Oblique prestress bridge deck pavement structure and construction method thereof

A bridge deck pavement and construction method technology, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of easy cracking of reinforced concrete pavement layer and unreliable performance of reinforced concrete bridge deck structure, and achieve the improvement of stress shape , increase the strength, increase the effect of force range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

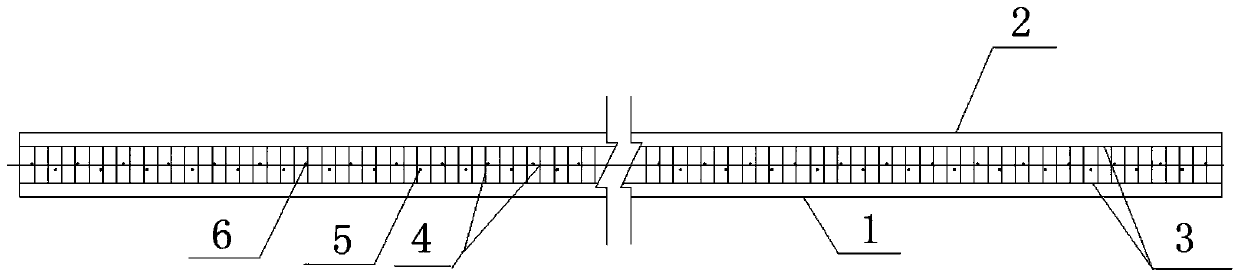

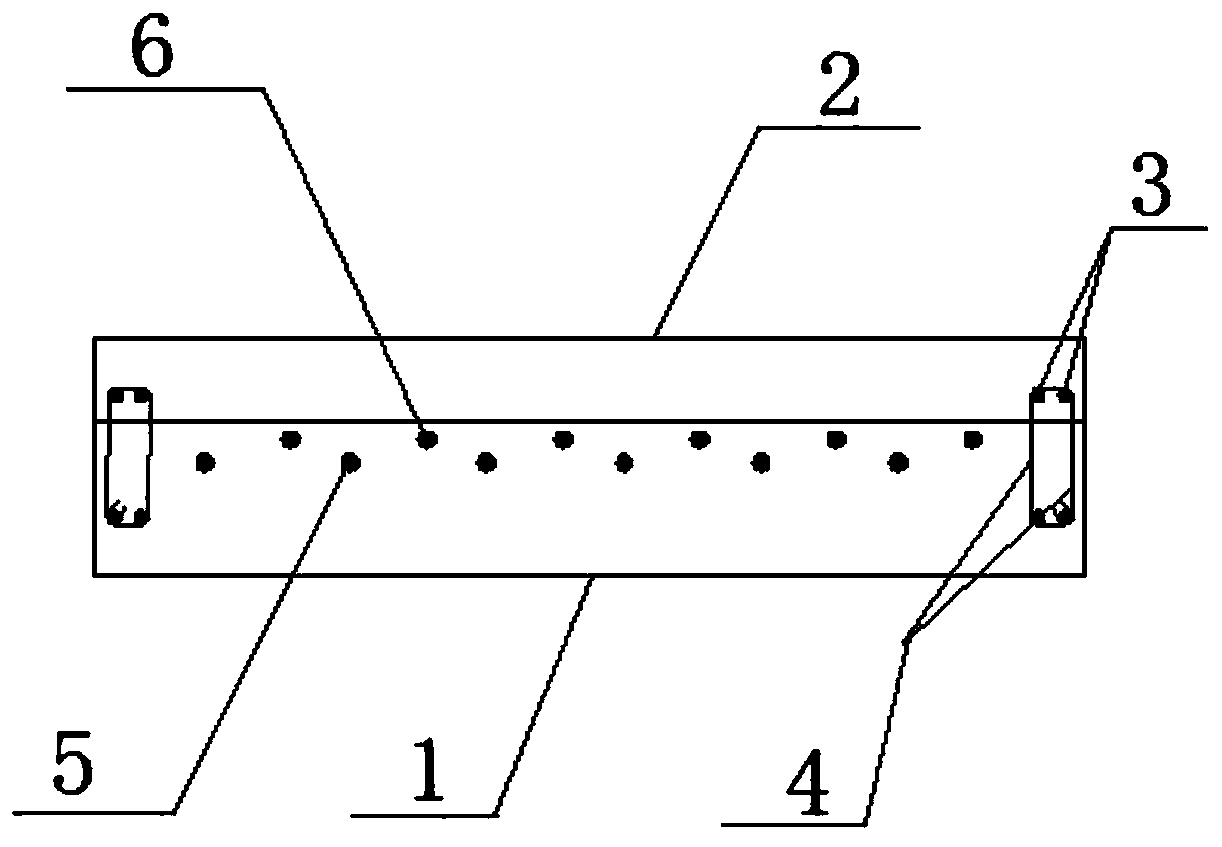

[0070] Please refer to figure 1 As shown, a kind of oblique prestressed bridge deck pavement structure of the present embodiment comprises: concrete; The prestressed tendon pavement layer, the prestressed tendon adopts a steel strand with a diameter of 15.2mm; the structural steel bar 3, along the height direction, the structural steel bar 3 is horizontally arranged in the oblique prestressed tendon pavement layer, and the The structural reinforcement 3 is parallel to the long side of the oblique prestressed tendon pavement layer; the stirrup 4 is used to fix the structural reinforcement 3 and is perpendicular to the structural reinforcement 3.

[0071] Compared with the existing technology, the oblique prestressed bridge deck pavement structure of this scheme includes concrete, prestressed tendons, structural steel bars 3 and stirrups 4, and the oblique prestressed bridge structure is formed by prestressed tendons, structural steel bars 3 and stirrups 4. The basic skeleton s...

Embodiment 2

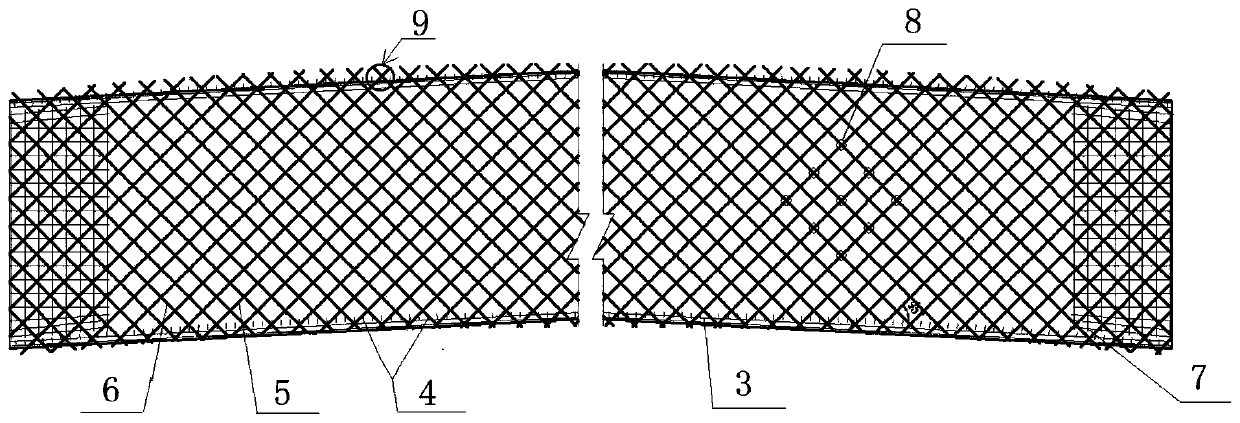

[0076] An oblique prestressed bridge deck pavement structure of this embodiment, compared with Embodiment 1, further, a beam plate is arranged under the oblique prestressed tendon pavement layer, and the beam plate is passed through a steel bar. The frame 8 is fixed with the oblique prestressed tendon pavement layer as a whole, which increases the strength of the bridge and effectively prolongs the service life of the bridge deck pavement structure; the steel frame 8 is an inverted U-shaped structure, and the inverted The U-shaped structure is arranged at the intersection of the upper layer prestressed tendons 6 and the lower layer prestressed tendons 5 at intervals, the upper part of the inverted U-shaped structure is respectively fixed with the upper layer prestressed tendons 6 and the lower layer prestressed tendons 5, and the lower part is fixed with the beam plate Fix it to ensure that the upper prestressed tendon 6 is 5.5cm away from the oblique prestressed tendon pavemen...

Embodiment 3

[0082] A kind of oblique prestressed bridge deck pavement structure of the present embodiment, compared with embodiment 2, further, combines Figure 4, also includes plate end reinforcing bars 7, the plate end reinforcing bars 7 are arranged at both ends of the bridge, and are arranged below the prestressed tendons, and the plate end reinforcing bars 7 are 30×30cm Single-layer steel mesh, and the diameter of the steel bar is 8mm.

[0083] Add plate end reinforcing steel bars 7 at both ends of the bridge, and set the plate end reinforcing steel bars 7 below the lower prestressed tendons 5. Due to the relatively large stress on the two ends of the bridge, additional The reinforcing bar 7 at the end of the slab consolidates the two ends of the bridge to prevent cracking at the two ends of the concrete. In addition, the slab end reinforcing steel bar 7 is designed as a 30×30cm single-layer steel mesh, and the diameter of each steel bar is 8mm. Dispersion increases the strength o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com