A kind of mattress fabric dyeing agent and dyeing method

A dyeing method and dyeing agent technology, which are applied in the field of dyes and dyeing and finishing, can solve the problems of difficult dyeing liquid handling, difficulty in free movement, and large pollution, and achieve improved color fastness and dyeing rate. The preparation method is simple and feasible, and the wall The effect of high material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a dyeing agent for mattress fabric, which is a disperse dye microcapsule, which is composed of disperse dye, wall material and dispersant. The wall material is carboxyl-terminated low-melting polyester, the core material is disperse dye, and the dispersant is Sodium methylene bis-naphthalene sulfonate, the mass ratio of disperse dye, wall material and dispersant is 1:3.5:1. Among them, the carboxyl-terminated low-melting polyester is composed of phthalic anhydride, terephthalic acid segment, isophthalic acid segment, ethylene glycol segment, diethylene glycol segment and benzoic acid end capping agent, and the melting point is about 110°C.

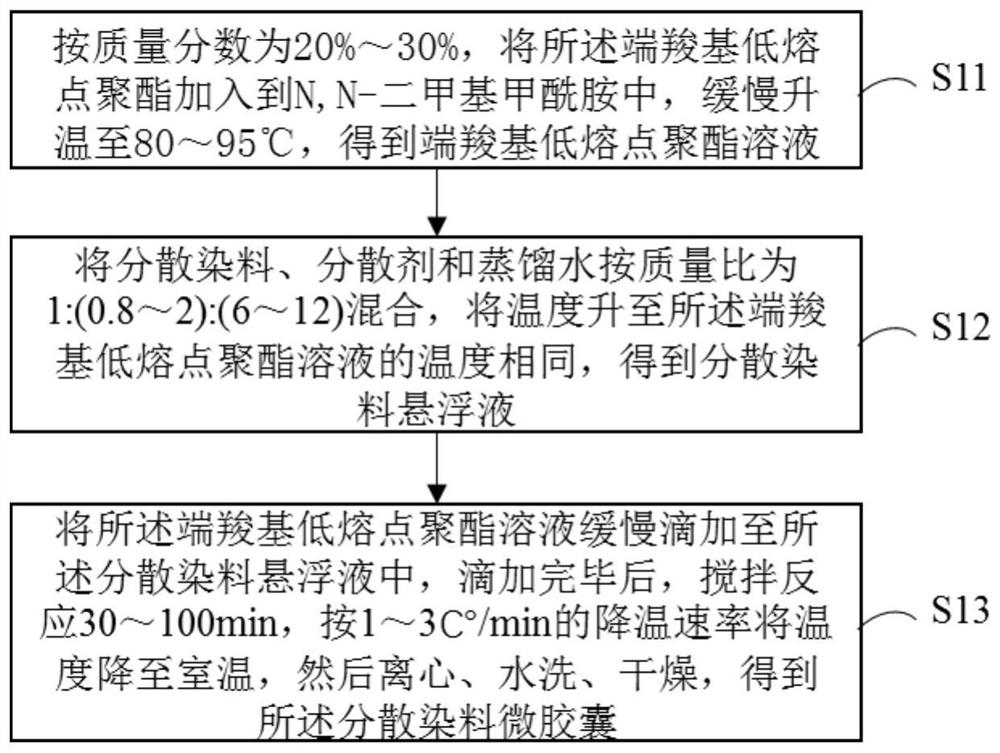

[0036] see figure 1 As shown, the specific preparation method of the mattress fabric dye is as follows:

[0037] S11. Weigh the carboxyl-terminated low-melting polyester and add it to N,N-dimethylformamide, slowly heat up to 90° C. to completely dissolve the carboxyl-terminated low-melting polyester, and obta...

Embodiment 2~11

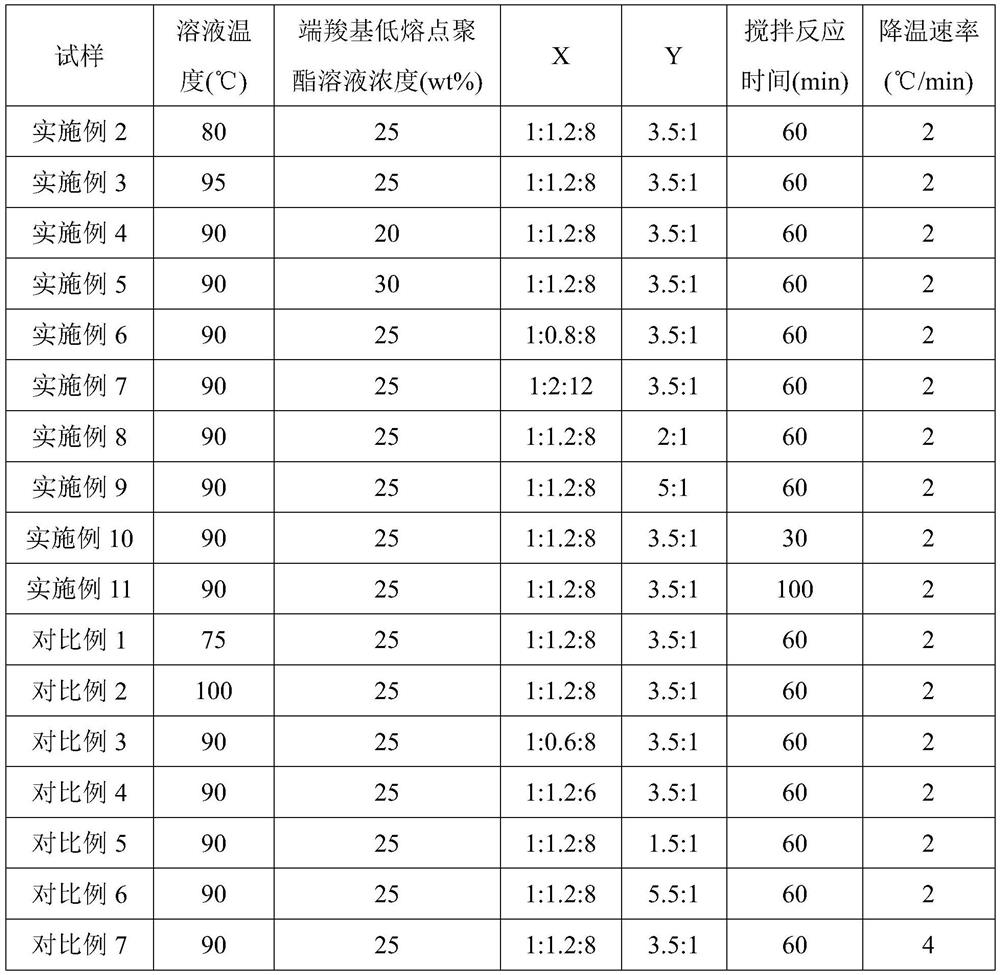

[0042] Compared with Example 1, the mattress fabric dyes provided in Examples 2 to 11 are different in that the preparation conditions of the disperse dye microcapsules are shown in Table 1, and the others are basically the same as those in Example 1, which will not be repeated here. Repeat. In Table 1, X represents the mass ratio of disperse dye, sodium methylenebisnaphthalene sulfonate and distilled water, and Y represents the mass ratio of carboxyl-terminated low-melting polyester to disperse dye.

Embodiment 12

[0056] A dyeing method for mattress fabric dyeing agent, using the disperse dye microcapsules prepared in Example 1 to dye polyester mattress fabrics, the specific method is as follows:

[0057] S21. Preparation of dye liquor: adding the disperse dye microcapsules prepared in Example 1 into distilled water to obtain a 3% (owf) disperse dye microcapsule dye liquor;

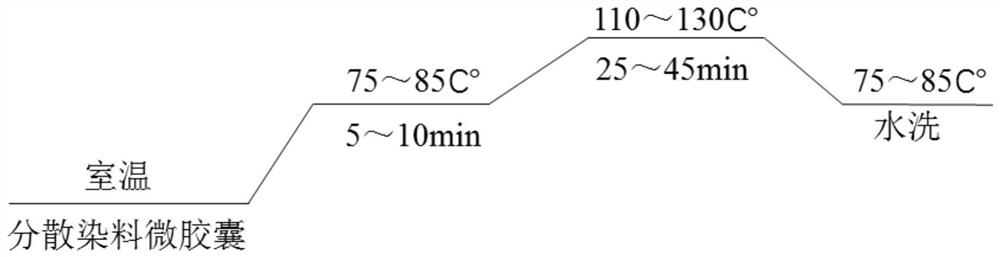

[0058] S22. Fabric dyeing: take a piece of polyester mattress fabric and put it in a dyeing tank, add the disperse dye microcapsule dyeing solution described in step S21 to the dyeing tank according to the liquor ratio of 1:20, and slowly heat up to 2°C / min to 80°C, hold for 8 minutes, then slowly heat up to 120°C at 2°C / min, hold for 45 minutes, and then slowly cool down to 80°C at 2°C / min;

[0059] S23. Fabric post-treatment: take out the dyed polyester mattress fabric, wash it with water and air dry to obtain the dyed polyester mattress fabric;

[0060] S24. Post-treatment of dye liquor: Slowly reduce the dye l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com