Zizyphus jujube distilled wine and brewing process thereof

A technology of distilled wine and wild jujube, which is applied in the field of wine making, can solve the problems of low market acceptance, single flavor of wine, and uncoordinated taste of wild jujube distilled wine, and achieve the effect of good market prospects, clean wine body and harmonious wine aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

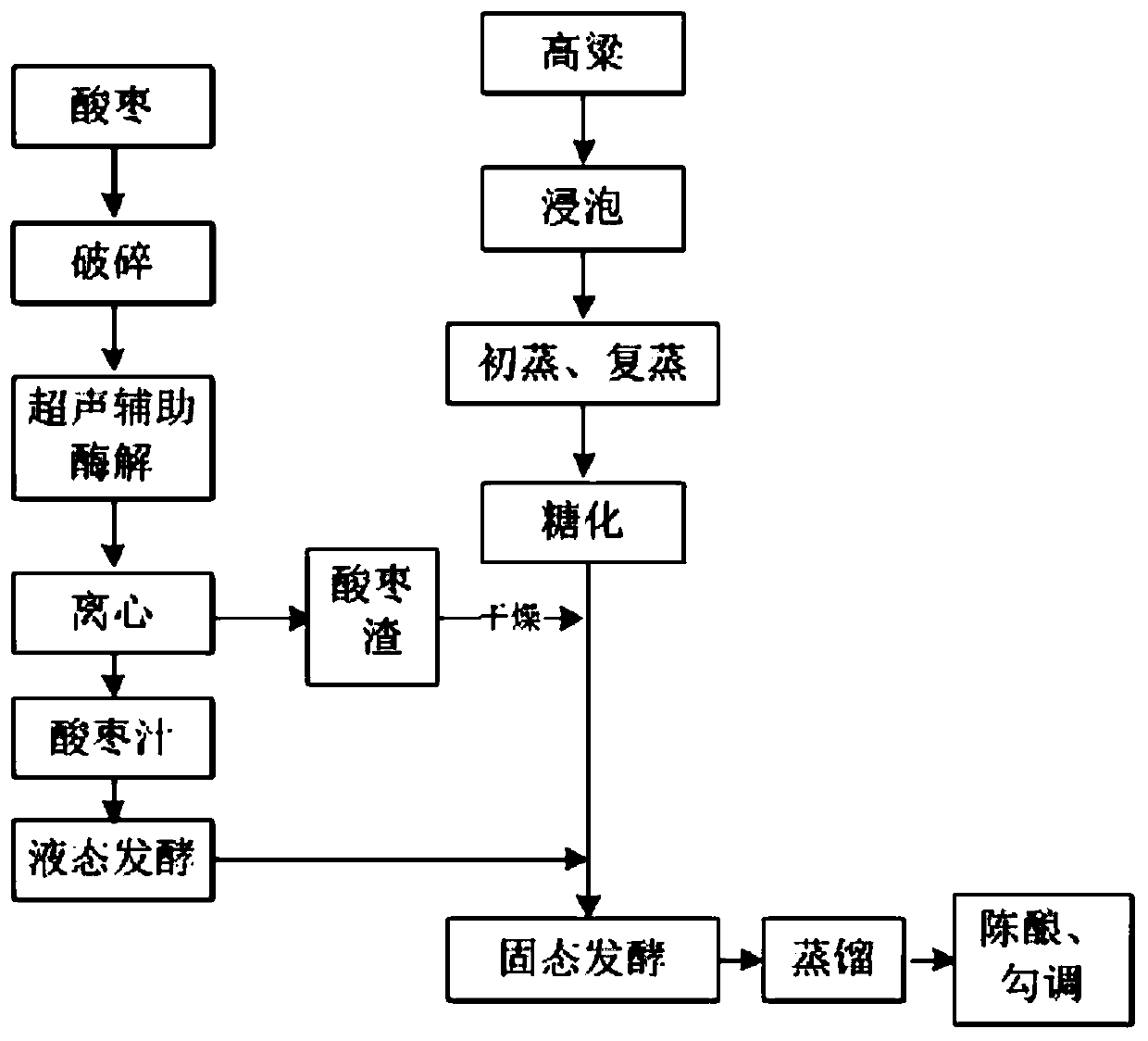

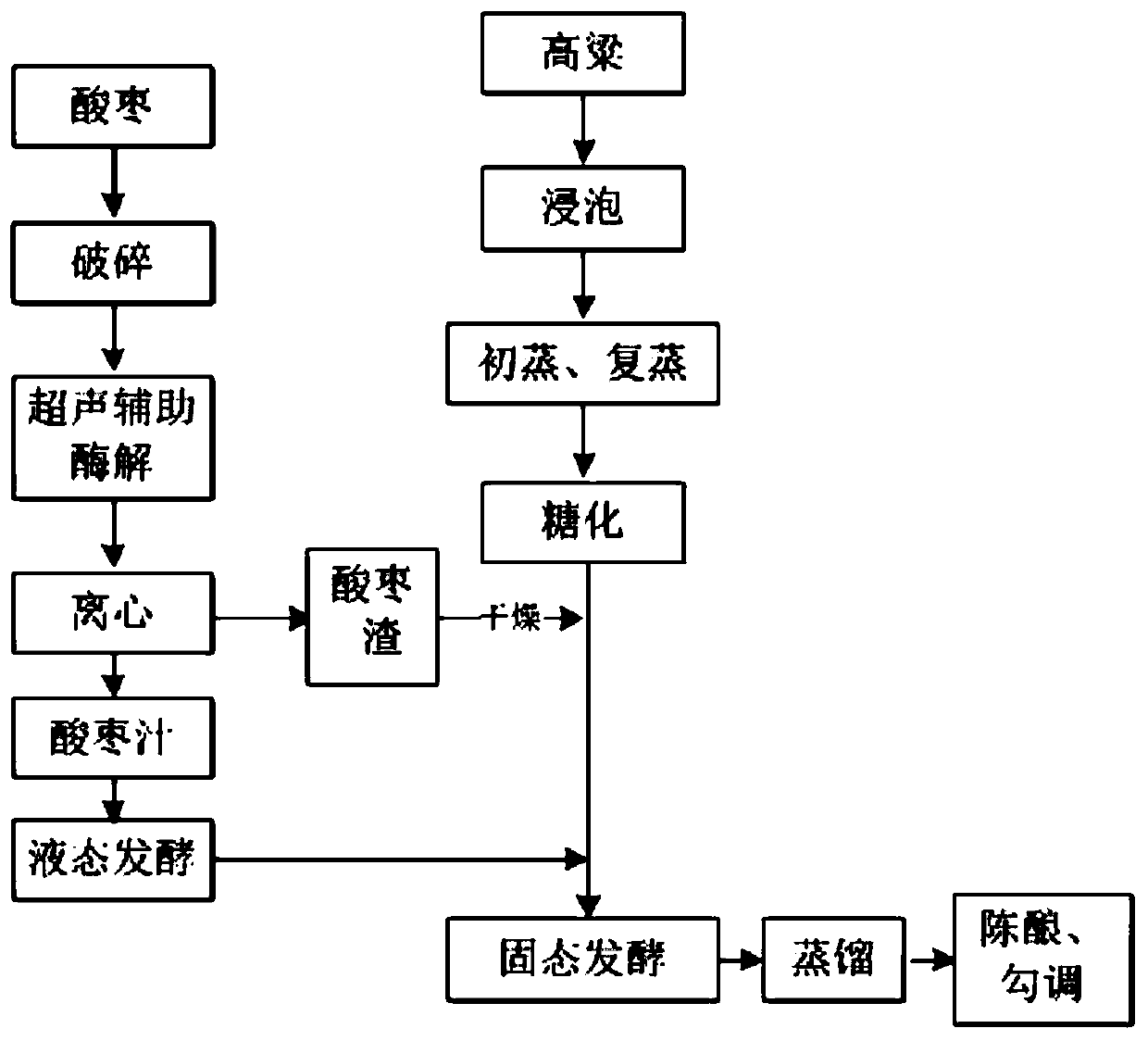

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment provides a kind of brewing process of jujube distilled wine, comprising the following steps:

[0058] Step 1. Raw material selection and impurity removal: select naturally mature and full-grained wild jujube in the mountainous area of southern Hebei, mechanically remove impurities such as jujube leaves and branches, manually select and remove diseased or rotten fruits, rinse repeatedly with tap water, and then use softener Spray water and drain; sorghum requires full grains, no mildew, no insects, no sediment and other impurities;

[0059] Step 2, Zizyphus jujube crushing: add pure water 4 times its mass to the jujube that has been drained, use a stirring crusher to crush it to a fineness of 3-8mm, add 0.5wt% of its mass to the crushed wild jujube Compound enzymes were subjected to discontinuous ultrasonic enzymolysis at a temperature of 50°C and a pH of 4.0. The enzymolysis time was 2.5 hours. After the enzymolysis was completed, a three-legged...

Embodiment 2

[0071] The present embodiment provides a kind of brewing process of jujube distilled wine, comprising the following steps:

[0072] Step 1. Raw material selection and impurity removal: select naturally mature and full-grained wild jujube in the mountainous area of southern Hebei, mechanically remove impurities such as jujube leaves and branches, manually select and remove diseased or rotten fruits, rinse repeatedly with tap water, and then use softener Spray water and drain; sorghum requires full grains, no mildew, no insects, no sediment and other impurities;

[0073] Step 2, Zizyphus jujube crushing: add purified water twice its mass to the jujube that has been drained, crush it to a particle size of 3-8mm with a stirring crusher, and add 0.6wt% compound enzyme of its mass to the crushed wild jujube , at a temperature of 45°C and a pH of 3.5, intermittent ultrasonic enzymolysis was carried out for 3 hours. After the enzymolysis was completed, a three-legged centrifuge was ...

Embodiment 3

[0085] The present embodiment provides a kind of brewing process of jujube distilled wine, comprising the following steps:

[0086] Step 1. Raw material selection and impurity removal: select naturally mature and full-grained wild jujube in the mountainous area of southern Hebei, mechanically remove impurities such as jujube leaves and branches, manually select and remove diseased or rotten fruits, rinse repeatedly with tap water, and then use softener Spray water and drain; sorghum requires full grains, no mildew, no insects, no sediment and other impurities;

[0087] Step 2, Zizyphus jujube crushing: add 3 times its mass of pure water to the drained wild jujube, use a stirring crusher to crush it to a particle size of 3-8mm, and add 0.3wt% of its mass to the crushed wild jujube compound enzyme , at a temperature of 55°C and a pH of 3.8, intermittent ultrasonic enzymolysis was carried out for 2 hours. After the enzymolysis was completed, a three-legged centrifuge was used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com