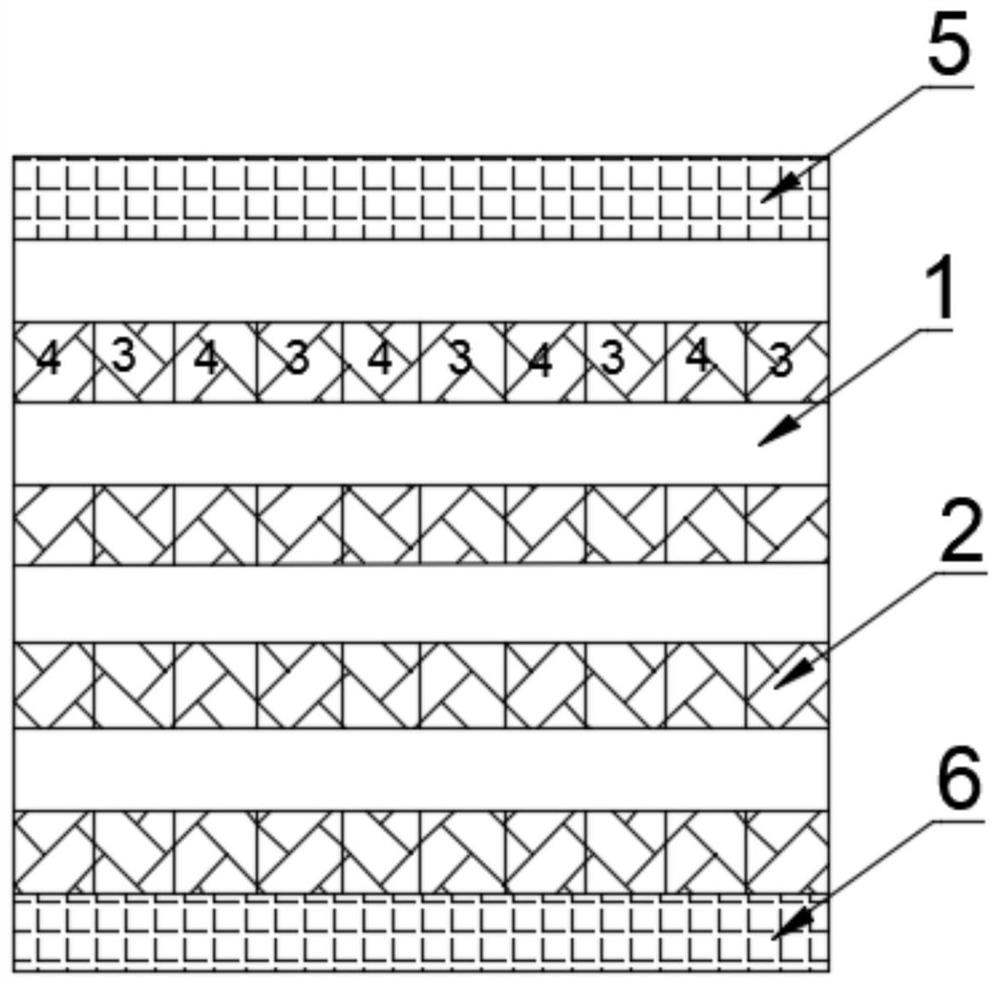

[0039] Such as Figure 1~4 As shown, a downward approach filling mining method includes the following steps:

[0040] S1. Ore block division: Divide the mining area into alternately distributed interval filling layers 1 and full filling layers 2 from the vertical direction. The access routes are arranged orthogonally and alternately distributed at equal heights, forming the stope roof 5, the stope floor 6 and the stope surrounding rock 7;

[0041] S2. Divide the gap filling layer 1 and the full filling layer 2 into a plurality of alternately distributed first bars 3 and second bars 4, the gap filling layer 1 and the full filling layer 2 The first bar 3 and the second bar 4 are equal sections with equal width and height;

[0042] S3. The mining sequence in the stope area is mining layer by layer in the downward approach, in which the adjacent interval filling layer 1 and the complete filling layer 2 are arranged perpendicular to each other;

[0043] S4. When exploiting the i...

Embodiment 2-5

[0053] Embodiments 2-5 provide a mining method for filling downwards. Compared with Embodiment 1, the difference is that in step S4, the mass percentage of the raw material composition of the high-strength quick-setting filling material is changed, except for the above differences , and other operations are the same, and will not be repeated here; the specific condition parameters and the results of setting time and compressive strength of each filling body are shown in the table below.

[0054]

[0055] It can be seen from the results in the above table that changing the mass percentage of the raw material composition of the high-strength quick-setting filling material described in step S4 will have a significant impact on the coagulation time and compressive strength of the coagulated filling body, and the raw material ratio of Example 1 is lower. The comprehensive properties of setting time and compressive strength of the formed filling body are the best. Comparing the r...

Embodiment 6-12

[0057] Embodiments 6-12 provide a mining method for filling downwards. Compared with Embodiment 1, the difference is that in step S4, the particle size range and the size range of the waste rock in the high-strength quick-setting filling material are changed. Weight ratio, except for the above differences, other operations are the same and will not be repeated here; the specific condition parameters and compressive strength results of each filling body are shown in the table below.

[0058]

[0059] As can be seen from the results in the above table, changing the particle size range and weight ratio of the waste rock in the high-strength quick-setting filling material described in step S4 will have a significant impact on the compressive strength of the filling body after setting, and Example 1 Under the ratio of raw materials, the comprehensive performance of compressive strength of the formed filling body is the best. Comparing the results of Example 1, Examples 6-7 and E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com