Process for preparing livestock and poultry manure organic fertilizer by using energy chemical technology

A technology of livestock and poultry manure and organic fertilizer, which is applied in the field of preparing livestock and poultry manure organic fertilizer using energy and chemical technology, can solve the problems of affecting the growth of working plants, cumbersome treatment process, land pollution, etc., and achieves novel structure, optimized fermentation process, The effect of saving volume waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

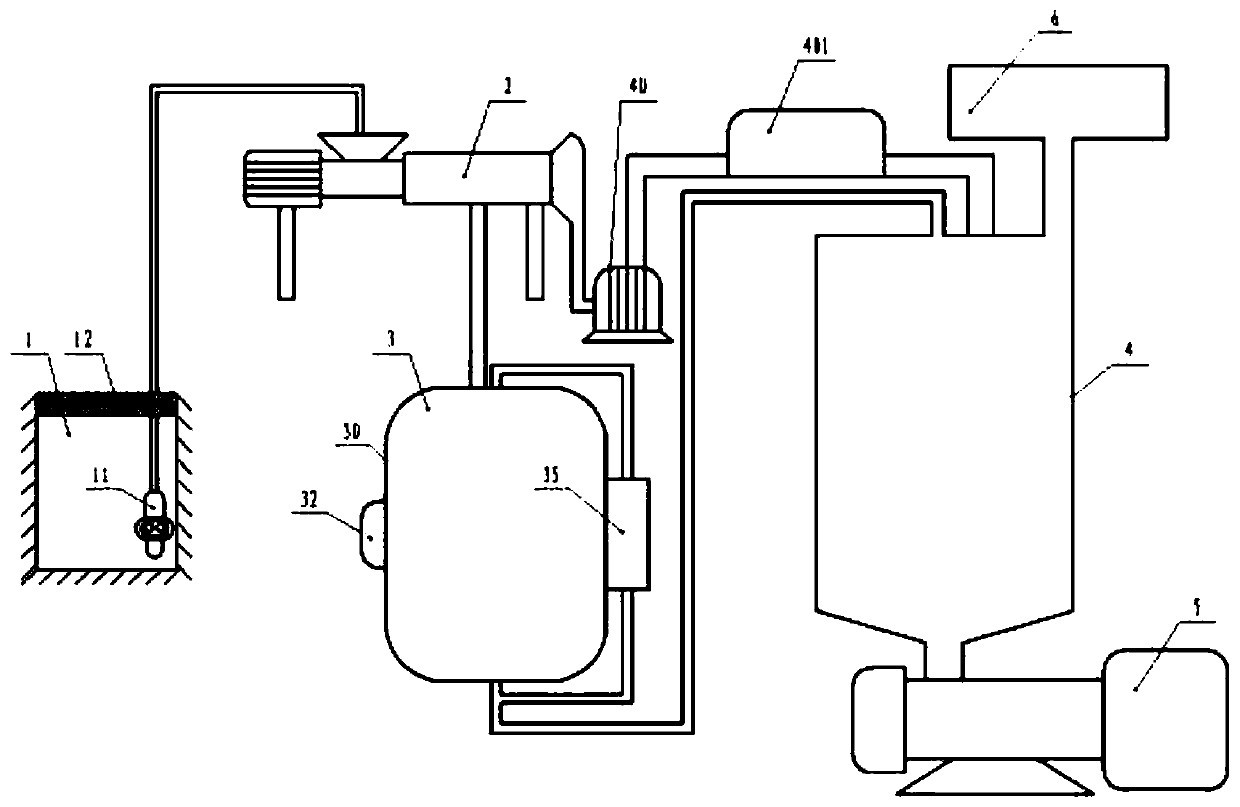

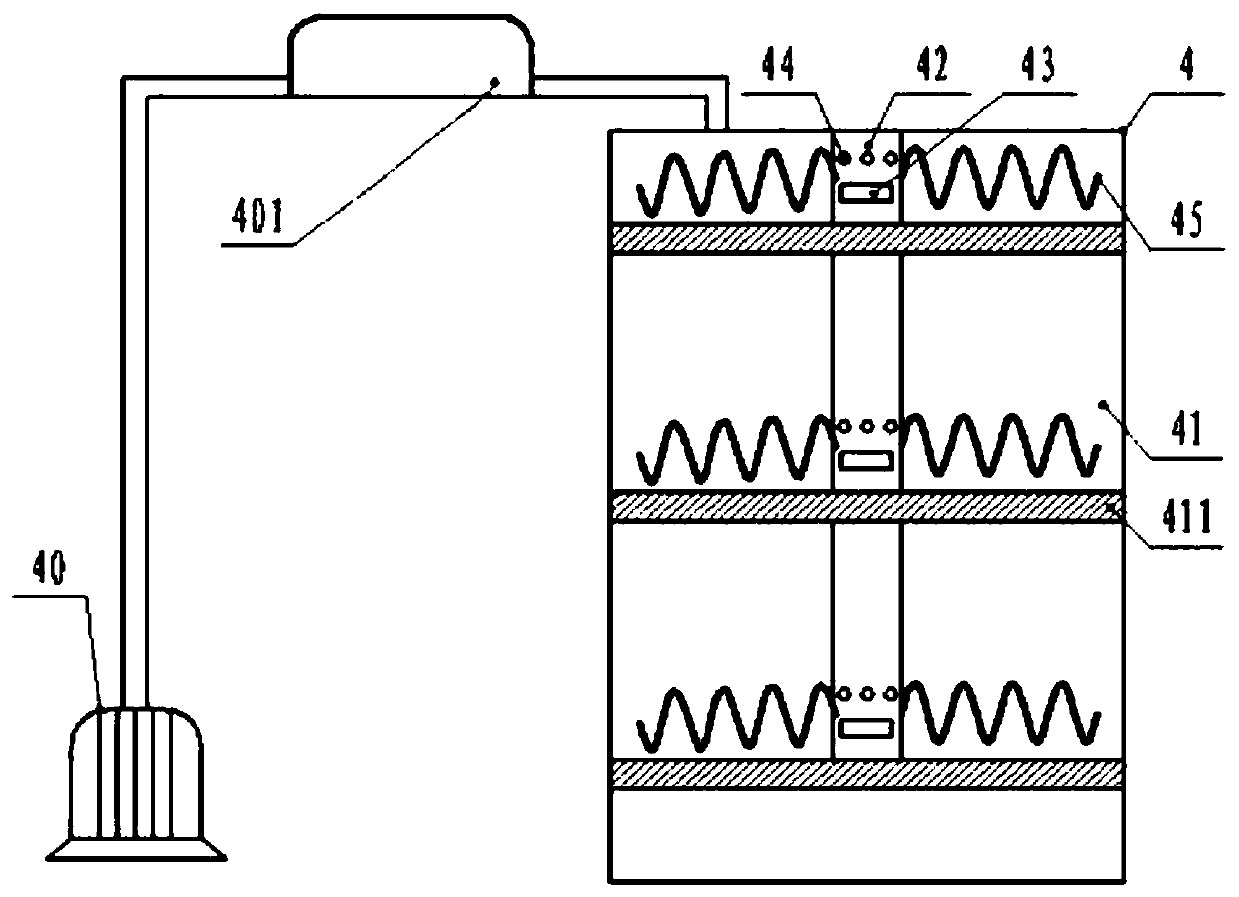

[0026] In order to facilitate the understanding of the technical solution of the present invention, the following in conjunction with the attached Figure 1-4 The present invention will be further explained with specific examples, and the examples are not intended to limit the protection scope of the invention.

[0027] A process for preparing livestock and poultry manure organic fertilizer using energy and chemical technology mainly includes the following steps:

[0028] S1: Transfer the collected livestock and poultry manure to the solid-liquid separator 2 for solid-liquid separation through the delivery pump 11 arranged in the livestock and poultry manure tank 1, and transport the separated liquid manure to the electrolytic reactor 3;

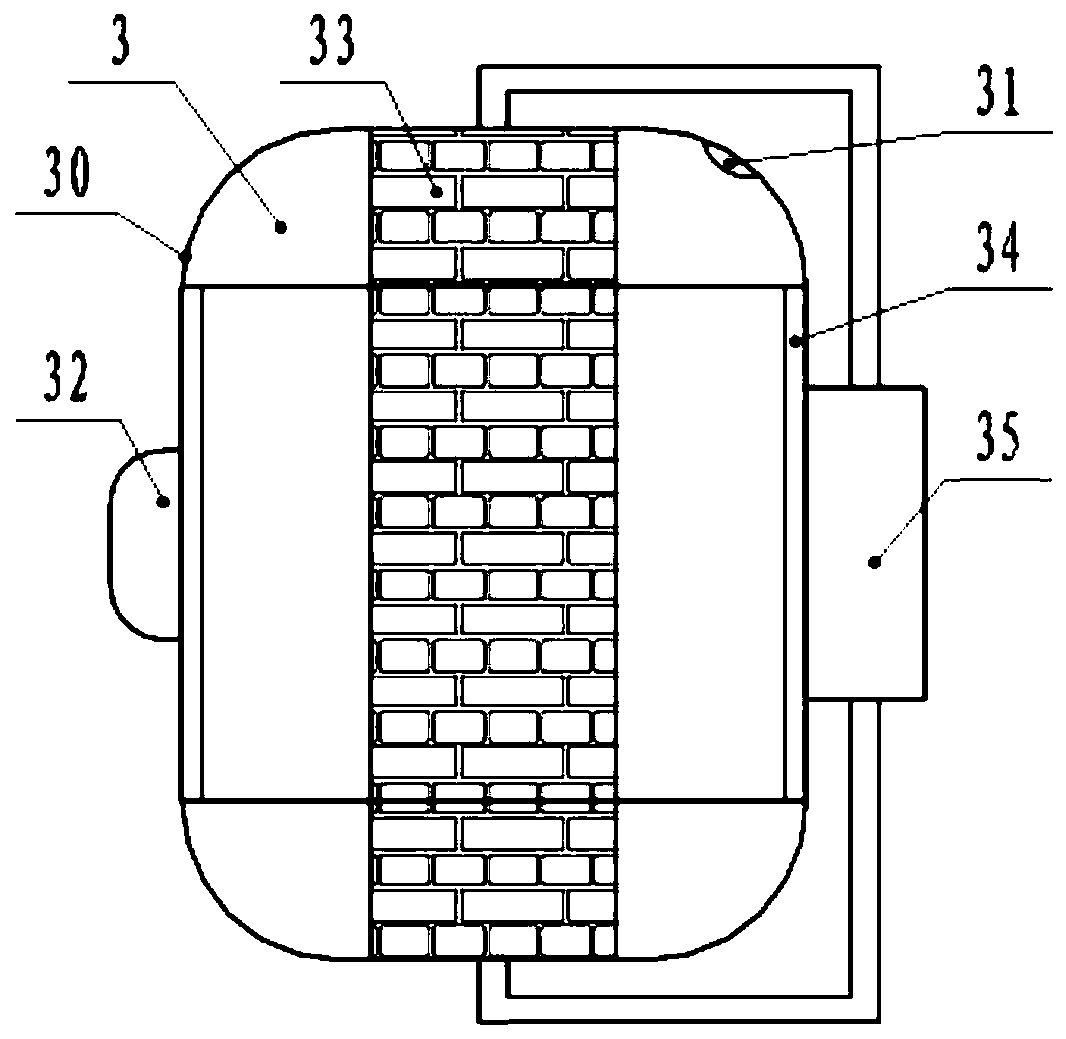

[0029] S2: After the separated liquid manure fills the electrolytic reactor 3, the liquid level sensor 31 sends an electrical signal to the current controller 32, and the current controller 32 communicates with the anode and the cathode in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com