Super-hydrophilic underground oil-water separator and sucker-rod pump same-well injection-production process pipe string thereof

An oil-water separator and separator technology, applied in wellbore/well components, drill pipes, drill pipes, etc., can solve the problems of only 50% success rate, small processing capacity, affecting service life, etc., and achieve the processing capacity. Adjustable, high separation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

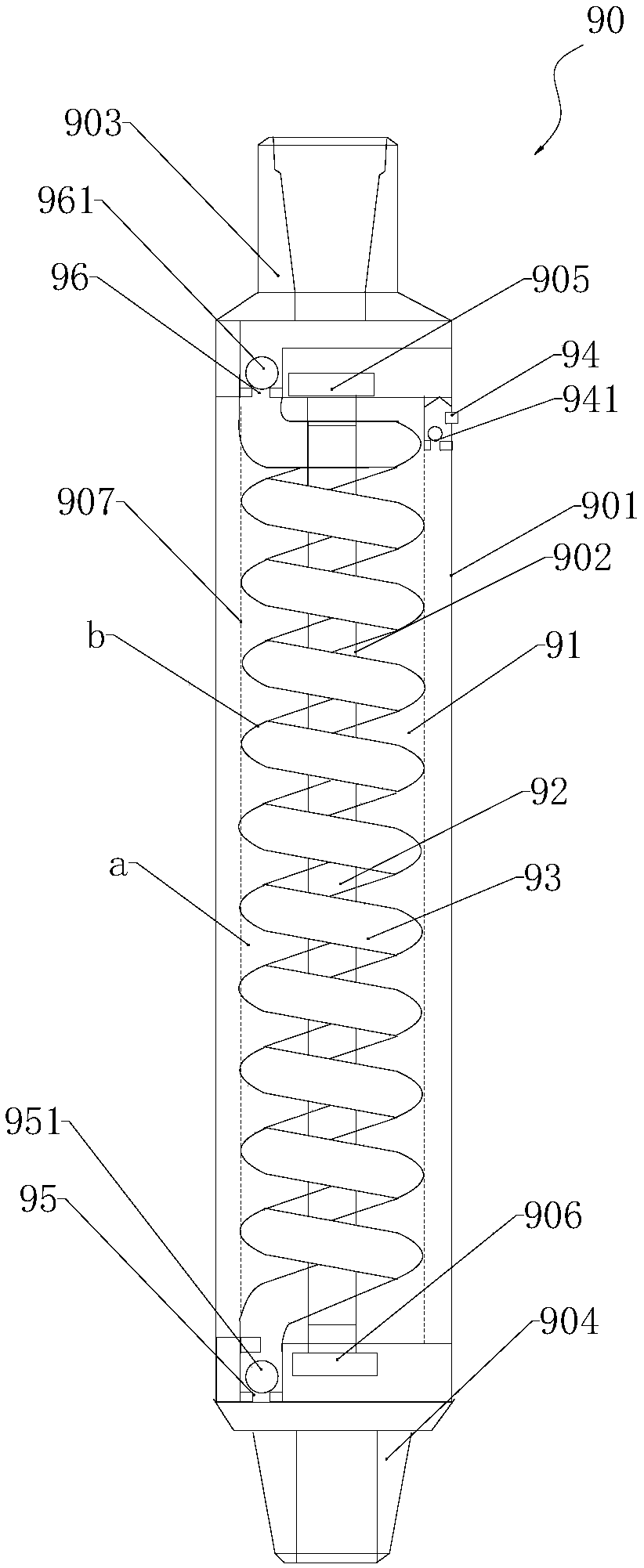

[0028] Such as figure 1 As shown, the present invention provides a super-hydrophilic downhole oil-water separator 90. The inside of the oil-water separator 90 is provided with three passages, which are respectively the outer annular passage 91 of the separator, the inner annular passage 92 of the separator and the main passage of the separator. Channel 93. Among them, the inner annular channel 92 of the separator is used for sealing the sucker rod to pass through, the outer annular channel 91 of the separator is used to store the separated water and form a water flow channel, and the main channel 93 of the separator is the liquid of crude oil with high water content. The crude oil with high water content is dehydrated while flowing through the main channel 93 of the separator, and the separated water enters the outer annular channel 91 of the separator, and the dehydrated crude oil continues upward through the main channel 93 of the separator. Therefore, the separator inner a...

Embodiment 2

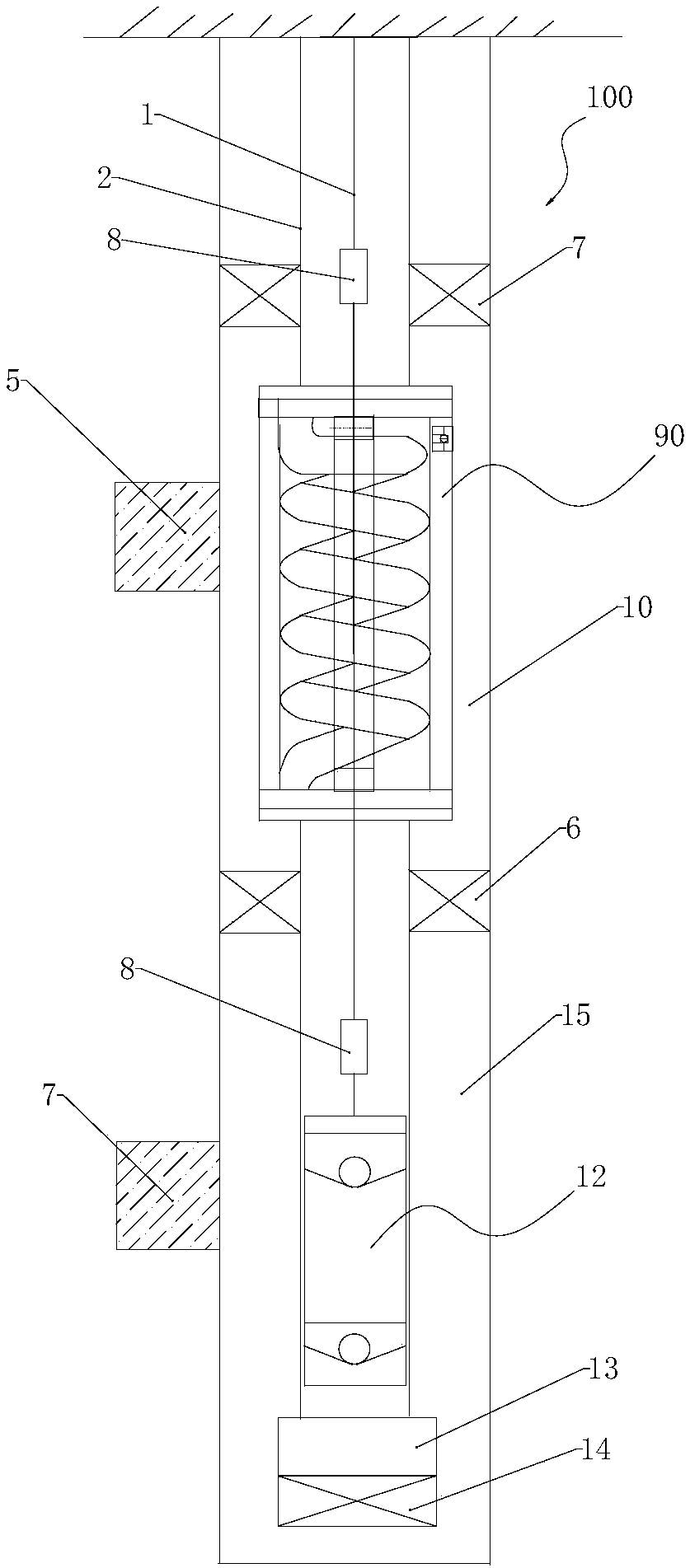

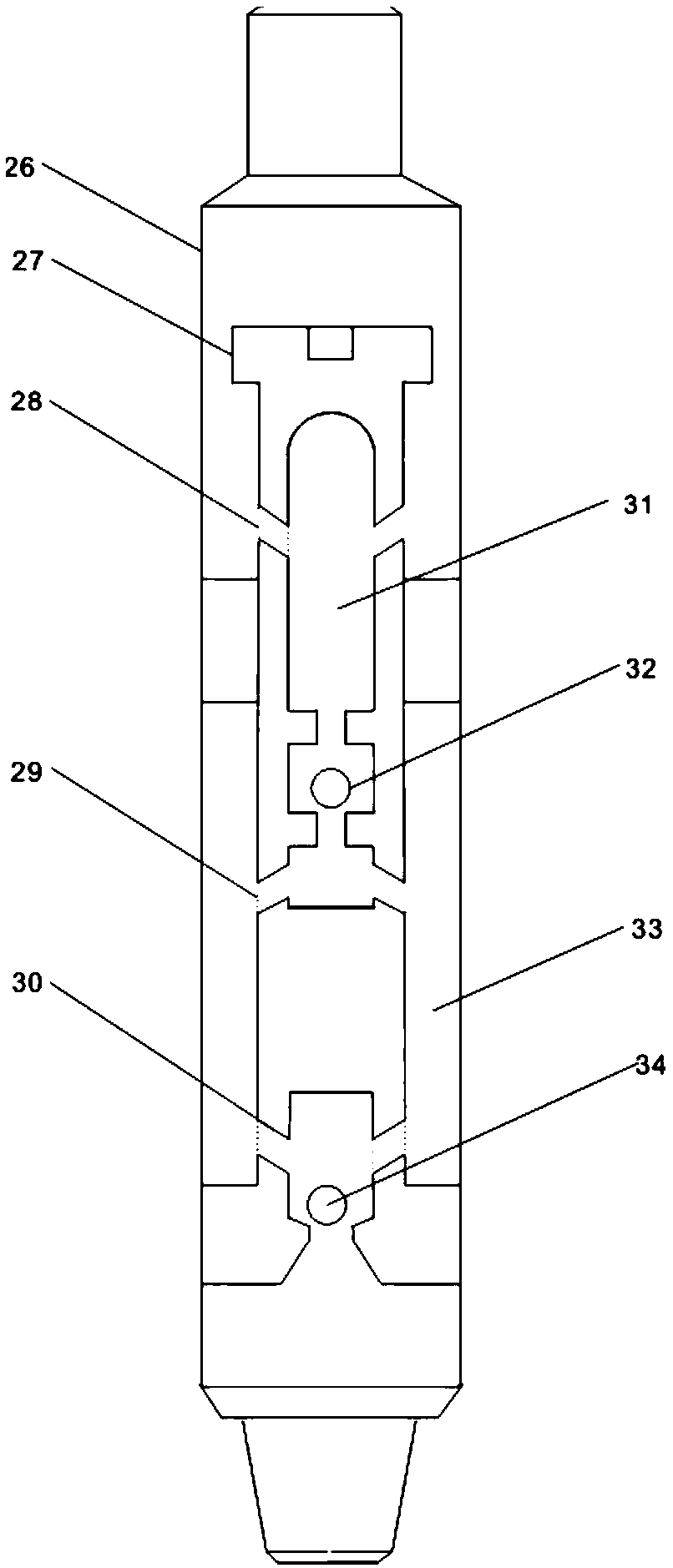

[0037] Such as figure 2 As shown, the present invention also provides a rod pump injection-production process string 100 in the same well. The process string 100 is set in the casing, including the rod pump 12, the packer and the oil-water separation in the first embodiment. device 90. Rod oil well pump 12 can adopt the rod oil well pump of the prior art, as image 3 As shown, the present embodiment adopts the conventional rod well pump 12 commonly used in oil fields and mines at present. The rod well pump 12 includes a pump barrel 26, a plunger 27, a liquid outlet hole 28 in the upper part of the plunger, a liquid inlet hole 29 in the middle part of the plunger, a liquid outlet hole 30 in the lower part of the plunger, a liquid inlet channel 31, an upstream valve 32, and an annular cavity 33. Downstream Verse 34. The oil-water separator 90 is set above the rod well pump 12, and the number of packers is set according to the needs. In this embodiment, a lower packer 6 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com