Perfluoropolyether carboxylic acid with low HF content and preparation method thereof

A technology of perfluoropolyether carboxylic acid and perfluorocarboxylic acid, applied in the field of fluorine chemical industry, can solve problems such as affecting the quality of perfluoropolyether carboxylic acid, and achieve the effect of reducing HF and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

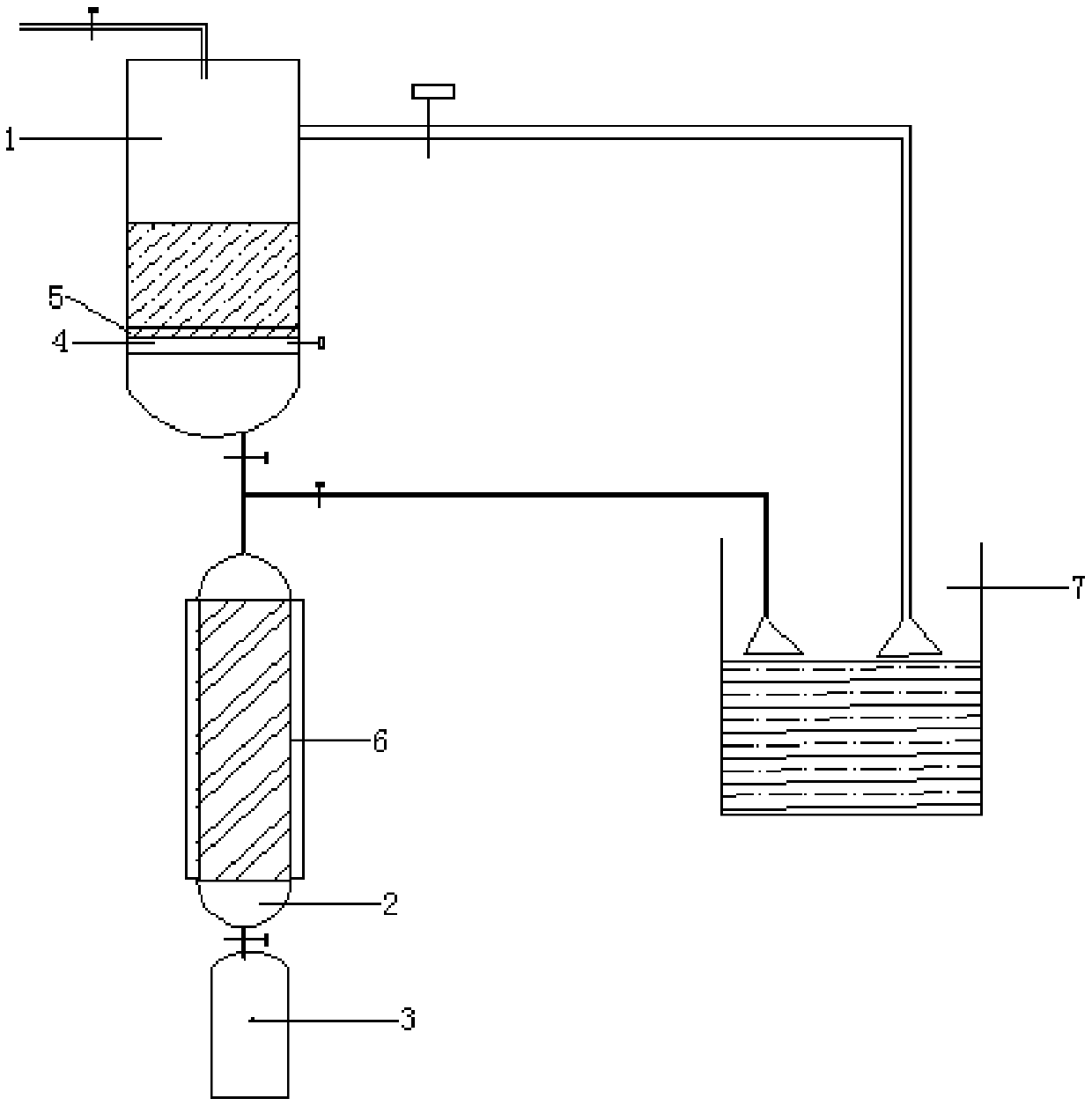

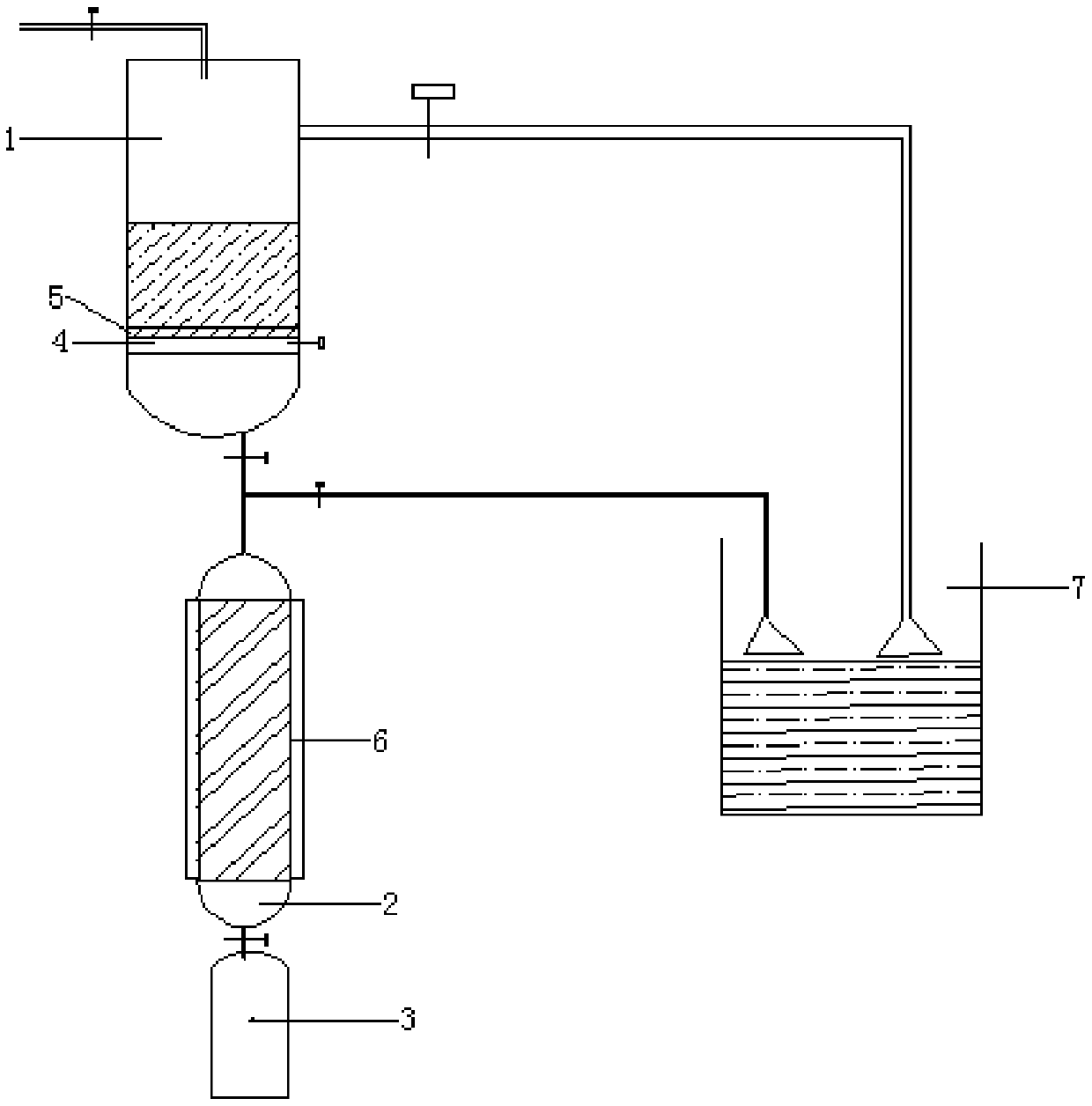

Image

Examples

Embodiment 1

[0015] Example 1: In a reaction tank, add 100 grams of perfluoropolyetheracyl fluoride CF3CF2CF2OCF(CF3)-COF at 0°C to 10°C, keep the temperature and add 115g of NaF in a saturated aqueous solution at a speed of 1-10ml / min, Without stirring, after the reaction is over, open the partition in the reaction tank, the reaction product flows into the absorption tower containing the NaF recovery agent through the filter screen set on the partition, and a small amount of NaHF2 stays on the filter screen, and a large amount of HF generated The gas enters the NaOH recovery tank through the gas outlet above the reaction tank to complete the recovery of a large amount of HF gas. The product CF3CF2CF2OCF(CF3)-COOH containing a small amount of HF enters the absorption tower, and HF reacts with NaF to generate NaHF2. After absorbing HF, the gas CF3CF2CF2OCF(CF3)-COOH enters the storage tank of perfluoropolyether carboxylic acid, and the content of HF in the final CF3CF2CF2OCF(CF3)-COOH is les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com