Full-dull elastic yarn and preparation method thereof

A kind of elastic yarn, full extinction technology, applied in the field of polyester fiber, can solve the problem of uneven strip shape, and achieve the effect of maintaining excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of full extinction elastic yarn, its process is as follows:

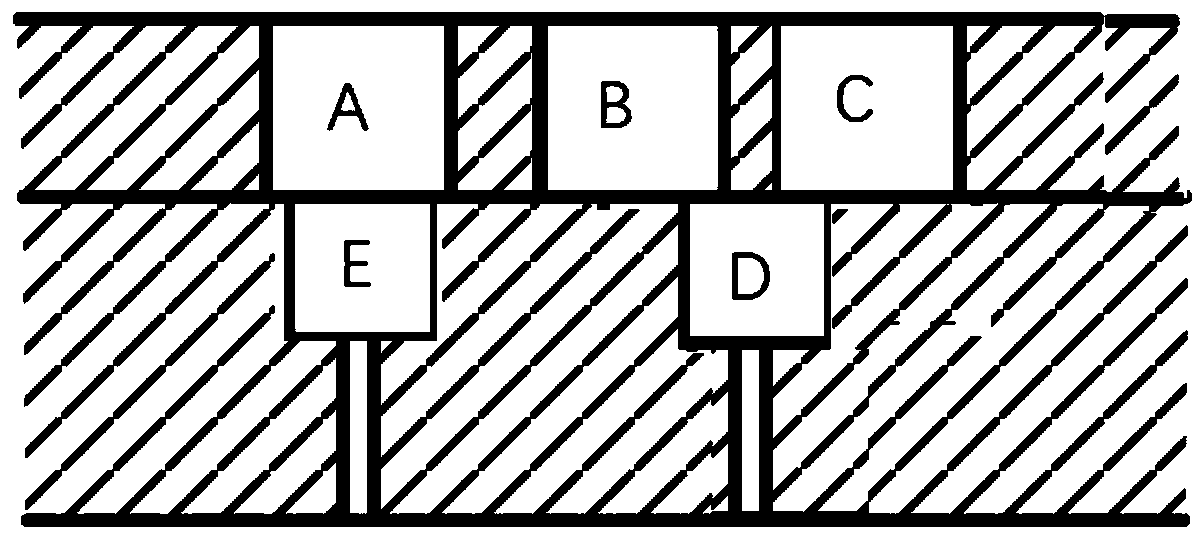

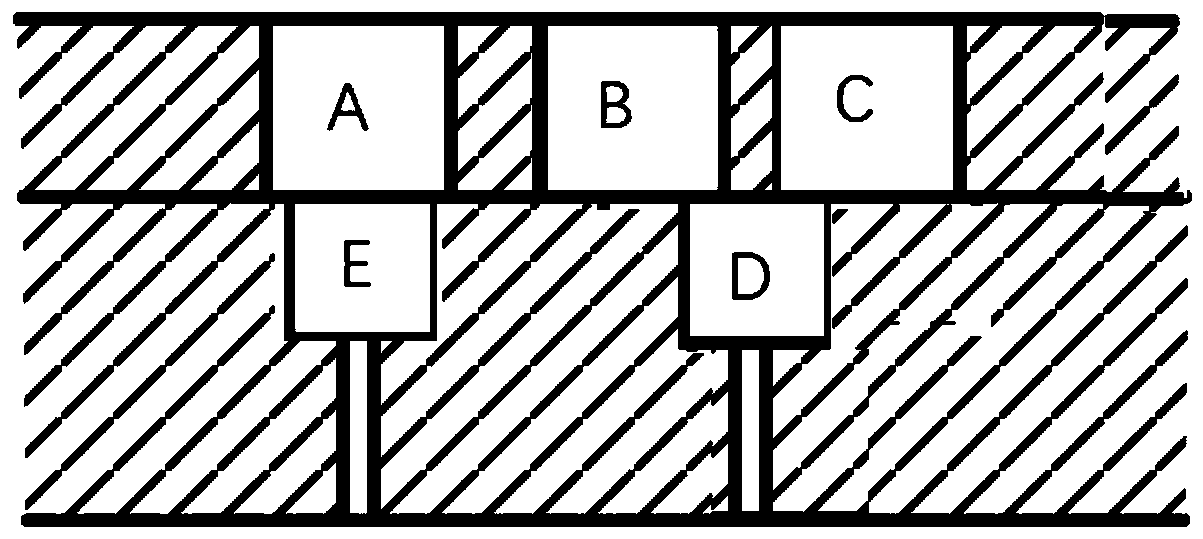

[0045] (1) The full-dull elastic yarn is extruded on the same spinneret, specifically:

[0046] PET melt (containing 2.9wt% TiO2) with intrinsic viscosity of 0.55dL / g 2 ) is split into two paths: one path is directly extruded after distribution; the other path is the PBT melt (containing 2.5wt% TiO2) with an intrinsic viscosity of 1.2dL / g 2 ) are extruded together after distribution according to the parallel composite spinning method;

[0047] The ratio of the number of spinneret holes m (hollow spinneret holes) that are directly extruded through to the number of spinneret holes n (circular spinneret holes) that are extruded through after being distributed in a parallel composite spinning manner 1:8;

[0048] The mass ratio of the PET melt passing through the spinneret n to the PBT melt is 50:50, and the ratio of the equivalent diameter of the spinneret m to the spinneret n is 1:1; ...

Embodiment 2

[0057] The preparation method of full extinction elastic yarn, its process is as follows:

[0058] (1) The full-dull elastic yarn is extruded on the same spinneret, specifically:

[0059] PET melt (containing 2.5wt% TiO 2 ) is split into two paths: one path is directly extruded after distribution; the other path is 1.16dL / g PBT melt (containing 2.5wt% TiO 2 ) are extruded together after distribution according to the parallel composite spinning mode;

[0060] The ratio of the number of spinneret holes m (hollow spinneret holes) that are directly extruded through to the number of spinneret holes n (circular spinneret holes) that are extruded through after being distributed in a parallel composite spinning manner 1:5;

[0061] The mass ratio of the PET melt passing through the spinneret n to the PBT melt is 50:50, and the ratio of the equivalent diameter of the spinneret m to the spinneret n is 1:1;

[0062] The outer edge of the cross-section of the hollow spinneret hole is ...

Embodiment 3

[0070] The preparation method of full extinction elastic yarn, its process is as follows:

[0071] (1) The full-dull elastic yarn is extruded on the same spinneret, specifically:

[0072] A PET melt with an intrinsic viscosity of 0.6dL / g (containing 2.5wt% TiO 2 ) is split into two paths: one path is directly extruded after distribution; the other path is 1.19dL / g PBT melt (containing 2.6wt% TiO 2 ) are extruded together after distribution according to the parallel composite spinning method;

[0073] The ratio of the number of spinneret holes m (hollow spinneret holes) that are directly extruded through to the number of spinneret holes n (circular spinneret holes) that are extruded through after being distributed in a parallel composite spinning manner 1:8;

[0074] The mass ratio of the PET melt passing through the spinneret n to the PBT melt is 50:50, and the ratio of the equivalent diameter of the spinneret m to the spinneret n is 1:1;

[0075] The outer edge of the cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com