Method for preparing cross-linked acid

A technology of cross-linking acid and cross-linking agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of limited communication reservoir range, short acid corrosion cracks, and poor effect of slow acid fracturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

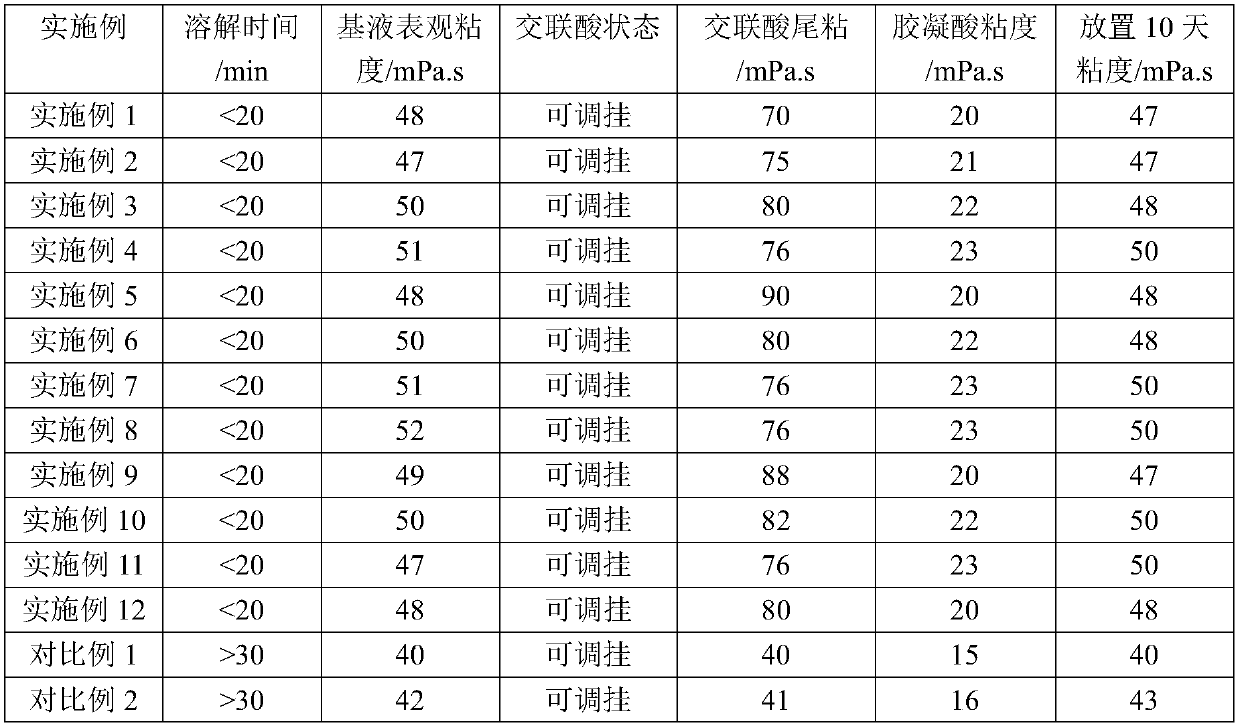

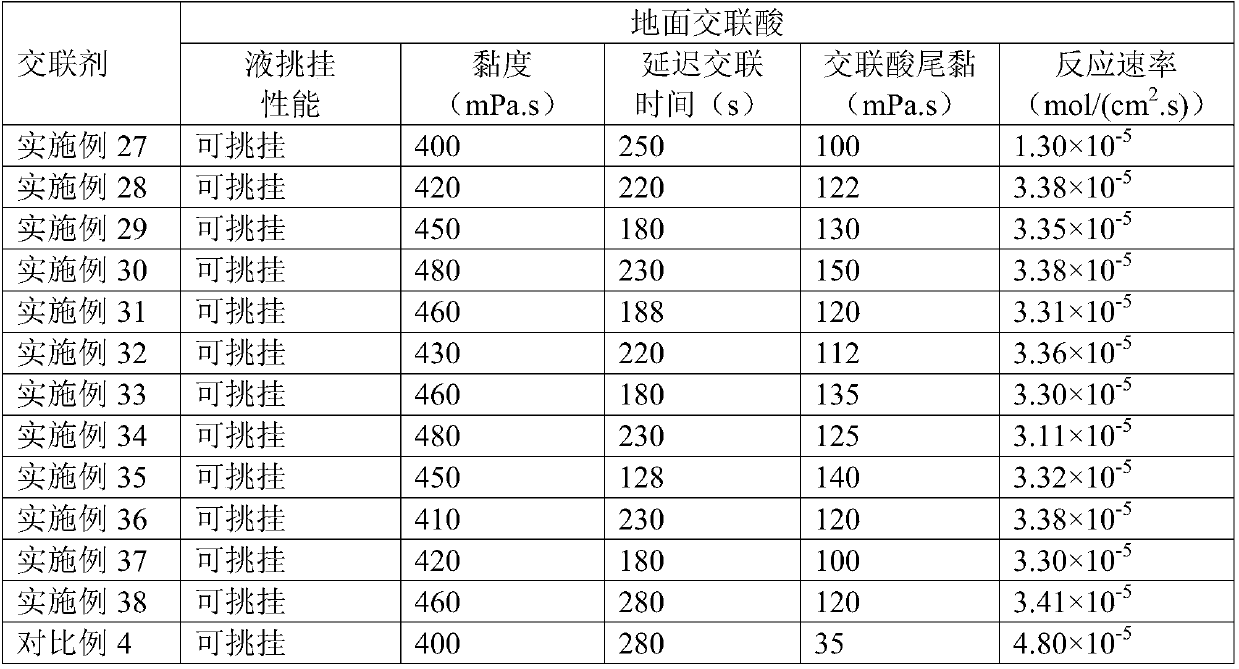

Examples

Embodiment 1

[0085] 1) Configure an aqueous solution of polymerized monomers, in parts by mass, 35 parts of acrylamide, 64 parts of 2-acrylamide-2-methylpropanesulfonic acid monomer (AMPS), 1.4 parts of N,N-dimethylacrylamide, Add 0.3 parts of cetyldimethylallylammonium chloride monomer into a beaker, add distilled water to dissolve, and make the total mass content of the four types of monomers be 25wt%;

[0086] 2) Add 1.0% urea, 0.05% sodium formate, 0.03% tetrasodium ethylenediaminetetraacetic acid, and 3.0% sodium lauryl sulfate to the above monomer aqueous solution (based on the total mass of the four monomers as 100%), 0.05% ethylenediamine, stir and dissolve evenly, put it in a 5°C water bath and cool for 30min, and let the temperature cool down to 5°C;

[0087] 3) Add a certain amount of sodium carbonate to the above solution to adjust the pH value of the solution to 9, continue to cool for 30 minutes, put it in a 5°C water bath to cool the temperature to 5°C, introduce the liquid ...

Embodiment 2

[0092] 1) Prepare an aqueous solution of polymerized monomers, in parts by mass, 45 parts of acrylamide, 53 parts of acryloyloxyethyltrimethylammonium chloride (DAC), 1.7 parts of methacryloyloxyethyldimethylamine, Add 0.6 parts of methacryloyloxyethyl dimethyl cetyl ammonium bromide monomer into a beaker, add distilled water to dissolve, so that the total mass content of the four types of monomers is 29wt%;

[0093] 2) Add 3.0% thiourea, 0.08% potassium formate, 0.05% disodium ethylenediamine tetracarboxylate, 5.0% dodecyl sulfonate to the above monomer aqueous solution (based on the total mass of the four monomers as 100%) sodium nitrate, 0.1% N,N-tetramethylethylenediamine, stir and dissolve evenly, put it in a 10°C water bath and cool for 30min, and cool the temperature to 10°C;

[0094] 3) Add a certain amount of sodium carbonate to the above solution to adjust the pH value of the solution to 9.5, continue to cool for 30 minutes, put it in a 10°C water bath to cool the te...

Embodiment 3

[0099] 1) Prepare an aqueous solution of polymerized monomers, in parts by mass, mix 40 parts of acrylamide, 58 parts of DAC, 1.5 parts of methacryloyloxyethyl dimethylamine, 0.5 parts of methacryloyloxyethyl dimethyl Add the hexaalkylammonium bromide monomer into the beaker, add distilled water to dissolve, so that the total mass content of the four types of monomers is 27wt%;

[0100] 2) Add 2.0% thiourea, 0.04% potassium formate, 0.03% disodium ethylenediaminetetraacetic acid, 4.0% dodecyl sulfonate to the above aqueous monomer solution (based on the total mass of the four monomers as 100%) Sodium bicarbonate, 0.08% N,N-tetramethylethylenediamine, stir and dissolve evenly, put it in a water bath at 8°C and cool for 30 minutes, and cool the temperature to 8°C;

[0101]3) Add a certain amount of sodium carbonate to the above solution to adjust the pH value of the solution to 10, continue to cool for 30 minutes, put it in an 8°C water bath to cool the temperature to 8°C, intro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com